-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

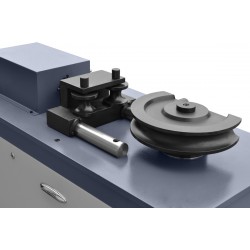

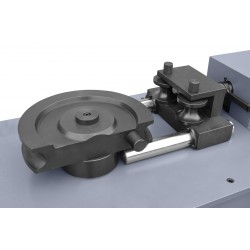

Mandrel-Free Tube and Profile Bender CORMAK BENDMASTER 50 – automatic steel tube bending with precise hydraulic clamping

The Mandrel-Free Bender BENDMASTER 50 is an industrial-grade machine designed for bending steel tubes and closed profiles without using an internal mandrel. Its integrated hydraulic pressure system, two working modes – automatic and manual – and digital bending angle display provide outstanding precision, repeatability, and ergonomics. Perfect for serial production, pipe prefabrication, and workshops requiring high control over the bending process.

Main advantages of the machine

- Mandrel-free bender – bends tubes and profiles without deformation, eliminating the need for an internal mandrel.

- Hydraulic shoe pressure system – precise pressure force automatically adjusted to tube diameter.

- Two operating modes: automatic and manual – full control over the bending process, with programmable or manual operation.

- Digital angle display – real-time information on target and actual bending angle via the operator panel.

- Main motor 2.2 kW – stable die rotation even for large tube diameters.

- Die set for tube diameters 25, 32, 38, and 48.3 mm – ready for the most common steel tube sizes.

- Bending angle up to 180° – allows for full bends and closed loop elements.

Construction and technology

BENDMASTER 50 is equipped with two independent motors: a 2.2 kW main motor for the geared drive and die rotation, and a 1.1 kW hydraulic pump motor for the pressure shoe system. The pressure is automatically applied in programmed mode, controlled by an adjustable limit switch. This configuration ensures optimal clamping parameters for every tube diameter, directly affecting bending quality and repeatability. The control panel includes a clear digital display showing both the set and actual bending angles.

Precision and performance

The BENDMASTER 50 tube and profile bender provides a full bending range up to 180° while maintaining high accuracy. The 5 rpm die rotation speed guarantees precise shaping and production efficiency. The automatic mode enables batch bending with minimal operator input, while the manual mode provides flexibility for customised settings. The machine is ideal for bending medium and large-diameter steel tubes in serial production environments.

Applications

The Mandrel-Free Bender BENDMASTER 50 is suitable for a wide range of industries, including:

- pipe installation production in sanitary, heating, and industrial sectors,

- prefabrication of balustrades, handrails, and structural frames,

- manufacture of metal furniture and decorative components,

- serial bending of steel elements in metalworking and construction workshops.

Standard equipment

- Digital bending angle display

- Dies for tube diameters:

- 25 mm (radius 90 mm)

- 32 mm (radius 114 mm)

- 38 mm (radius 134 mm)

- 48.3 mm (radius 170 mm)

Technical data

| Maximum bending angle |

180° |

| Die rotation speed during bending |

5 rpm |

| Main motor power |

2.2 kW |

| Hydraulic pump motor power |

1.1 kW |

| Machine dimensions |

1145 × 580 × 980 mm |

| Weight |

620 kg |

Invest in full control over your bending process – choose the mandrel-free bender BENDMASTER 50 and optimise your tube and profile production. Contact our technical advisor to select the best configuration for your production line.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

3 other products in the same category:

2024-11-30

Giętarka BRNDMASTER 50

Dobra maszyna. Były zaraz po zakupie pewne problemy, nie z maszyną. Ale giętarka godna polecenia. Ciężka stabilna, wszystko działa tak jak należy. Żeby efekty pracy były pozytywne, należy giętarkę wypoziomować. Godna polecenia. A klientem jestem wymagającym.