The basket is empty.

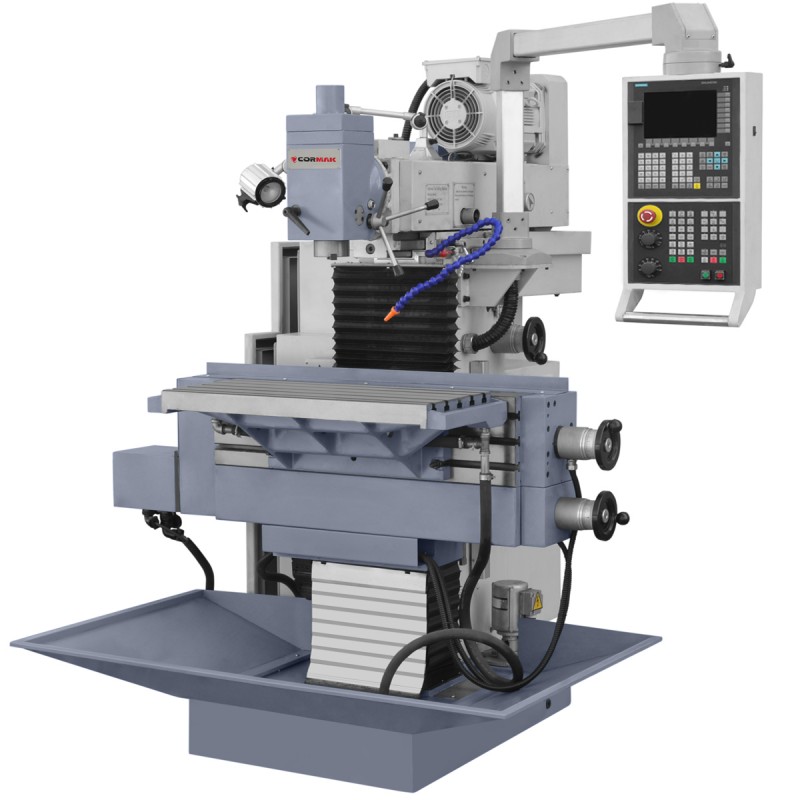

The CORMAK XN830 CNC Toolroom Milling Machine is equipped with a vertical milling head tiltable by ±60° and a horizontal milling setup. Designed primarily for toolrooms and workshops producing complex, high-quality components, its construction allows machining of relatively large workpieces despite its compact dimensions.

The CORMAK XN830 CNC Toolroom Milling Machine is an advanced CNC machine designed for precision metal machining in demanding industrial environments. Equipped with Siemens Sinumerik 808D control and a robust structure, this metalworking machining centre ensures reliability, high precision and operational versatility.

The CORMAK XN830 CNC Toolroom Milling Machine combines a compact design with advanced technology, offering users major benefits in production processes. Key advantages include:

The CORMAK XN830 CNC Machining Centre is the perfect solution for workshops and production facilities seeking a precise, versatile and reliable milling machine for metal machining.

The CORMAK XN830 CNC Toolroom Milling Machine is designed for durability, precision and ease of operation. The key components include:

The massive cast-iron frame made of high-quality materials ensures exceptional rigidity and vibration damping. The worktable of 750x320 mm with 5 T-slots (14 mm wide) allows secure clamping of workpieces up to 200 kg.

The spindle with an ISO40 taper and a speed range of 40–1600 rpm, powered by a 3.0 kW motor, provides high cutting performance. The spindle-to-table distance (105–495 mm vertical, 135–535 mm horizontal) and the milling head swivel (±60°) allow machining of components of various sizes and shapes.

Linear guides and precision servo drives ensure smooth motion in the X and Y axes, with manual longitudinal feed 405 mm and cross feed 390 mm, automatic longitudinal feed 395 mm and cross feed 380 mm, minimising positioning errors and ensuring dynamic performance.

Standard Siemens Sinumerik 808D (optional Fanuc) control with a compact IP65-rated panel enables precise programming and machining optimisation. Integration with CAD/CAM systems facilitates adaptation to complex production projects.

The CORMAK XN830 CNC Toolroom Milling Machine offers excellent precision thanks to its advanced CNC control system and robust construction. Manual feeds (405 mm longitudinal, 390 mm cross) and automatic feeds (395 mm longitudinal, 380 mm cross), combined with a spindle speed range of 40–1600 rpm, enable optimised tool paths, shorter cycle times and increased efficiency. The powerful 3.0 kW motor makes the machine ideal for precise operations such as milling, drilling, keyway cutting and threading.

The CORMAK XN830 CNC Machining Centre is suitable for a wide range of demanding industries, including:

With its versatile worktable and advanced configuration options, this CNC machining centre is an excellent choice for toolrooms and production plants.

The CORMAK XN830 CNC Toolroom Milling Machine provides professional CNC control systems from renowned manufacturers Siemens and Fanuc, ensuring precision, performance and ease of use.

Sinumerik 808D is a compact CNC control system for metalworking machines, offering:

Fanuc is an optional CNC control system for CNC machines that offers:

Select the CNC control that best meets your requirements to increase efficiency and precision in production processes!

| Table dimensions | 750 mm × 320 mm |

| Table travel | 450 × 320 mm |

| Number of T-slots | 5 |

| T-slot width | 14 mm |

| Manual longitudinal feed | 405 mm |

| Automatic longitudinal feed | 395 mm |

| Manual cross feed | 390 mm |

| Automatic cross feed | 380 mm |

| Maximum table load | 200 kg |

| Spindle taper | ISO40 |

| Vertical spindle-to-table distance | 105 – 495 mm |

| Horizontal spindle-to-table distance | 135 – 535 mm |

| Milling head swivel angle | ±60° |

| Spindle speed range | 40–1600 rpm |

| Main motor power | 3 kW |

| Overall dimensions | 1820 × 1640 × 1710 mm |

| Weight | 2200 kg |

*The price quoted applies to the machine only and excludes optional/additional equipment, installation, transport and training — please contact our consultant for more information.

As an experienced CNC machine manufacturer, CORMAK has been delivering reliable industrial solutions for over 20 years. Our CNC machining centres meet the highest European safety and quality standards and are supported by professional service. With a well-equipped logistics and warehouse base (over 15,000 m²) and a team of qualified specialists, we provide comprehensive technical assistance and expert advice.

By choosing CORMAK machining centres, you invest in precision, reliability and long-term efficiency in your production.

Increase the performance and precision of your production with the CORMAK XN830 CNC Toolroom Milling Machine. Contact our team for detailed information, an individual quotation or to arrange a machine demonstration.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CNC Toolroom Milling Machine CORMAK XN840

The CORMAK XN840 CNC Toolroom Milling Machine features a vertical milling head swivelling within ±60° and a horizontal milling setup. It is designed primarily for toolrooms and workshops producing complex, high-quality parts. Despite its compact size, the robust structure allows machining of ...More

CNC Toolroom Milling Machine CORMAK XL8140

The CORMAK XL8140 CNC Toolroom Milling Machine is designed for toolrooms and workshops producing complex, high-quality components. Despite its compact size, the solid structure enables machining of relatively large workpieces with high precision and stability. Equipped with Siemens Sinumerik 808D ...More

Write your review

* Required fields

I accept privacy policy rules