The basket is empty.

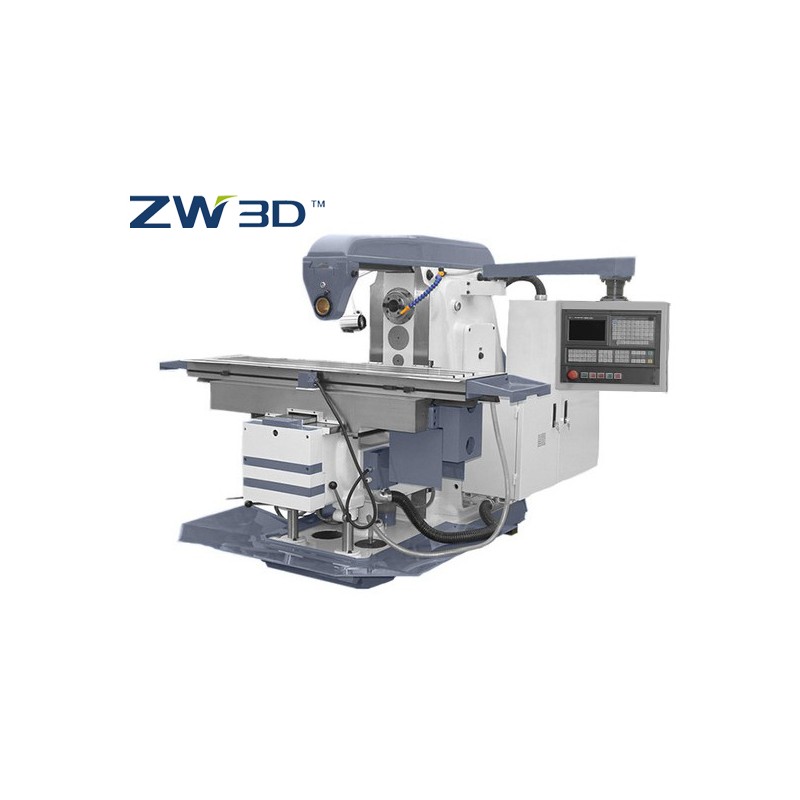

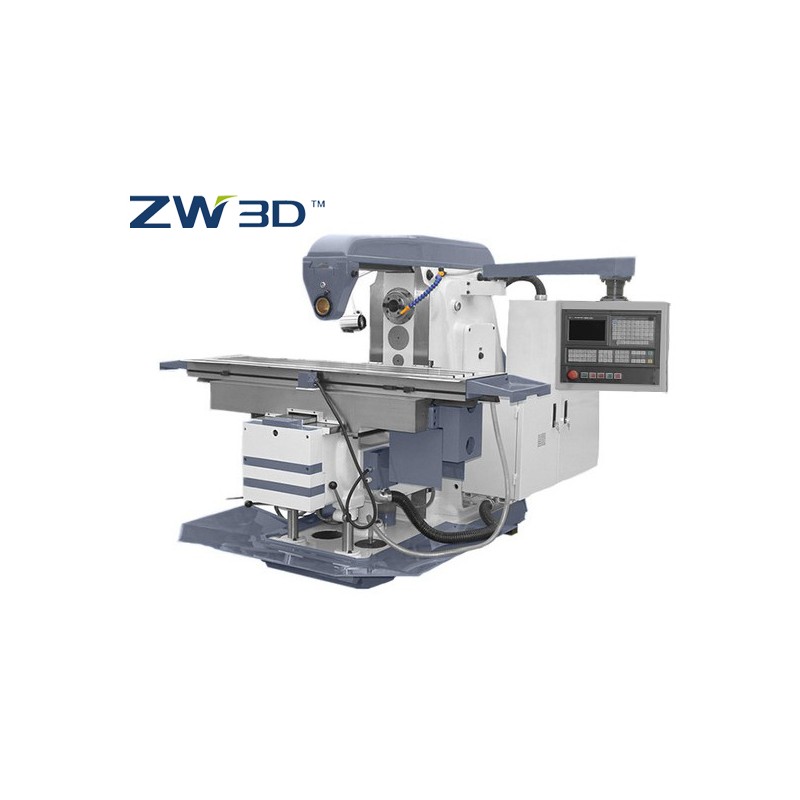

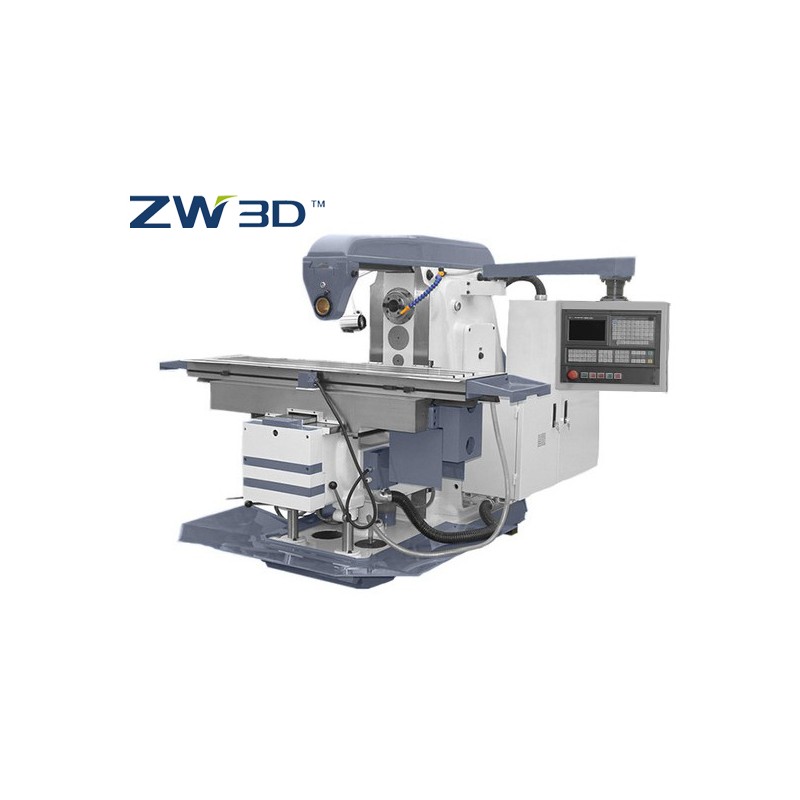

The CORMAK VM1700 CNC Milling Machine is designed for machining individual parts and small series. Its heavy cast-iron frame and large worktable provide exceptional stability and flexibility in metal machining. Fast and simple CNC programming allows for rapid changeovers, making this machine ideal for workshops and production facilities requiring precision and efficiency.

The CORMAK VM1700 CNC Milling Machine is an advanced CNC machine tool designed for precision metal machining in demanding industrial applications. Featuring a rigid construction, modern CNC control and a spacious working area, this metal milling centre ensures high performance, flexibility and durability.

The CORMAK VM1700 combines solid design with advanced technology, offering significant benefits for industrial users:

The CORMAK VM1700 CNC Machining Centre is an ideal choice for production facilities seeking precision, performance and versatility in metal machining.

The CORMAK VM1700 is built for durability, accuracy and user comfort. Its main design features include:

The rigid cast-iron structure provides outstanding stiffness and vibration damping. The 1700 × 400 mm table with T-slots enables secure clamping of workpieces of different shapes and sizes.

The ISO 50 spindle, operating at 30–1500 rpm and driven by an 11 kW motor, ensures powerful cutting performance. Optional through-spindle cooling increases efficiency and extends tool life.

Linear guides and precision servo drives ensure smooth movement in X, Y and Z axes (920 × 380 × 330 mm), minimising positioning errors and improving dynamic accuracy.

Advanced CNC systems (standard GSK, optional Siemens 828D or Fanuc) offer precise control, simplified programming and CAD/CAM integration for complex machining projects.

The CORMAK VM1700 ensures exceptional accuracy and productivity through its robust build and modern CNC control. The 30–1500 rpm spindle range and high-speed feed system enable optimal toolpath planning, shorter cycles and improved output. Its 11 kW motor and rigid frame make it ideal for both series and single-part production.

The CORMAK VM1700 Metalworking Centre is suitable for demanding sectors such as:

With its advanced configuration options and wide working area, this CNC machining centre is the perfect solution for medium-sized production facilities.

The CORMAK VM1700 is available with professional CNC systems from leading manufacturers — GSK, Siemens and Fanuc — ensuring precision, reliability and ease of use.

Choose the CNC control that best suits your needs to maximise productivity and machining accuracy.

| Worktable size | 1700 × 400 mm |

| Table travel (X/Y/Z) | 920 × 380 × 330 mm |

| Spindle taper | ISO 50 |

| Spindle speed | 30–1500 rpm |

| Motor power | 11 kW |

| Machine dimensions | 2310 × 2200 × 2400 mm |

