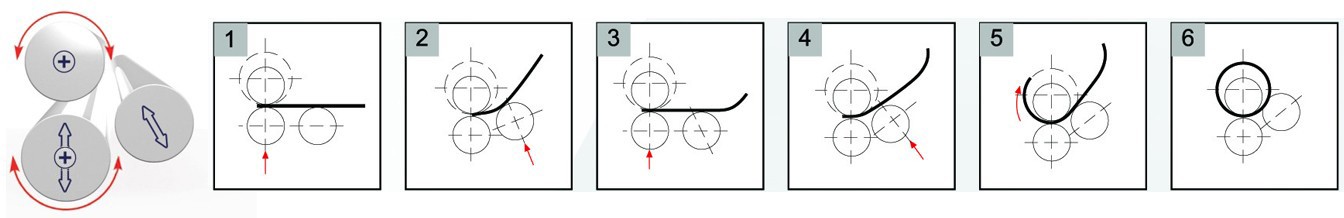

The professional three-roller machine RM-1270/90 with an asymmetric arrangement of rolls is used to produce cylindrical and conical forms of various diameters. This model is designed for bending sheets with a thickness of up to 2.5 mm and a width of up to 1270 mm. The diameter of the upper roll is 90 mm. The mechanical rolling machines of the RM series are perfect for workshops, as well as for craft and medium-series production.

|

ROLLING MILL MODEL |

1270/90 |

|

CYLINDER LENGTH (mm) |

1270 |

|

CYLINDER DIAMETER (mm) |

90 |

|

MATERIAL THICKNESS (mm) |

2.5 |

| BENDING SPEED (m/min.) | 6 |

| MAIN MOTOR POWER (kW) | 1.1 |

|

LENGTH (mm) |

1850 |

| DEPTH (mm) | 700 |

| HEIGHT (mm) | 1200 |

|

WEIGHT APPROX. (kg) |

520 |

NOTE: Standard equipment ratings are based on metals with a cold yield strength of 260 N/mm 2 .

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

The professional three-roller machine RM-1270/90 with an asymmetric arrangement of rolls is used to produce cylindrical and conical forms of various diameters. This model is designed for bending sheets with a thickness of up to 2.5 mm and a width of up to 1270 mm. The diameter of the upper roll is 90 mm. The mechanical rolling machines of the RM series are perfect for workshops, as well as for craft and medium-series production.