The basket is empty.

The industrial high-performance CNC lathe CK7150LT12x750 with a slant bed features a compact design, easy operation and maintenance. It is designed for machining non-ferrous metals, ferrous metals and non-metals. The lathe is capable of turning cylindrical, conical, and face surfaces, boring, grooving, threading, and spherical turning, making it suitable for use across mechanical, automotive, and light industries, as well as in the production of electrical components — both for mass and single-piece production. The 12-position turret head is equipped with driven tools.

The CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools is an advanced slant-bed CNC lathe designed for precise machining of metal components in industrial environments. Equipped with driven tools, a 12-position turret, and Siemens Sinumerik 808D control, it offers reliability, high performance, and versatility in a compact form.

The CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools combines modern technology with a robust slant-bed construction, providing users with significant benefits in production processes. Its key advantages include:

The CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools is the perfect solution for production plants requiring a precise, multifunctional machine for both series and single-piece production.

The CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools is designed with durability, precision and ease of operation in mind. Key components include:

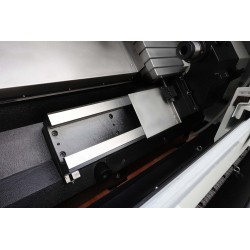

The slant bed provides high rigidity and effective chip evacuation, minimising vibration during machining. The maximum turning diameter over the bed is 500 mm, over the carriage 290 mm, and the maximum workpiece length 750 mm, allowing stable machining of small and medium-sized parts.

The spindle, with a bore of 52 mm and a maximum speed of 3000 rpm, powered by an 11 kW motor, ensures high cutting performance. The hydraulic 3-jaw chuck of 210 mm provides reliable clamping of workpieces.

Linear guideways and precise Siemens servo drives on the X/Z axes (travel 500/210 mm) ensure smooth movement and high dynamics, minimising positioning errors.

The standard Siemens Sinumerik 808D control (optionally Siemens 828D or Fanuc Oi-TF) with a USB port and RS-232 interface allows precise programming and easy integration with CAD/CAM systems. The control panel with IP65 protection rating ensures reliability under demanding workshop conditions.

The industrial lathe CORMAK CK7150X750 LT12 with Driven Tools offers exceptional precision thanks to a positioning accuracy of 0.001 mm and advanced CNC control. Driven tools and a 12-position turret enable complex operations such as milling and drilling in a single workpiece setup, reducing cycle times and increasing productivity. The 11 kW motor provides stable cutting performance even under heavy loads.

The CNC metal lathe CORMAK CK7150X750 LT12 with Driven Tools is used in demanding industries such as:

Thanks to driven tools and a compact design, the slant-bed CNC lathe is an excellent choice for production facilities with limited space that require a multifunctional machine.

The CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools offers professional CNC systems from renowned manufacturers such as Siemens and Fanuc, ensuring precision, efficiency and ease of use.

Sinumerik 808D is an economical CNC control system for metalworking CNC lathes, offering:

Sinumerik 828D is a professional CNC control system for industrial lathes, offering:

Fanuc Oi-TF is a reliable CNC control for CNC lathes, offering:

Select the CNC control best suited to your needs to enhance efficiency and precision in production processes!

| Turning diameter over bed | 500 mm |

| Turning diameter over carriage | 290 mm |

| Maximum workpiece length | 750 mm |

| Travel in X / Z axes | 500/210 mm |

| Spindle bore | 52 mm |

| Spindle speed | 3000 rpm |

| Chuck size | 210 |

| Spindle motor power | 11 kW |

| Positioning accuracy X / Z | 0.001 mm |

| Tool size | 20x20 mm |

| Number of tools | 12 |

| Tailstock sleeve diameter | 88 mm |

| Tailstock sleeve travel | 85 mm |

| Tailstock taper | MK5 |

| Dimensions L/W/H | 3700x1800x2100 mm |

| Weight | 4600 kg |

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

As an experienced CNC machine manufacturer, CORMAK has been providing reliable industrial solutions for over 20 years. Our metalworking CNC lathes meet the highest quality standards, hold European safety certifications, and are supported by professional service. With an extensive warehouse base of over 15,000 m² and a team of specialists, we offer full technical support and expert advice.

By choosing an industrial lathe from CORMAK, you invest in precision, reliability, and long-term production efficiency.

Increase your production efficiency and precision with the CNC Lathe CORMAK CK7150X750 LT12 with Driven Tools. Contact our team for detailed information, a personalised offer, or to schedule a machine demonstration.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Serrated Soft Jaws for Lathe Chucks

Serrated soft jaws are designed for precise clamping of workpieces in lathe chucks. Thanks to their soft material structure, they can be pre-machined to match a specific shape or diameter, ensuring perfect fit and repeatability in series production. The serrated connection provides stable seating ...More

Hard Top Jaws SGTm for Lathe Chucks

The SGTm hard top jaws are designed for secure and stable clamping of workpieces during machining. Made of hardened tool steel, they provide excellent wear resistance, making them ideal for demanding production environments. Perfect for applications requiring high clamping force and stability during turning. ...More

Tokarka sprawdza się świetnie przy obróbce dużych detali. Dzięki napędzanym narzędziom i transporterowi wiórów praca jest bardziej efektywna.

Sprawna maszyna, która pozwala na szybkie i dokładne wykonanie detali.

Tokarka bezawaryjna, idealna do intensywnej produkcji i precyzyjnej obróbki.

Tokarka CNC CK7150 LT 12x750 jest świetnym rozwiązaniem do obróbki detali. Dodatkowy transporter wiórów i napędzane narzędzia poprawiają efektywność pracy.

