Why is worth to choose a fiber laser?

There are many types of sheet metal cutting machines on the market. So why is worth to choose a fiber laser, not a plasma cutter or a water cutter?

Fiber lasers, compared to other technologies, enable quick and easy realization of the order. The most important advantages of a fiber laser are:

- lower energy costs - The use of specialized solutions ensuring high energy efficiency when converting electricity into a laser beam allows to reduce the power consumption by more than 10 times compared to other technologies. This is particularly important in view of the ever-increasing energy prices.

- low operating costs - failure-free optical fiber and a small number of components that may wear out

- universal using - Fiber laser enables cutting any shapes in materials such as: special sheets, black and stainless steel, copper, brass, aluminum, titanium. The laser can also cut open sections, pipes and profiles

- easy using - modern software and simple interface

- compactness - the use of a fiber laser saves 30% of space

- reliability - Fiber lasers are characterized by a very long service life and do not require frequent maintenance. Unlike CO2 lasers, where there are complex mirror and lens systems, fiber lasers are based on modern technology using a maintenance-free fiber optic cable.

- work speed -the cutting speed of a fiber laser is usually 3 times faster than the operating speed of plasma cutting devices and CO2 lasers. After laser cutting, the edge does not require reworking, which significantly speeds up the production process of a given detail.

- future-proof - Fiber lasers are becoming the basic machine in industrial plants as well as in craft plants where steel is processed. We, as the Cormak company, see how today laser cutters are increasingly replacing plasma burners or CO2 lasers. It becomes unprofitable to buy plasma with a cutting thickness of 8-10 mm, because a laser cutting such thickness can already be purchased for about PLN 150,000. The fiber laser cuts, engraves or even marks elements much faster and more accurately. The laser is also unrivaled in cutting very small details, e.g. 1, 2, 3 mm.

What power of a fiber laser?

