The basket is empty.

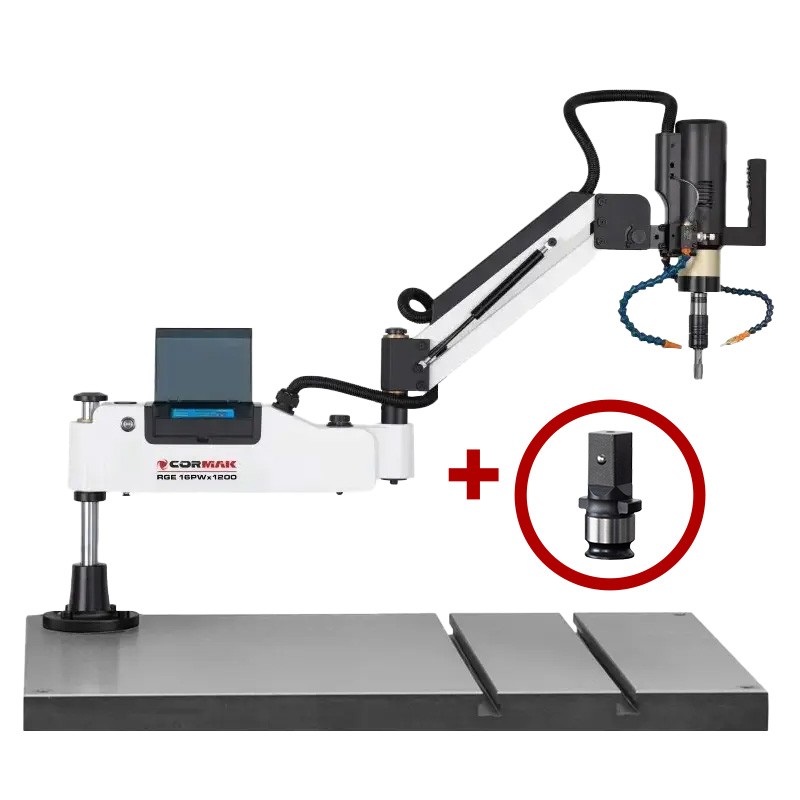

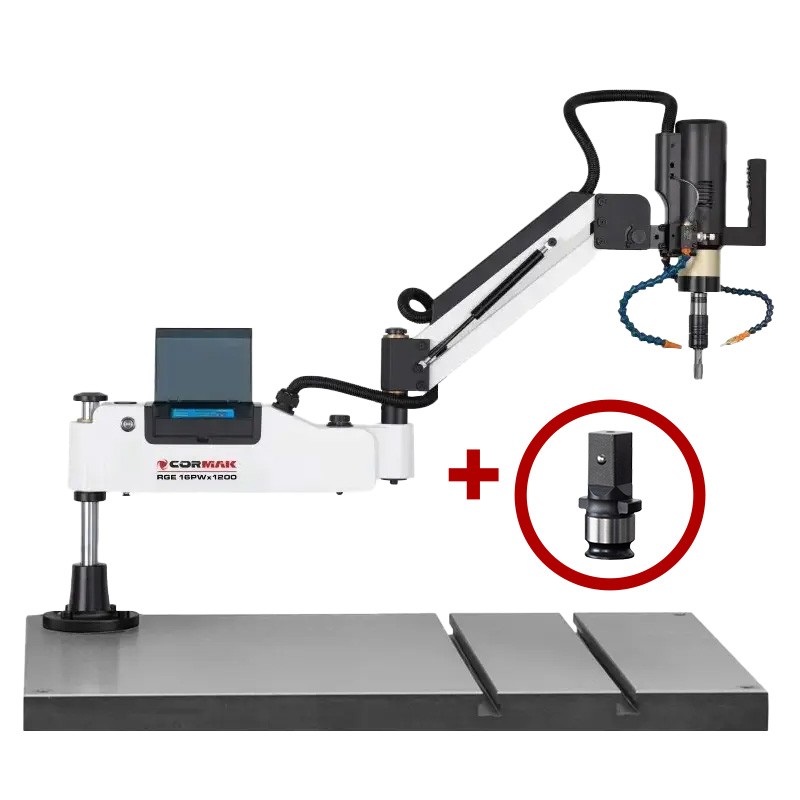

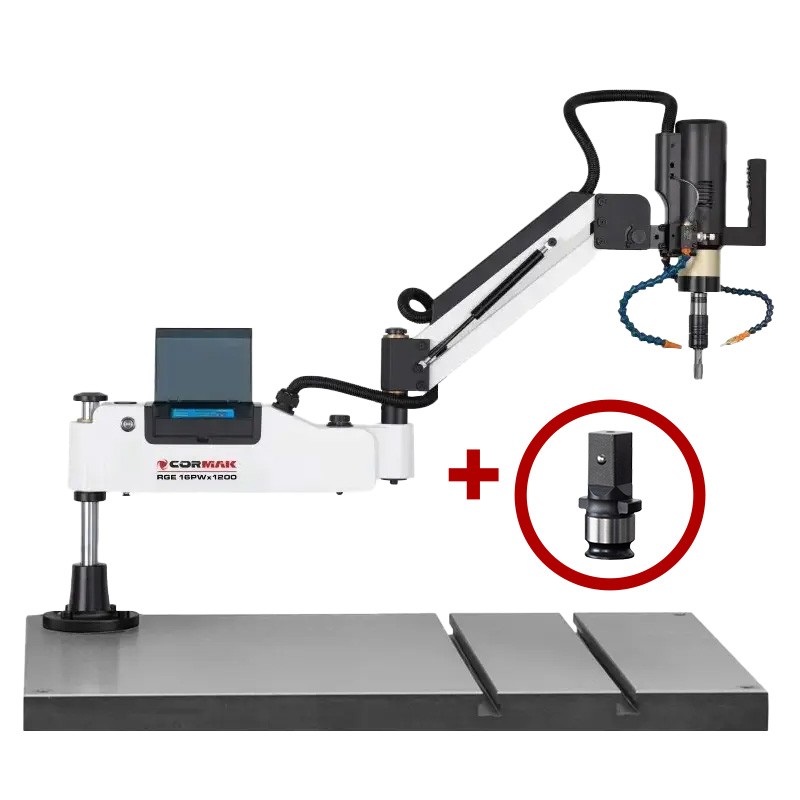

The electric tapping machine is a compact and efficient device designed for thread cutting, suitable for both large production facilities and small workshops. Equipped with a high-torque servomotor and swivel head, it enables fast and precise threading operations. The integrated cooling system with air blow ensures optimal visibility of the drilled hole. The tapping arm offers two operating modes – automatic and manual – as well as a tightening function.

The CORMAK RGE16PW Electric Tapping Machine is an advanced device designed for threading a wide range of materials, suitable for both industrial and workshop applications. Thanks to its innovative technology and robust design, the CORMAK RGE16PW significantly reduces threading time while ensuring high precision and efficiency, making it an indispensable tool in every production environment. The unit combines speed, accuracy, and reliability, allowing easy thread cutting at various angles with full process control.

The CORMAK RGE16PW tapping machine is designed for intensive operation in demanding industrial conditions. Its structure is based on solid and precise components, ensuring long-lasting reliability and high performance. The central component of the unit is the tapping arm with a quick-release chuck that allows rapid tool exchange, increasing work efficiency.

The tapping arm is driven by a high-torque servomotor, enabling precise thread cutting. The rotating arm design provides flexibility, allowing threading at any angle, making the unit a versatile tool across many industries. Additionally, the tap holders feature adjustable overload clutches that protect the system from damage due to excessive load.

The entire structure of the CORMAK RGE16PW tapping machine is designed for ease of use and durability. The drive mechanism withstands heavy-duty operation, while the cooling system maintains consistent performance during long threading cycles.

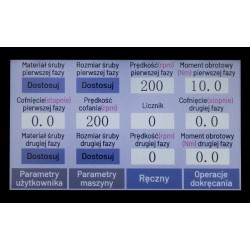

The threading process with the CORMAK RGE16PW ensures outstanding accuracy thanks to the servomotor technology that controls every movement of the tapping arm with great precision. The control system enables programming of key operational parameters such as:

These parameters enable the operator to adapt the process to specific production needs, increasing accuracy and efficiency. The CORMAK RGE16PW tapping machine provides quick and accurate thread cutting, reducing cycle times while enhancing product quality.

