- Reduced price

The basket is empty.

The set includes a LUFT 700 screw compressor, a vertical air receiver with fittings for compressed air with a capacity of 200L, and an IZBERG N10S dryer. The CORMAK LUFT series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low operating costs, ease of use, ergonomic and robust design, and high performance ensure efficient and trouble-free operation.

Looking for a professional solution for powering pneumatic tools in your workshop, paint shop or small production line? The CORMAK LUFT 700 screw compressor is the ideal choice. With a power of 5.5kW and an impressive actual capacity of up to 690 L/min, it provides a constant supply of compressed air essential for efficient operation of impact wrenches, blow guns and spray tools.

This model is designed for continuous operation, making it perfect for demanding applications such as tyre service centres, smaller car workshops and small manufacturing plants. Investing in the CORMAK screw compressor means significantly improving your working comfort – say goodbye to noisy piston compressors and enjoy quieter, more stable operation.

The LUFT 700 features a direct drive which offers greater efficiency and reduced power losses compared with belt-driven models. This innovative design ensures optimal utilisation of the motor power and consequently higher efficiency with lower energy consumption.

The maximum pressure generated by this screw compressor is 10 bar. Full control over the operating parameters is ensured by the intuitive electronic control panel from the MAM series, which provides access to key compressor information, increasing flexibility and process control.

✅ Pressure: up to 10 bar | ✅ Capacity: up to 690 L/min | ✅ Power: 5.5kW

Looking for solutions that exceed market standards? CORMAK screw compressors are synonymous with innovation and reliability, designed for the most demanding applications.

CORMAK: Technology that drives your success!

The combination of proven induction motor reliability and intelligent control makes the screw compressor a highly efficient, economical and flexible source of compressed air – perfectly suited to the dynamic needs of modern industry.

High-class CORMAK screw compressors, such as the LUFT 700 model, are built around technologically advanced screw modules that ensure their performance and reliability. By combining proven solutions with innovation, CORMAK ensures that each module is refined in every detail to meet the demands of intensive use.

Key features of the screw modules in CORMAK compressors:

In CORMAK screw compressors such as the LUFT 700 model, a key element ensuring reliability and work optimisation is the advanced MAM-series control panel. Designed for efficient management of the compressed-air system, this controller enables continuous monitoring and quick response to all operating parameters.

What does the CORMAK control panel offer?

When purchasing our compressor, you receive full documentation allowing easy registration of the unit with the Technical Inspection Office. Remember that UDT registration is required.

The documentation includes:

Remember!

By choosing our offer, you receive equipment directly from the manufacturer with many years of experience in compressor sales.

| Motor power | 5.5 kW |

| Voltage | 400 V / 50 Hz |

| Dimensions | 810 × 610 × 850 mm |

| Weight | 120 kg |

| Capacity | 0–6 bar – average 690 L/min At 6 bar – 650 L/min At 8 bar – 650 L/min At 10 bar – 630 L/min |

| Outlet connection (G) | 1/2" |

The CORMAK compressed-air dryer is a professional industrial device designed for effective removal of moisture, water vapour and oil particles from pneumatic systems. Using efficient refrigeration technology, the air dryer ensures stable operation of air-powered equipment, increasing its durability and reliability. It is the ideal solution for companies seeking modern air-treatment methods in pneumatic installations.

The refrigeration dryer is engineered for maximum efficiency and durability. The main structural elements include:

In the first stage, inlet air passes through the heat exchanger, where it is pre-cooled by the colder air leaving the evaporator. The counter-flow design increases overall energy efficiency.

In the second stage, compressed air enters the evaporator, where it is cooled to a dew-point temperature of 3 °C. This causes the contained water vapour and oil particles to condense.

After cooling, the mixture of gas and condensate passes into an efficient separator where the liquid is removed and automatically discharged from the unit.

The variable-speed fan technology intelligently adjusts cooling intensity to actual demand, reducing energy use and extending component life.