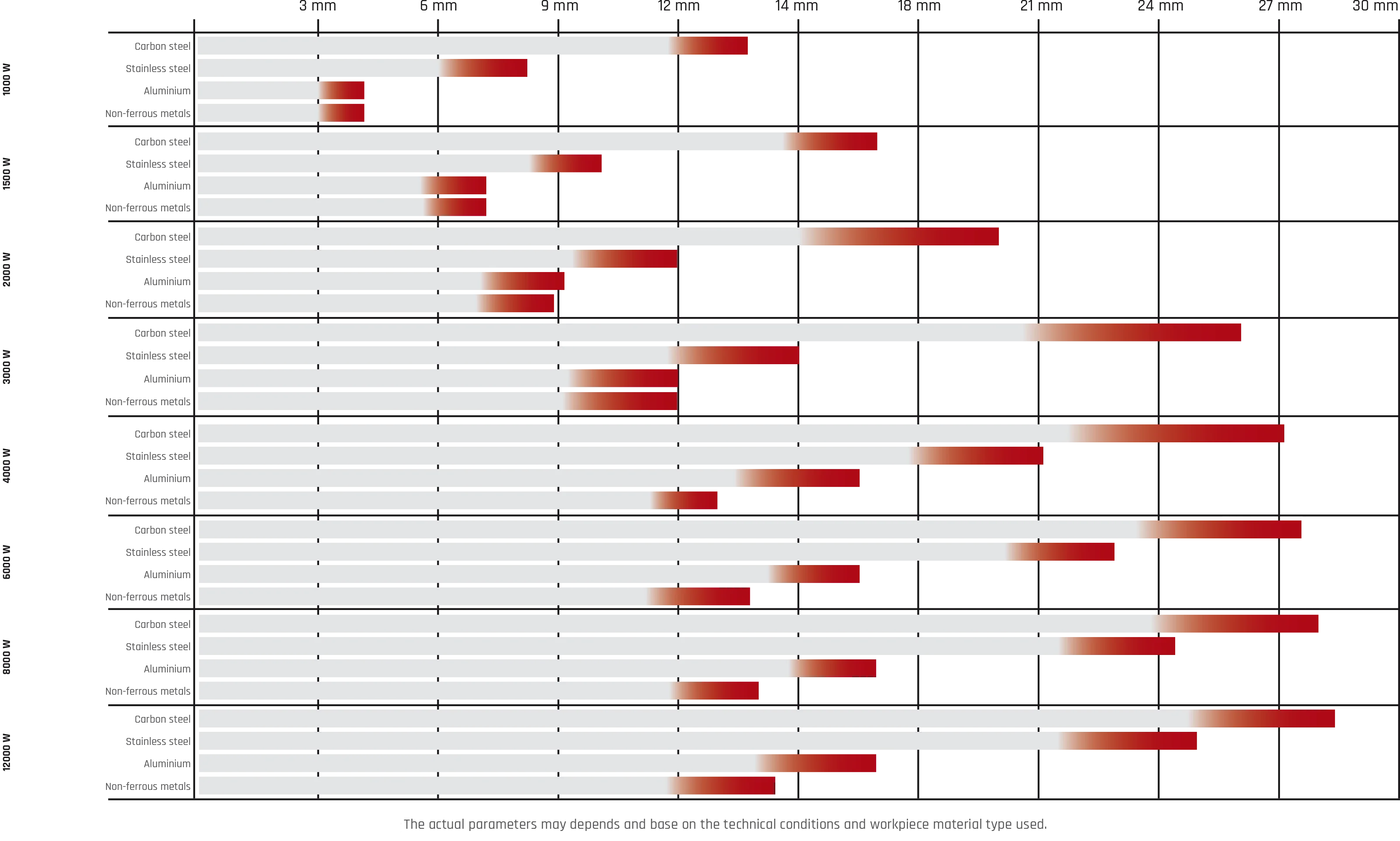

The power of the laser source is one of the most important parameters during purchasing. Choosing the right power affects costs and working time. Depending on the power of the source, we can cut thicker sheets as shown in the table below. To avoid mistakes in choosing the right laser power, you can talk to our sales department, who will be happy to advise you in choosing the right solution.

Design of a fiber laser and the principle of operation

The laser power source is a semiconductor diode pump that emits photons and transmits them through a fiber optic cable. In this type of technology, a glass-based fiber optic cable is used, which means that the cable can be long and there is no loss of power. The light traveling through the optical fiber then passes through a collimating lens which causes the photons to travel parallel to each other. Then the beam passes through the optical system, which focuses the beam at a specific point, which enables cutting. Fiber lasers, thanks to their design, allow to achieve high conversion of electric energy into the laser beam.

Fiber laser software. Why is it so important?

The laser software is one of the most important factors influencing the efficiency and productivity of work. The CAD / CAM software offers the user many functions and configuration possibilities. The nesting function significantly optimizes the cutting process and saves the material being cut. The use of a WiFi communication system allows for remote control of the device's operation.

Is the service important when choosing a company and laser?

Fiber lasers, like any device, can fail, which usually generates unnecessary downtime and costs. Repairing such an advanced device requires appropriate skills. Therefore, when buying a laser, it is worth paying attention to after-sales care. CORMAK lasers are assembled from scratch in our company, which is why we know the machine exactly and we are able to quickly locate the problem, and then remotely or by visiting a service technician to quickly eliminate the defect. We have an extensive warehouse of spare parts available immediately. The CORMAK company guarantees the continuous operation of the laser source. If defects are found, the source is replaced with a new one and downtime is reduced to a minimum.

What to consider during choosing a fiber laser?

- availability of the service guarantee

- availability of spare parts

- the size of the machine and worktable - during choosing a laser, you should think carefully about your present and future needs. The standard dimensions of the table are 1500x3000 mm. There are also lasers with a table of 2000x4000 mm and 2500x6000 mm, as well as lasers of much larger sizes, e.g. 12000x2500 mm.

- type and thickness of the material being cut - currently on the market of laser cutters there are powers from 1-30KW. Specify the type of material to be processed and its thickness, as well as whether pipes and profiles will also be cut.

- Will it be a repetitive production or will each day bring a different challenge (e.g. service cut)

There are lasers for various applications on the laser market. The most frequently chosen lasers are those for cutting flat sheets of metal, which can be equipped with an automatic sheet feeding system, a storage system or a coil sheet feeding system. Additionally, the laser can be equipped with a 2D or 3D cutting head. In addition to fiber lasers for sheet metal cutting, there are also fiber lasers for pipes and profiles. They can be with manual material loading, semi-automatic or automatic part loading and collection system. These lasers also have 2D and 3D cutting heads. The offer also includes "2in1" lasers, i.e. for cutting sheet metal, pipes and profiles.

Fiber laser and plasma cutter

A plasma cutter is a good solution for cutting thick materials and applications where the quality of the edge of the material being cut is not the most important. It should be remembered that the heat-affected zone in the workpiece is larger and that the edges are bevelled from 4-6 degrees. Plasma cutters or CNC plotters are much cheaper than laser cutters, but also much slower.

Fiber lasers ensure the fastest and relatively easy execution of the order, starting with the design and ending with the finished detail. Laser cutters ensure high precision, cutting quality, efficiency and cutting flexibility, therefore they successively displace older technologies still used in industry. Every entrepreneur who contracts an external company with laser cutting should confront their bills with the leasing installment. It may turn out that it will be cheaper and faster to have a laser in your own machine park than to outsource the service to other companies. You may also find that so much has already been spent on services, that the laser has already been paid for, but is not physically in your assets.