-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

New Generation Laser Cleaning Machine

The new generation surface cleaning device ensures excellent performance while remaining easy to install and operate. This makes it ideal for a variety of applications, from industrial to maintenance use. Removing paint, oils, dirt, rust, deposits, or resins is easier than ever before, all thanks to advanced laser technology. Control interface available in English.

Environmentally Friendly

One of the main advantages of laser cleaning is its environmentally friendly operation. The absence of chemical agents means the process does not cause chemical corrosion, which significantly reduces the impact on ecosystems.

Precision and No Material Damage

Thanks to precise control systems, the device can efficiently clean various surfaces such as aluminium, stainless steel, and structural steel without the risk of damage. Adjustable beam power and shape allow fine-tuning of cleaning parameters to suit each surface and task.

As a result, the fibre laser cleaning machine becomes an indispensable tool in many industries, delivering excellent cleaning performance with minimal risk of surface damage. Due to its versatility and efficiency, it has become an integral part of production and maintenance processes, contributing both to greater productivity and environmental protection.

Technical Parameters

| Laser power |

1500W |

| Total power |

4kW |

| Power supply |

230V |

| Scanning frequency range |

10–100Hz |

| Fibre cable length |

7m |

| Pulse frequency |

5–100kHz |

| Weight |

180kg |

| Dimensions |

700 × 1200 × 1250mm |

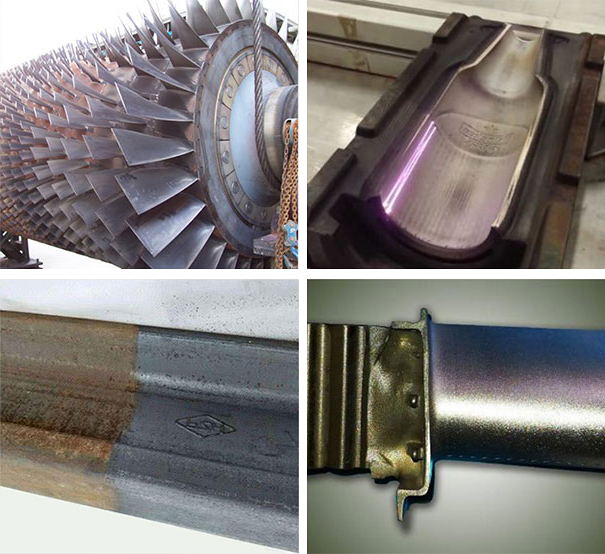

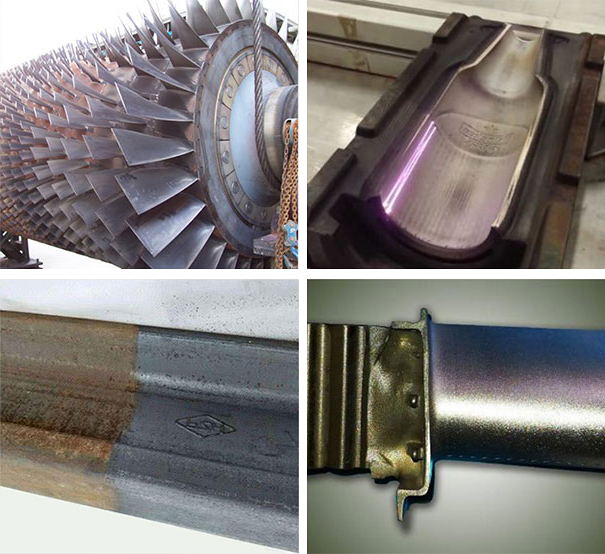

Laser Cleaning Applications

- Paint removal

- Weld cleaning

- Rust removal

- Laser degreasing

- Mould degreasing

- Oxide layer removal

- Stone surface restoration

- Screw drive cleaning

- Paint removal from castings

- Rust removal from turbine blades

- Rust removal from gear wheels

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

3 other products in the same category:

Write your review

* Required fields

I accept privacy policy rules