Thanks to refrigeration technology, the CORMAK compressor dryer effectively removes water and oil, protecting installations from corrosion, actuator seizure and pneumatic-tool damage. The constant dew-point temperature guarantees consistent air quality, ensuring reliability of the entire pneumatic system.

The CORMAK air dryer for compressors is used across a wide range of industrial sectors where clean, dry air is crucial for correct machine operation. Typical applications include:

| Parameter | Value |

|---|---|

| Inlet / outlet pipe diameter (BSP) | 1" |

| Maximum working pressure | 10 bar |

| Maximum inlet-air temperature | ≤ 38 °C |

| Dew-point temperature | 3 °C |

| Capacity | 1 500 L/min |

| Power | 0.58 kW |

| Supply voltage | 230 V |

| Dimensions (L × W × H) | 380 × 600 × 625 mm |

| Weight | 31 kg |

| Type and quantity of refrigerant | R134a, 400 g |

By choosing the CORMAK refrigeration air dryer, you invest in stability and efficiency of your pneumatic system. This unit is an essential element of any professional compressed-air network — particularly where high air purity and machine protection against corrosion and failure are required.

Do not risk losses caused by moisture in the pneumatic system — choose a CORMAK air-dryer and gain full control over your air quality!

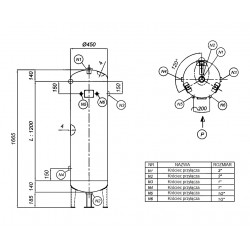

The CORMAK pressure vessel with a capacity of 200 litres and working pressure of 11 bar is a reliable solution designed for storing compressed air in industrial plants, workshops and pneumatic installations. The solid steel construction, compliance with European Union directives and UDT certification make this tank an indispensable element of any compressed-air system. Thanks to its optimised design and high pressure resistance, the tank serves both as a storage buffer and as a stabilising element for compressor operation parameters.

This compressed air tank has been designed for intensive use in industrial environments. The body made of structural steel with 4mm wall thickness guarantees resistance to pressures up to 11 bar and long service life. All welds are subjected to strict quality control, and the tank surfaces are protected with anti-corrosion paint resistant to chemical and atmospheric agents.

The tank is equipped with a nameplate with CE mark and the number of the notified UDT unit, confirming its approval for operation on the European market. The set includes complete technical documentation, passport and material certificates.

Thanks to its large 200L capacity, the tank acts as an air buffer, stabilising pressure throughout the entire pneumatic system. This enables smooth operation of air-powered equipment and significantly extends compressor lifespan by reducing the number of start and stop cycles. The vertical design allows compact installation, which is particularly beneficial for facilities with limited space.

A properly selected compressor tank minimises pressure drops and prevents pneumatic-system overloads, improving both efficiency and safety of the entire installation.

CORMAK pressure vessels are widely used across various industrial sectors as well as in car workshops, manufacturing plants, construction companies and central compressed-air systems. Thanks to their capacity and pressure resistance, they serve as:

| Weight (kg) | 80 |

| Connections | 6 |

| Connection size | 1/2", 1", 2" |

| Dimensions | 166.5 × 45 cm |

| Tank capacity (L) | 200 |

| Working pressure (bar) | 11 |

| Wall thickness (mm) | 4 |

| Diameter (mm) | Ø 450 |

| Height (mm) | 1665 |

If you are looking for an air receiver that guarantees reliability, UDT compliance and high operational efficiency for your pneumatic installation, the CORMAK 200L model is the ideal choice. We offer not only a product, but also full technical support, spare parts availability and professional advice on selecting the right compressor tank.

Order your CORMAK pressure vessel today to increase the efficiency and safety of your workshop or plant. Contact our technical department or place your order online!

Contact us to order a unit tailored to your needs!