The CORMAK RGE16PW is suitable for a wide range of industrial uses, including:

This versatile tool is ideal for both mass production and high-precision individual operations. Its user-friendly control and programmable parameters make it suitable for a wide range of industries, from automotive to general metalworking.

| Power | 0.6kW |

| Power supply | 230V |

| Weight | 30kg |

| Max. arm reach | 1080mm |

| Max. spindle speed | 375rpm |

Included: Tap holders M3, M4, M5, M6-8, M10, M12, M13, M16

*Machine supplied without worktable, vice, or taps.

Purchasing the CORMAK RGE16PW Tapping Machine is an investment in precision, speed, and reliability. Discover how this modern electric tapping unit can enhance your workshop productivity. Add to basket and speed up your threading process today!

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Tapping Head Spindle Positioner 90° CORMAK GT12

The neodymium adapter for positioning the tapping arm spindle is a modern tool that enables precise alignment of the tapping unit at a perfect 90° angle to the workpiece. With the GT12 adjustable positioner, users can easily and accurately achieve the correct setting, ensuring superior thread quality and repeatability. ...More

Tapping Head Spindle Positioner 90° CORMAK GT12

The neodymium adapter for positioning the tapping arm spindle is a modern tool that enables precise alignment of the tapping unit at a perfect 90° angle to the workpiece. With the GT12 adjustable positioner, users can easily and accurately achieve the correct setting, ensuring superior thread quality and repeatability. ...More

Electric Tapping Machine CORMAK RGE36PWx1200 with Socket Adapter

The electric tapping machine is a versatile threading tool, ideal for both large factories and small workshops. Its compact design with a movable head and high-torque servomotor ensures powerful and reliable operation. The unit allows easy and quick tap mounting, adjustable threading angle, and ...More

Electric Tapping Machine CORMAK RGE30PW with Socket Adapter

The electric tapping machine is a versatile threading tool, ideal for both large factories and small workshops. Its compact design with a movable head and high-torque servomotor ensures strong and reliable performance. The unit allows easy and fast tap mounting, adjustable threading angle, and ...More

Tapping Head Spindle Positioner 90° CORMAK GT24

The neodymium adapter for positioning tapping arm spindles is an innovative device that enables precise adjustment of the tapping unit at a perfect right angle to the workpiece. Using a 90° calibration system, the GT24 positioner allows users to easily and accurately achieve correct spindle alignment for professional thread cutting. ...More

Tracing Workbench for Tapping Machines CORMAK 900x600 mm

The tracing workbench dedicated to tapping machines is a solid and functional solution for professionals. It features mounting holes for a tapping arm and a ground tabletop with T-slots spaced at 152 mm. This high-quality table, measuring 900 mm x 600 mm x 780 mm, ensures stability, precision and ...More

Electric Tapping Machine CORMAK RGE36PWx1700

The CORMAK RGE36PWx1700 is a professional electric tapping machine designed for precise and efficient threading in both industrial plants and smaller workshops. Its robust construction, high-torque servomotor, and rotating head ensure smooth, powerful performance. Equipped with an oil dispenser, ...More

Tapping Collet Set M3, M4 with Adapter GT24–GT12

The Tapping Collet Set M3, M4 with Adapter GT24–GT12 is designed for use with CORMAK tapping arms and electric tapping machines. This professional accessory allows the use of smaller taps, ensuring precision, flexibility and safety during threading operations. ...More

Tracing Workbench for Tapping Machines CORMAK 800x500 mm

The tracing workbench dedicated to tapping machines is a solid and functional solution for professionals. It features a ground tabletop with T-slots spaced at 152 mm. This high-quality table, measuring 800 mm x 500 mm x 860 mm, offers stability, precision and mobility during threading operations. ...More

2024-12-24

Gwintownica m16

Jakość znacznie lepsza niż w gwintownicach dostępnych na rynku w podobnych cenach. Mam kilka maszyn z CORMAKA i z tej tez jestem bardzo zadowolony. Intuicyjne menu.