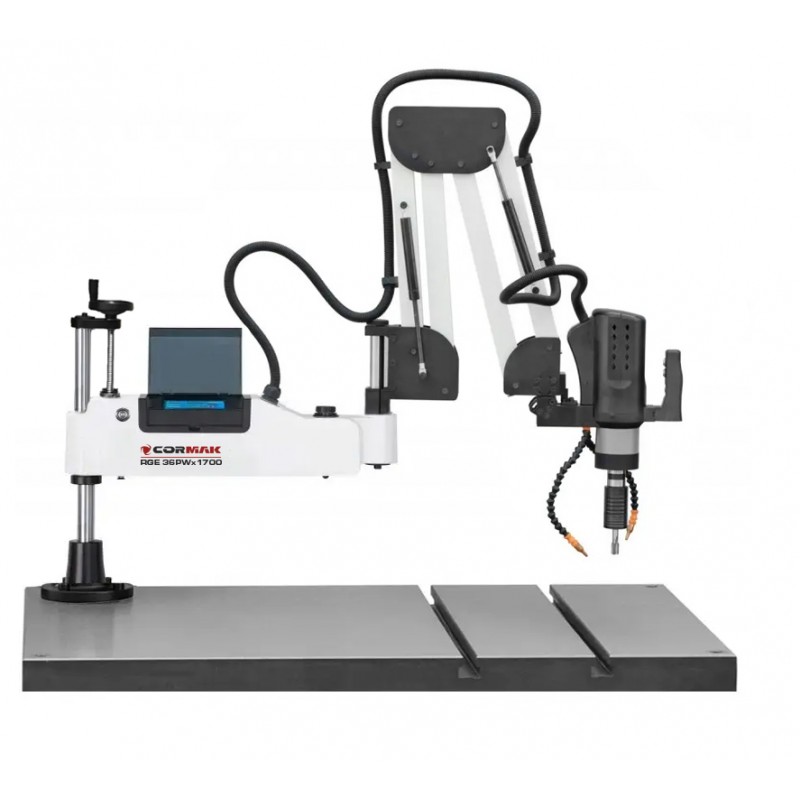

Description of the CORMAK RGE36PWx1700 Electric Tapping Machine

Electric Tapping Machine CORMAK RGE36PWx1700 is an advanced threading device ideal for large production facilities and smaller workshops. It significantly shortens threading times, improving productivity and thread precision. Designed for reliability, ease of use and versatility, this machine offers consistent, high-quality results in a wide range of industrial applications.

Main Advantages of the CORMAK RGE36PWx1700 Electric Tapping Machine

- High precision and speed: The powerful servo drive and tapping arm provide fast and accurate threading, essential for serial production.

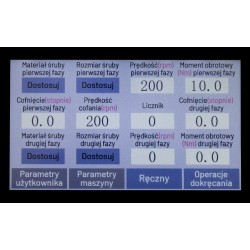

- Ease of use: A touchscreen control panel (available in English) allows quick adjustment of threading parameters such as speed, direction and depth.

- Flexibility: The tapping arm and rotating motor assembly enable threading at different angles, ensuring high versatility for various applications.

- Efficient cooling: The micro-spraying system cools the tools with minimal lubricant use, extending their lifespan and reducing material loss.

- Comprehensive equipment: The integrated chip-blowing system keeps the workspace clear for better visibility and efficiency during threading.

Construction and Technology of the CORMAK RGE36PWx1700 Tapping Machine

The CORMAK RGE36PWx1700 features a solid structure designed for precise and efficient operation in industrial environments. Powered by a servo motor, it delivers smooth, reliable performance and precise control of all threading parameters. The combination of the tapping arm and rotating motor assembly allows threading in different materials, including steel, stainless steel, aluminium and non-ferrous metals.

The tapping arm includes a quick-change holder for fast tap replacement. Adjustable overload clutches in the tap holders protect the tools from damage during operation and allow fine control of torque, ensuring accuracy and repeatability.

Precision and Work Efficiency of the CORMAK RGE36PWx1700

The high performance of the CORMAK RGE36PWx1700 results from advanced technology and durable construction. Its servo drive and rotating arm deliver accurate threading at speed, while adjustable rotation and depth settings make it suitable for threads with various parameters. The integrated micro-spraying system efficiently cools tools, enhancing performance and service life.

Applications of the CORMAK RGE36PWx1700 Tapping Machine

The CORMAK RGE36PWx1700 is suitable for many industrial sectors, including:

- Serial production: High-volume threading in minimal time.

- Metal industry: Perfect for threading components made of steel, stainless steel, aluminium and non-ferrous metals.

- Automotive industry: Used in precision automotive parts manufacturing.

- Precision engineering: Ideal for threading components in electronics and precision machinery.

- Craft workshops: Suitable for small-batch production and prototypes.

Standard Equipment of the CORMAK RGE36PWx1700 Tapping Machine

- Touch control panel: Enables easy programming of parameters such as spindle speed, direction and thread depth.

- Rotating tapping arm: Allows threading at any angle.

- Tap holders with overload clutches: Protect the machine from overload and ensure long service life.

- Micro-spraying system: Provides continuous tool cooling with minimal coolant use.

- Chip blower: Efficiently removes swarf for better visibility during threading.

Technical Specifications of the CORMAK RGE36PWx1700 Tapping Machine

| Power |

2kW |

| Power supply |

230V |

| Weight |

56kg |

| Maximum arm reach |

1,700mm |

| Maximum rotation speed |

125rpm |

Included: Tap holders for M5–M36.

*The machine is supplied without worktable, vice or taps.

2024-12-24

Ramię CORMAK

Mocna i idiotoodporna, Sama dobierze odpowiednią prędkość gwintowania do wielkości gwintu. Dobra maszyna.