-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

Mandrel-Free Tube and Profile Bender CORMAK BENDMASTER 80 – automatic bending of large-diameter steel tubes

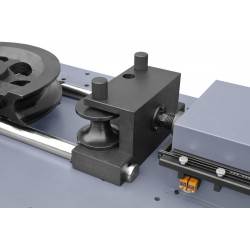

The Mandrel-Free Tube and Profile Bender CORMAK BENDMASTER 80 is a technologically advanced machine designed for bending thick steel tubes and profiles in both automatic and manual modes. With its powerful drive, hydraulic clamping system, and integrated digital angle display, the bender ensures maximum repeatability, precision, and operational safety – without the need for a mandrel or sand filling. It is ideal for serial production and heavy-duty industrial applications where maximum reliability and bending quality are required.

Main advantages of the machine

- Mandrel-free bender – eliminates the need for an internal mandrel, reducing setup time and eliminating material damage risk.

- Main motor 5.5 kW – provides sufficient torque for bending large-diameter tubes.

- Hydraulic pressure shoe – automatically adjusted to the tube diameter, ensuring precise support during bending.

- Automatic and manual operation modes – flexibility to suit production type and process control.

- Digital bending angle display – real-time control of bending parameters via the operator panel.

- Dies for 60.3 mm and 76.1 mm tubes – ready for the most demanding tube diameters and large bending radii.

- Maximum bending angle 180° – enables full arcs and closed shapes.

Construction and technology

The BENDMASTER 80 model features two independent drive systems: a 5.5 kW main motor powering the gearbox and bending die, and a 1.1 kW hydraulic pump motor for the automatic pressure shoe system. An adjustable limit switch allows the clamping force and range to be adapted to the tube diameter. The digital display shows both the target and current bending angles, ensuring full process control. The robust, steel-welded frame with a total weight of 1,500 kg guarantees stability and vibration resistance during operation.

Precision and performance

The BENDMASTER 80 tube and profile bender provides accurate bending of steel tubes without the need for cutting or filling. The 2 rpm die rotation speed is optimised for precision and control. The automatic mode allows serial bending of repeatable parts with minimal operator involvement, while the manual mode is ideal for single-piece or custom work. The machine performs perfectly when bending large-diameter steel tubes in demanding production environments.

Applications

This machine has been designed for continuous operation in industrial environments. The BENDMASTER 80 excels in:

- production of industrial and heating installations,

- bending steel tubes in structural and construction sectors,

- forming of large-diameter components for fences, gates, and handrails,

- serial bending of thick-walled tubes and profiles in metalworking and prefabrication workshops.

Standard equipment

- Digital bending angle display

- Hydraulic pressure shoe with adjustable limit switch

- Dies for tubes:

- Ø 60.3 mm – R=420 mm (3.5D)

- Ø 76.1 mm – R=530 mm (3.5D)

Technical data

| Maximum bending angle |

180° |

| Die rotation speed during bending |

2 rpm |

| Main motor power |

5.5 kW |

| Hydraulic pump motor power |

1.1 kW |

| Machine dimensions |

1450 × 790 × 900 mm |

| Weight |

1500 kg |

Increase the efficiency and precision of your steel tube bending – choose the mandrel-free bender BENDMASTER 80. Contact our technical department to select the configuration tailored to your production requirements.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

3 other products in the same category:

Write your review

* Required fields

I accept privacy policy rules