Maszyna o bardzo wysokiej jakości wykonania, niezawodna i wydajna.

Tokarka doskonale sprawdza się w dużych produkcjach seryjnych. Napędzane narzędzia i transporter wiórów umożliwiają szybkie i efektywne cięcie.

Bardzo precyzyjna maszyna, idealna do obróbki skomplikowanych detali.

Doskonała maszyna do produkcji detali wymagających precyzji. Napędzane narzędzia i odbiór detali z transporterem wiórów to świetne rozwiązanie w produkcji seryjnej.

Maszyna działa stabilnie i jest bardzo wydajna, co pozwala na szybszą produkcję.

Tokarka sprawdza się doskonale w intensywnej produkcji. Napędzane narzędzia i transporter wiórów to duża zaleta, która usprawnia cały proces.

Maszyna solidna, bezawaryjna, doskonała w produkcji seryjnej.

Tokarka CNC CK7150 LT 12x750 to maszyna, która charakteryzuje się dużą stabilnością i dokładnością. Napędzane narzędzia i transporter wiórów sprawiają, że jest to idealna maszyna do pracy w ciężkich warunkach.

Tokarka idealna do obróbki wałków o dużych średnicach.

Idealna do produkcji dużych serii. Dzięki napędzanym narzędziom, precyzyjnie wykonuje detale, a transporter wiórów usprawnia cały proces.

Maszyna jest szybka i bardzo dokładna, doskonała do intensywnej pracy.

Tokarka działa sprawnie, idealna do produkcji seryjnej wałków o dużych średnicach.

Tokarka sprawdza się świetnie przy produkcji detali. Napędzane narzędzia i odbiór detalu z transporterem wiórów zwiększają efektywność pracy.

Bardzo precyzyjna maszyna, idealna do obróbki wałków i innych detali.

Tokarka CNC CK7150 LT 12x750 z napędzanymi narzędziami to idealna maszyna do produkcji seryjnej. Dodatkowy transporter wiórów to ogromna zaleta!

CNC Lathe CORMAK CK7150LT12x1000 Driven Tools SIEMENS SINUMERIK

The CORMAK CK7150LT12x1000 lathe features a compact design with an attractive shape, convenient operation and maintenance, and a wide processing capacity. It is suitable for machining non-ferrous, ferrous, and non-metallic materials. This lathe can perform cylindrical, conical, and face turning, ...More

CNC Lathe CORMAK CK71560 LT 12x1500 Driven Tools SIEMENS SINUMERIK

The CORMAK CK71560 LT 12x1500 lathe features a compact and ergonomic design that ensures convenient operation and maintenance while offering wide processing capabilities. It is suitable for machining non-ferrous, ferrous, and non-metallic materials. This lathe can perform cylindrical, conical, and ...More

CNC Lathe CORMAK CK7170x1000 LT12 Driven Tools SIEMENS SINUMERIK

The CORMAK CNC lathe with C-axis and driven tools meets the needs of modern industry. Based on SIEMENS technology and Schneider components, this machine combines innovation with durability. Its large working area, high rigidity of the slant bed and milling capability make it an excellent machining ...More

CNC Lathe CORMAK CK7170X2000 LT12 Driven Tools BMT45 12-Position Tool Turret SIEMENS SINUMERIK 808D

The modern CORMAK CNC slant-bed lathe is designed for precise and efficient machining of medium and large-sized components. With a turning capacity of up to Ø700 mm and a workpiece length of up to 2000 mm, combined with a C-axis and driven tools, it is the ideal machine for producing complex parts. ...More

CNC Lathe CORMAK CK7170X1500 LT12 Driven Tools BMT45 Hydraulic Chuck SIEMENS SINUMERIK 808D

A modern CNC lathe from CORMAK with a slant bed designed for precise and efficient machining of medium and large components. A turning capacity up to Ø700 mm and a workpiece length up to 1500 mm, combined with a C-axis and driven tools, make it ideal for producing complex parts. The BMT 45 ...More

CNC Lathe CORMAK 400x1000 LT1 Driven Tools Siemens Sinumerik

High-performance flat-bed CNC lathe designed for both small-batch and medium-series production. The machine supports external, internal, spherical turning and thread cutting. Integrated fixed machining cycles for facing, longitudinal turning, taper turning, threading, plunge cutting and contouring ...More

CNC Lathe CORMAK CK7160 LT 12x1000 Driven Tools SIEMENS SINUMERIK

Industrial slant-bed lathe ideal for small and medium-scale production. Equipped for turning external, internal, and spherical surfaces, as well as threading. Fixed cycle control simplifies programming, while the additional driven tool allows off-axis drilling and milling operations. ...More

CNC Lathe CORMAK CK7140LT 12x750 SIEMNS SINUMERIK with Slant Bed and Driven Tools

High-efficiency industrial slant-bed CNC lathe CK7140LT 12x750 with compact, user-friendly design for machining ferrous, non-ferrous and non-metallic materials. Capable of turning cylindrical, conical, face, boring, grooving, threading and spherical surfaces. Equipped with a 12-position turret ...More

CNC Lathe CORMAK CKT360x750 with Driven Tools and SIEMENS SINUMERIK

Efficient flat-bed CNC lathe ideal for serial and small-batch machining. It performs external, internal, spherical and thread turning. The built-in canned cycles simplify programming, while the additional driven tool enables drilling and milling operations off the turning axis. ...More

2024-12-05

Zdecydowanie polecam

To maszyna, która łączy niezawodność, precyzję i wygodę. Napędzane narzędzia oraz transporter wiórów to świetne udogodnienia w produkcji seryjnej.