| Machine weight | 4250 kg |

*The quoted price refers to the machine only and excludes optional/additional equipment, installation, transport and training — please contact our consultant for more details.

As an experienced CNC machine manufacturer, CORMAK has been supplying reliable industrial solutions for over 20 years. Our CNC machines meet European safety standards, are CE certified and supported by professional service. With a warehouse area exceeding 15,000 m² and a team of experts, we provide full technical support and consultation.

By choosing CORMAK CNC milling machines, you invest in precision, reliability and long-term production efficiency.

Increase your production efficiency and accuracy with the CORMAK VM1700. Contact our team for detailed information, an individual quote or a demonstration. Contact us!

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CNC Milling Machine CORMAK VM1370

The CORMAK VM1370 CNC Milling Machine is an industrial-grade universal milling machine designed for heavy-duty applications, workshops, toolrooms and maintenance departments. Equipped with a horizontal spindle and a swivelling vertical head, it provides excellent flexibility in machining. The ...More

CNC Milling Machine CORMAK VM1320

The CORMAK VM1320 CNC Milling Machine is designed for machining individual parts and small series. Its heavy cast-iron base and large worktable provide excellent stability and flexibility, enabling precise metal machining even for small batches. The user-friendly CNC interface allows fast and ...More

CNC Milling Machine CORMAK MILL 854

The CNC milling machine is based on a solid construction, designed for precise metal machining with full numerical control. The machine is equipped with axis drives and a modern CNC controller that allows generating, editing, and executing machining programs (G-code). Thanks to its rigid structure ...More

CNC Milling Machine CORMAK MILL 1500++ with Swivelling Head

CNC Milling Machine CORMAK MILL 1500++ is an advanced CNC machine designed for precise metalworking in demanding industrial environments. With its robust construction, modern CNC control, and large working area, this metal machining centre ensures reliability, high efficiency, and versatility. ...More

CNC Milling Machine CORMAK MILL 1636

Industrial universal milling machine with CNC control designed for heavy industry and precision tooling. Equipped with a horizontal spindle and swivelling vertical head, the CNC Milling Machine CORMAK MILL 1636 is ideal for toolrooms, workshops, and maintenance departments. The 1600x360 mm ...More

CNC Milling Machine CORMAK MILL 2050

High-quality CNC milling machine with a robust construction. A large worktable allows machining of heavy parts up to 1,800 kg . Servo motors and precision ball screws are used in all axes for smooth and accurate movement, ensuring durability and excellent machining precision. ...More

Write your review

* Required fields

I accept privacy policy rules