How to Choose the Right Dust Extractor Capacity for Your Workshop

How to Choose the Right Dust Extractor Capacity for Your Workshop | Blog - CORMAK

How to Choose the Right Dust Extractor Capacity for Your Workshop

Choosing the right dust extractor is essential for clean, safe, and efficient woodworking. An undersized extractor won’t handle dust properly, while an oversized one may waste energy and create unnecessary noise. Here’s how to match extractor performance to your production needs.

1. Identify your machines and waste volume

Each machine produces a different amount of dust. Table saws and planers generate much more waste than routers or drills. Estimate the total airflow required for all machines that may operate simultaneously.

2. Check duct diameter

The extractor’s performance must match the duct size — the larger the diameter, the higher the airflow required. Approximate guidelines:

- Ø100 mm – around 700–900 m³/h

- Ø120 mm – around 900–1200 m³/h

- Ø150 mm – around 1300–1800 m³/h

3. Choose proper motor power

For a single machine, 1.1–2.2 kW is usually enough. Multi-station workshops should use 3–7.5 kW units or central extraction systems with a splitter.

4. Consider duct length and layout

Longer ducting and multiple bends increase airflow resistance. Add approximately 10–20% extra capacity for every 5 meters of ducting or each bend in the system.

5. Filtration and safety

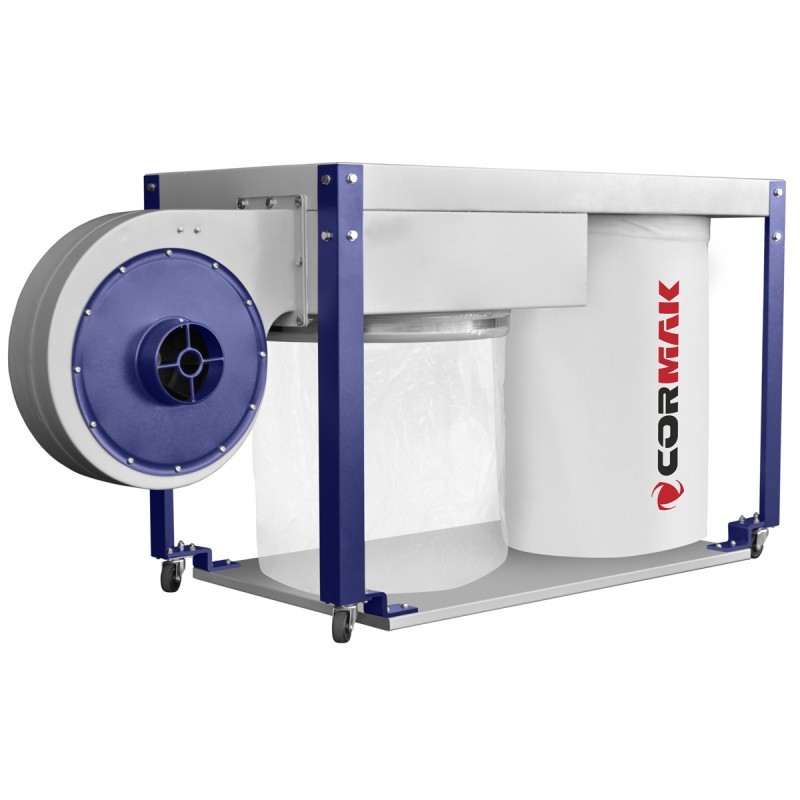

Modern units like CORMAK DC models feature fabric or cartridge filters that effectively capture fine dust, improving air quality and extending machine life.

Conclusion

The right dust extractor capacity depends on the number of machines, duct diameter, and installation layout. A properly designed system removes dust efficiently, quietly, and economically. CORMAK dust extractors offer a wide range of solutions — from compact workshop models to industrial units exceeding 5000 m³/h.