- Reduced price

The basket is empty.

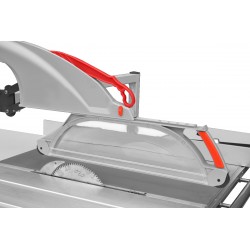

Sliding Panelsaw CORMAK MJ45-KB4 with Scoring Unit and Pneumatic Clamp is a solid, industrial sliding panelsaw designed for precise cutting of MDF, HDF, ABS, PVC, solid wood and other wood-based materials. This panelsaw allows for accurate cutting parameter adjustment, ensuring high quality and repeatability in small and medium-sized joinery workshops.

Sliding Panelsaw CORMAK MJ45-KB4 is an advanced panelsaw featuring a scoring unit and dual-zone pneumatic clamp, designed for intensive use in woodworking and panel processing plants. Its precise cutting units, stable construction and high ergonomics make this model a reliable solution for cutting furniture boards, MDF, HDF, plywood and coated materials.

Panelsaw CORMAK MJ45-KB4 features a robust, welded steel frame that provides high rigidity to the entire structure. The sliding table runs on hardened bars, ensuring backlash-free and precise motion—crucial when processing large boards. The main blade Ø350 mm and scoring blade Ø125 mm run at high speeds, ensuring efficient and clean cutting of laminated surfaces.

The pneumatic clamping system based on four cylinders ensures firm adhesion of the material to the work surface, significantly improving cutting accuracy and eliminating the risk of shifting, particularly when working with thin or large components.

Sliding panelsaw CORMAK MJ45-KB4 enables adjustment of cutting depth and angle across a wide range. Two spindle speed settings (4000 / 6000 rpm) allow matching the cutting speed to the material. The pneumatic clamp greatly improves repeatability and cutting safety. This makes it ideal for precise furniture manufacturing, joinery and architectural woodwork production.

The machine is used in:

Its design and parameters make the sliding panelsaw with scoring unit and pneumatic clamp a professional tool for operators requiring reliability and precision.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training — please contact our consultant for more details.

| Technical specifications | |

| Table dimensions | 990 x 575 mm |

| Sliding table length | 3200 mm |

| Cutting width at fence | 1250 mm |

| Crosscut length with fence | 3100 mm |

| Blade tilt | 0° - 45° |

| Main blade diameter | Ø350 mm |

| Main blade bore | Ø30 mm |

| Cutting height | 0–105 mm |

| Cutting height at 45° | 0–80 mm |

| Main spindle speed | 4000 / 6000 rpm |

| Scoring blade diameter | Ø125 mm |

| Scoring blade bore | Ø20 mm |

| Scoring blade speed | 8000 rpm |

| Main motor power S1/S6 | 5.5 kW / 9 HP |

| Scoring motor power S1/S6 | 0.75 kW / 1.2 HP |

| Dust extraction outlet (below table) | 100 mm |

| Dust extraction outlet (blade guard) | 80 mm |

| Machine weight | 680 kg |

Note: the machine is sold without saw blades.

Invest in proven technology – choose the CORMAK MJ45-KB4 Sliding Panelsaw with Scoring Unit and Pneumatic Clamp to increase precision and efficiency in your production facility.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Wood Dust and Chip Extractor CORMAK FM300SA

CORMAK FM300SA is a high-performance wood dust and chip extractor designed for continuous operation in industrial, joinery and furniture workshops. Featuring a 2.2 kW motor, WhirlWind multi-blade impeller and four large filter bags (total 220 L), this industrial dust collector ensures ...More

Wood Dust and Chip Extractor CORMAK FM500

CORMAK FM500 is an industrial wood dust extractor designed for heavy-duty use in large woodworking, furniture and production facilities. With an impressive extraction capacity of 5,000 m³/h, a stable steel structure and the ability to connect up to four machines simultaneously, the FM500 ...More

Circular Saw Blade Freud 300x3.2x30 Z96

High-quality Freud circular saw blade with a diameter of 300 mm designed for panel saws. Ideal for cutting double-sided laminated boards using a scoring blade, especially melamine-coated boards. It ensures excellent cutting quality and long service life. ...More

Suction and Pressure Hose Ø100 mm 10 m

Suction and discharge hose with an internal diameter of 100 mm and a length of 10 metres . Designed for applications requiring both suction and pressure transport of gaseous or liquid materials — ideal for dust extraction systems, chip and sawdust collectors, and for air or liquid transfer. ...More

