The basket is empty.

The CORMAK XN840 CNC Toolroom Milling Machine features a vertical milling head swivelling within ±60° and a horizontal milling setup. It is designed primarily for toolrooms and workshops producing complex, high-quality parts. Despite its compact size, the robust structure allows machining of relatively large workpieces with high precision and stability.

The CORMAK XN840 CNC Tool Milling Machine is an advanced CNC system designed for precise metal machining in a wide range of industrial applications. Equipped with Siemens Sinumerik 808D control and dual worktables, this metalworking machining centre offers reliability, accuracy and operational flexibility.

The CORMAK XN840 combines a rigid construction with modern technology, providing users with significant advantages in production processes:

The CORMAK XN840 CNC Machining Centre is an excellent solution for workshops and production plants seeking a precise, versatile and durable milling machine for metalworking.

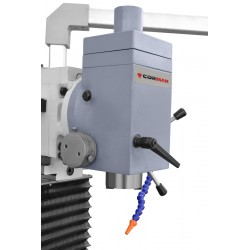

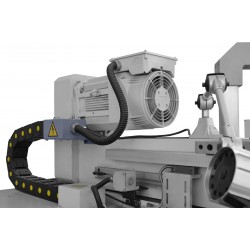

The CORMAK XN840 is designed with a focus on durability, precision and ease of operation. Key components include:

The robust cast-iron structure provides outstanding rigidity and vibration damping. The horizontal table 800 × 400 mm with 6 T-slots and the vertical table 1200 × 250 mm with 3 T-slots allow secure clamping of workpieces with a maximum load of 200 kg.

The ISO 40 spindle with a speed range of 40–2000 rpm is driven by a 3.0 kW motor, ensuring high cutting efficiency. The spindle-to-table distance (180–580 mm horizontal, 150–550 mm vertical) and the swivelling vertical head (±60°) allow machining of various part geometries and dimensions.

Linear guides and precision servo drives powered by a 1.3 kW feed motor ensure smooth motion in X, Y, Z axes (500 × 400 × 400 mm travel) with stepless feed (5–500 mm/min) and rapid feed 1200 mm/min, reducing positioning errors and enhancing dynamic accuracy.

Standard Siemens Sinumerik 808D (optional Fanuc) with an IP65-rated control panel enables precise programming and machining optimisation. Full CAD/CAM integration allows easy adaptation to complex production tasks.

The CORMAK XN840 CNC Milling Machine provides exceptional accuracy thanks to advanced CNC control and solid construction. Stepless feed (5–500 mm/min) and rapid feed 1200 mm/min optimise toolpaths, shortening cycle times and increasing productivity. The 3.0 kW motor and 40–2000 rpm spindle make it ideal for precision operations such as milling, drilling, slotting and tapping.

The CORMAK XN840 Metalworking Centre is suitable for demanding sectors such as:

With its versatile worktables and configurable CNC options, this CNC machining centre is a perfect solution for workshops and production facilities.

The CORMAK XN840 CNC Tool Milling Machine offers professional CNC systems from Siemens and Fanuc, providing precision, efficiency and ease of use.

Sinumerik 808D is a compact CNC control system for metalworking machines, providing:

Fanuc is an optional CNC control system offering:

Choose the CNC control that best fits your production requirements to maximise precision and efficiency!

| Table size | 800 × 400 mm |

| Table travel (X/Y/Z) | 500 × 400 × 400 mm |

| Number of T-slots | 6 |

| T-slot width | 14 mm |

| Vertical table size | 1200 × 250 mm |

| Number of T-slots on vertical table | 3 |

| T-slot spacing | 63 mm |

| Table-to-column distance | 165 mm |

| Maximum table load | 200 kg |

| Spindle taper | ISO 40 |

| Horizontal spindle-to-table distance | 180–580 mm |

| Vertical spindle-to-table distance | 150–550 mm |

| Vertical head swivel | ±60° |

| Max spindle-to-column distance | 565 mm |

| Spindle speed range | 40–2000 rpm (18 speeds) |

| Feed rate (X/Y/Z) | 5–500 mm/min |

| Rapid feed (X/Y/Z) | 1200 mm/min |

| Feed motor power | 1.3 kW |

| Main motor power | 3.0 kW |

| Coolant pump power | 0.9 kW |

| Dimensions | 1740 × 1540 × 2020 mm |

| Weight | 2450 kg |

*The quoted price refers to the machine only and excludes optional/additional equipment, installation, transport and training — please contact our consultant for more details.

As an experienced CNC machine manufacturer, CORMAK has been providing reliable industrial solutions for over 20 years. Our CNC machines meet European quality standards, are CE certified and backed by professional service. With over 15,000 m² of warehouse space and a skilled technical team, we ensure full support and consultancy.

By choosing CORMAK machining centres, you invest in precision, reliability and long-term production efficiency.

Boost your production precision and efficiency with the CORMAK XN840 CNC Milling Machine. Contact our team for more information, a customised quote or to schedule a demonstration.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CNC Toolroom Milling Machine CORMAK XL8140

The CORMAK XL8140 CNC Toolroom Milling Machine is designed for toolrooms and workshops producing complex, high-quality components. Despite its compact size, the solid structure enables machining of relatively large workpieces with high precision and stability. Equipped with Siemens Sinumerik 808D ...More

CNC Toolroom Milling Machine CORMAK XN830

The CORMAK XN830 CNC Toolroom Milling Machine is equipped with a vertical milling head tiltable by ±60° and a horizontal milling setup. Designed primarily for toolrooms and workshops producing complex, high-quality components, its construction allows machining of relatively large workpieces ...More

Write your review

* Required fields

I accept privacy policy rules