-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

100,00 PLN

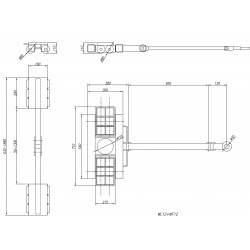

Machine moving skate set WL12 + WF12 – reliable support for relocating heavy loads

Machine moving skate set WL12 + WF12 is a professional solution designed for safe and precise relocation of heavy machinery, equipment and industrial structures. With an impressive total load capacity of up to 24,000 kg, the set is suitable wherever reliability, precision and maximum transport safety are required. Its compact design and excellent technical parameters make it an indispensable tool in the industrial, construction and service sectors.

Main advantages of the WL12 + WF12 set

- High load capacity – static load capacity up to 12,000 kg per unit, enabling transport of extremely heavy loads.

- Stable construction – 12 rollers sized 80×80 mm on each skate ensure even load distribution.

- Polyurethane treads – resistant to wear and damage, effectively dampen vibrations and protect floor surfaces.

- Low loading height – 110 mm – allows easy positioning under the load without the need for significant lifting.

- High manoeuvrability – WL12 steering handle with a length of 1080 mm and a steering angle of ±90° enables precise manoeuvring even in confined spaces.

- Adjustable skate spacing – spacing range from 630 to 1880 mm allows adaptation to various load dimensions.

Design and technology – robust steering skate and load skate adapted to extreme loads

The set consists of two complementary components: the WL12 steering skate and the WF12 load skate. Both components are manufactured from high-quality materials resistant to deformation, ensuring long service life and safe operation in demanding industrial environments.

Design characteristics:

- WL12 – steering skate with a single support point and a load-bearing surface of Ø155 mm. Ideal for precise control of the transported load.

- WF12 – load skate with two support points and a wide load-bearing surface of 290×180 mm. Equipped with a 1300 mm connecting bar allowing adjustment of spacing to suit user requirements.

- 80×80 mm rollers – each unit equipped with 12 rollers, providing a large contact surface and reducing point load on the floor.

Precision and safety in heavy machinery relocation

The use of polyurethane treads not only protects floor surfaces but also improves operator comfort by damping vibrations and reducing noise. Optimised load distribution and structural rigidity minimise the risk of load tipping or uncontrolled movement. The set enables smooth movement even at the maximum dynamic load of 7,200 kg per unit.

Applications – an ideal solution for industry, service and logistics

Machine moving skate set WL12 + WF12 is widely used across many sectors:

- heavy industry – relocation of machine tools, presses, generators and transformers,

- industrial construction – transport of steel structures, prefabricated elements and process installations,

- logistics and warehousing – handling of large and heavy components,

- installation and service – support for assembly and disassembly of industrial machinery.

Standard equipment

- 1 × WL12 steering skate

- 1 × WF12 load skate

- Connecting bar with a length of 1300 mm

- Steering handle with a length of 1080 mm (WL12)

Technical data of the WL12 + WF12 set

WL12 technical parameters

|

|---|

| STATIC LOAD CAPACITY |

12,000 kg |

| DYNAMIC LOAD CAPACITY |

7,200 kg |

| ROLLER SIZE |

80×80 mm |

| NUMBER OF ROLLERS |

12 |

| LOADING HEIGHT |

110 mm |

| LOAD-BEARING SURFACE PER UNIT |

Ø155 mm |

| SUPPORT POINTS |

1 |

| STEERING HANDLE LENGTH |

1080 mm |

| STEERING ANGLE |

±90° |

| DIMENSIONS (L × W) |

380×710 mm |

WF12 technical parameters

|

|---|

| STATIC LOAD CAPACITY |

12,000 kg |

| DYNAMIC LOAD CAPACITY |

7,200 kg |

| ROLLER SIZE |

80×80 mm |

| NUMBER OF ROLLERS |

12 |

| LOADING HEIGHT |

110 mm |

| LOAD-BEARING SURFACE PER UNIT |

290×180 mm |

| SUPPORT POINTS |

2 |

| CONNECTING BAR LENGTH |

1300 mm |

| SKATE SPACING WIDTH |

630–1880 mm |

Professional control over heavy loads – choose WL12 + WF12

WL12 + WF12 set is an investment in safety, efficiency and reliable operation under the most demanding transport conditions. Ensure the highest standard of load handling with a solution proven in heavy industry and technical service applications.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

2024-01-30

Wysoka jakość

warto brać