Suction and Pressure Hose Ø100 mm – 6 m

Suction and Pressure Hose Ø100 mm (6 metres) designed for industrial applications requiring both suction and discharge of gaseous or liquid materials. Perfect for dust extraction systems, sawdust and chip removal, as well as for air and liquid transport in production and workshop environments. ...More

Suction and Pressure Hose Ø100 mm – 3 m

Suction and Pressure Hose Ø100 mm (3 metres) designed for industrial applications requiring both suction and discharge of gaseous or liquid materials. Ideal for dust extraction systems, sawdust and chip removal, as well as for air and liquid transport in production environments. ...More

Suction and Pressure Hose Ø80 mm – 6 m

Suction and Pressure Hose Ø80 mm (6 metres) designed for use in systems requiring both suction and discharge of gaseous or liquid materials. Perfect for dust extraction, chip and sawdust removal, as well as for transporting air and liquids in workshops and production environments. ...More

Wood Dust and Chip Extractor CORMAK FM350 with Fine Dust Filters

CORMAK FM350 with fine dust filters is a professional industrial wood dust and chip extractor designed for high-efficiency dust removal in woodworking plants. Its 3.8 kW three-phase motor, robust steel impeller and advanced filtration system ensure effective extraction of chips, sawdust and ...More

Wood Dust and Chip Extractor CORMAK FM300SA with Fine Dust Filters

CORMAK FM300SA with fine dust filters is a high-performance wood dust and chip extractor designed for continuous operation in woodworking and furniture workshops. Featuring a 2.2 kW motor, four 220 L filter bags and fine dust filtration up to 2 µm, it ensures clean air, high suction efficiency ...More

Wood Dust and Chip Extractor CORMAK FM350

CORMAK FM350 is a powerful industrial wood dust and chip extractor designed for heavy-duty use in professional woodworking environments. With an impressive suction capacity of 4860 m³/h, a 3.8 kW motor and six large collection bags (3 × 200 L), it ensures clean, safe and efficient dust ...More

Wood Dust and Chip Extractor CORMAK FM500 with Dust Filters

CORMAK FM500 Wood Dust Extractor with Dust Filters is a high-performance machine designed for efficient removal of chips, sawdust and fine dust generated during woodworking. Equipped with a third-stage filter system capable of capturing particles as small as 2 microns, it significantly improves ...More

Każdy szczegół cięcia jest idealnie dopracowany, co znacząco podnosi jakość produktu.

Ten model spełnia wszystkie moje oczekiwania – polecam z czystym sumieniem.

Każde cięcie wykonane jest z wyjątkową dokładnością, nawet przy największych arkuszach.

Solidna budowa i wysokiej jakości materiały zapewniają długą żywotność urządzenia.

Stabilna konstrukcja gwarantuje, że maszyna nie ulega drganiom nawet przy intensywnej pracy.

Nowoczesne technologie zastosowane w maszynie podnoszą efektywność i komfort pracy.

Model ten charakteryzuje się wysoką wydajnością i niskim zużyciem energii.

Duży stół formatowy umożliwia obróbkę bardzo dużych arkuszy materiału, co znacznie podnosi efektywność.

Model spełnia wymagania nawet najbardziej zaawansowanych zakładów stolarskich.

Płynna regulacja wysokości tarczy pozwala na idealne dopasowanie do materiału.

Maszyna pracuje niezwykle wydajnie, co pozwala na szybkie tempo produkcji.

To sprzęt, na który zawsze można liczyć – niezawodny i precyzyjny.

To urządzenie to must-have w każdym dużym zakładzie stolarskim.

Idealny model dla dużych zakładów, gdzie liczy się wydajność i precyzja cięcia.

To urządzenie działa bez zarzutu nawet przy dużym obciążeniu produkcyjnym.

Wyniki cięcia są imponujące, co wpływa na jakość finalnych produktów.

Ergonomiczny design sprawia, że operator pracuje komfortowo nawet przez wiele godzin.

Każde cięcie jest wykonywane z dokładnością, która zadowoli nawet wymagających klientów.

Intuicyjny interfejs i prosta konserwacja czynią pracę z tą maszyną niezwykle wygodną.

2024-12-21

Profesjonalny standard

Model ten ustanawia wysoki standard jakości w przemyśle stolarskim.