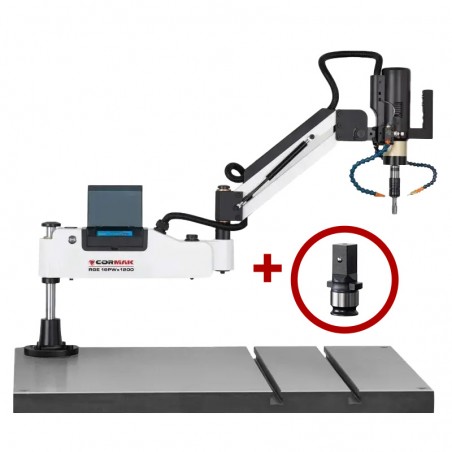

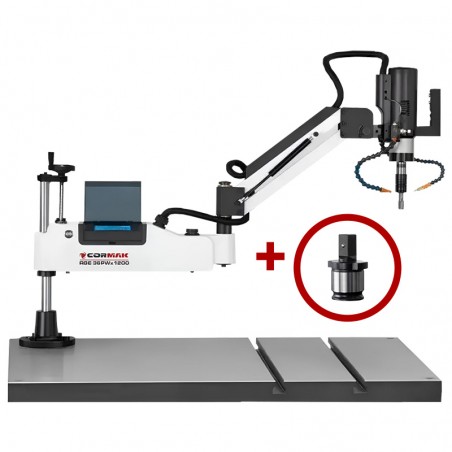

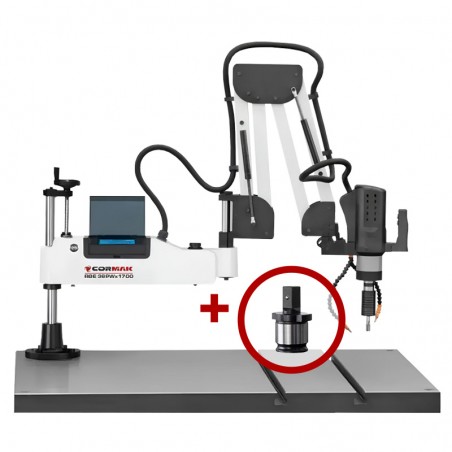

Description of the CORMAK RGE30PW Electric Tapping Machine

The CORMAK RGE30PW Electric Tapping Machine is an innovative industrial tool that revolutionises the way threads are cut in different materials. Incorporating the latest technology, the RGE30PW enables fast, precise, and efficient threading operations for both large-scale production and small workshops. Thanks to its servomotor and modern control system, the machine speeds up the entire threading process while providing exceptional reliability and thread quality, making it an indispensable tool in any production environment.

Main Advantages of the CORMAK RGE30PW Electric Tapping Machine

- High performance: Equipped with a powerful servomotor, the CORMAK RGE30PW ensures fast and accurate threading, significantly reducing operation time compared to traditional manual methods.

- Precision threading: The use of a rotating arm and easily adjustable parameters such as spindle speed, threading direction, and thread depth guarantees excellent thread quality with a perfect 90° angle.

- Versatile applications: The machine handles a wide range of materials, including steel, stainless steel, aluminium, and non-ferrous metals, making it ideal for diverse industrial sectors.

- Intuitive control panel: The modern touch control panel allows easy programming of work parameters and is available in English for straightforward operation.

- Rotating tapping arm: Enables precise threading at any angle, significantly improving flexibility in different applications.

- Cooling and chip removal system: The integrated micro-lubrication system cools the tools, extending their lifespan, while the blower efficiently removes chips, improving visibility during operation.

Construction and Technology

The CORMAK RGE30PW electric tapping machine is designed for efficiency, precision, and durability. Its solid structure ensures long-term, trouble-free operation, even under intensive use. Key components such as the tapping arm are engineered to provide outstanding stability and precision during threading operations.

The servomotor delivers high torque, ensuring smooth and accurate threading performance. With an integrated cooling and chip removal system, the CORMAK RGE30PW operates continuously without overheating or contamination of processed parts. The micro-lubrication unit and chip blower enhance both comfort and efficiency by ensuring clear visibility and optimal tool cooling.

Precision and Work Efficiency

The CORMAK RGE30PW guarantees exceptional precision through advanced servomotor technology and an intelligent control system. Its rotating arm with a wide range of motion enables threading at any angle, increasing versatility. Adjustable spindle speed and thread depth provide full process control, ensuring perfect thread quality across various materials.

This tapping machine also offers high productivity, significantly reducing threading time compared to manual techniques. Its efficiency makes the CORMAK RGE30PW the ideal solution for serial production and demanding industrial applications where time and quality are critical factors.

Applications of the CORMAK RGE30PW Tapping Machine

The CORMAK RGE30PW electric tapping machine is widely used in many industries, including:

- Mass production: Threading large quantities of components in a short time.

- Metal industry: Ideal for threading parts made of steel, stainless steel, aluminium, and non-ferrous metals.

- Automotive industry: Used for producing precision automotive components.

- Precision manufacturing: Perfect for fine-threading operations in electronics and precision machinery components.

- Craft workshops: Excellent for small-batch and prototype production.

Standard Equipment of the CORMAK RGE30PW Tapping Machine

- Touch control panel: Enables easy programming of threading parameters such as spindle speed, direction, and depth.

- Rotating tapping arm: Allows thread cutting at any angle.

- Tap holders with overload clutches: Protect the device against excessive loads, ensuring long-term durability.

- Micro-lubrication system: Provides constant tool cooling with minimal coolant consumption.

- Chip blower: Removes chips for improved visibility during threading.

Technical Specifications of the CORMAK RGE30PW Tapping Machine

| Power |

1.2kW |

| Power supply |

230V |

| Weight |

50kg |

| Max. arm reach |

1200mm |

| Max. spindle speed |

200rpm |

Included: Tap holders ranging from M5 to M30

*Machine supplied without worktable, vice, or taps.

Add the CORMAK RGE30PW tapping machine to your basket and boost your threading efficiency. Experience precision and cutting-edge technology for perfect threads in every industrial application.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.