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Screw Compressor with IZBERG N10S Dryer and 300L Vertical Tank CORMAK THEOR 10 750L/min 7.5kW

The set includes the THEOR 10 screw compressor, a vertical 300L compressed-air tank and the CORMAK IZBERG N10S air dryer. The screw compressor from the CORMAK THEOR series features state-of-the-art pneumatic solutions combined with high-quality materials and components. Low operating ...More

Screw Compressor with IZBERG N10S Dryer and 270L Vertical Tank CORMAK LUFT 700 650L/min 5.5kW

The set includes a LUFT 700 screw compressor, a vertical air receiver with fittings for compressed air with a capacity of 270 L , and an IZBERG N10S dryer. The CORMAK LUFT series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low ...More

Screw Compressor CORMAK THEOR 30 + 500L Vertical Tank + IZBERG N50S Dryer

The set includes the THEOR 30 screw compressor, a vertical compressed air receiver with a capacity of 500L , and the air dryer IZBERG N50S . The CORMAK THEOR series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low operating costs, ...More

Screw Compressor with Inverter, IZBERG N75S Dryer and 1000L Vertical Tank CORMAK THEOR 75 55kW

Set including the THEOR 75 INVERTER screw compressor equipped with an inverter by CORMAK , a vertical compressed air receiver with a capacity of 1000L , and an air dryer IZBERG N75S . The CORMAK THEOR series screw compressors combine the latest pneumatic technologies with high-quality ...More

Screw Compressor with N10S Dryer and 500L Vertical Tank CORMAK LUFT 1000 VSD+PM 950L/min 7.5kW

Set including the LUFT 1000 VSD+PM screw compressor, a vertical compressed air receiver with fittings with a capacity of 500 L and an IZBERG N10S refrigerated dryer. The CORMAK LUFT series screw compressor features modern pneumatic solutions combined with high-quality materials and ...More

Screw Compressor with Inverter, IZBERG N75S Dryer and 500L Vertical Tank CORMAK THEOR 75 55kW

Set including the THEOR 75 INVERTER screw compressor equipped with an inverter by CORMAK , a vertical compressed air receiver with a capacity of 500L , and an air dryer IZBERG N75S . The CORMAK THEOR series screw compressors combine the latest pneumatic technologies with high-quality ...More

Screw Compressor with IZBERG N10S Dryer and 1000L Vertical Tank CORMAK LUFT 1000 950L/min 7.5kW

A set including the LUFT 1000 screw compressor, a vertical compressed-air receiver with fittings with a capacity of 1000L and the IZBERG N10S air dryer. The CORMAK LUFT series screw compressor offers state-of-the-art pneumatic solutions combined with high-quality materials and components. ...More

Screw Compressor with IZBERG N10S Dryer and 500L Vertical Tank CORMAK LUFT 700 650L/min 5.5kW

The set includes a LUFT 700 screw compressor, a vertical air receiver with fittings for compressed air with a capacity of 500 L , and an IZBERG N10S dryer. The CORMAK LUFT series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low ...More

The set includes the LUFT 1000 screw compressor with inverter , a 270-litre vertical air tank equipped with fittings for compressed air systems, and the IZBERG N10S refrigeration air dryer . The CORMAK LUFT series of screw compressors represents the most advanced pneumatic solutions combined ...More

Screw Compressor with IZBERG N10S Dryer and 270L Vertical Tank CORMAK LUFT 1000 950L/min 7.5kW

The set includes the LUFT 1000 screw compressor, a vertical 270 L air receiver with fittings, and the IZBERG N10S air dryer. The CORMAK LUFT Series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low operating costs, ease of use, ...More

Screw Compressor with N10S Dryer and 200L Vertical Tank CORMAK LUFT 700 VSD+PM 650L/min 5.5kW

This complete set includes the CORMAK LUFT 700 VSD+PM screw air compressor , a vertical 200 L air receiver with fittings, and the IZBERG N10S refrigerated air dryer . The LUFT series from the Polish brand CORMAK represents cutting-edge pneumatic technology combined with high-quality ...More