Which plasma cutter gas to choose?

Which Gas to Choose for a Plasma Cutter?

The choice of gas is a crucial element in the plasma cutting process, as it significantly affects the quality and parameters of the cut. Plasma cutting is a widely used technique in the industry for precision cutting of various metals. Selecting the right gas is essential for the quality and efficiency of the process. In this article, we will discuss which gas to choose for plasma cutting, considering various aspects. Read on to learn more.

Plasma Cutting — Which Gas?

The answer to the question "Which gas should I choose for plasma cutting?" is key to achieving optimal results. Each gas has its specific properties, advantages, and disadvantages, determining its use in various industries. Here are detailed insights into the different gases used in plasma cutting machines.

-

Air: Air is the most commonly used gas in plasma cutting due to its availability and low cost. It is versatile and works well for cutting various materials. However, it can cause oxidation of the edges, reducing the quality of the cut. Air is ideal for workshops and the metal industry, where low costs are critical. However, it requires more frequent replacement of electrodes and nozzles, slightly increasing operating costs.

-

Nitrogen: Nitrogen is ideal for cutting stainless steel and aluminum, providing clean, oxidation-free edges. It is more expensive than air but offers higher cutting quality. Nitrogen is commonly chosen by the aerospace and automotive industries, where high quality standards are required.

-

Argon: Argon works exceptionally well for cutting aluminum and non-ferrous metals, providing smooth and precise edges. Although relatively expensive, it offers excellent cutting quality.

-

Oxygen: Oxygen is used in specialized applications where very high cutting temperatures are required, making it ideal for cutting thick materials. It is used as a plasma gas when cutting low-alloy and unalloyed steel. In contact with oxygen, the viscosity of the molten material decreases, making it more fluid, which in turn helps achieve edges free of slag impurities and top edges without unwanted rounding.

-

Gas Mixtures: Gas mixtures, such as argon with hydrogen, combine the benefits of individual gases, optimizing cutting quality. They offer high precision and clean edges and are best used in applications where any inaccuracy is critical. These solutions are applied in industries where the highest cutting quality is a priority.

Criteria for Selecting Gas for Plasma Cutting

The type of material determines the choice of gas. Aluminum is best cut with argon, while stainless steel prefers nitrogen. Material thickness also influences gas choice. Oxygen is ideal for thick materials, while thinner materials can be cut with air or nitrogen. High-quality cuts require gases like argon or gas mixtures, while air is suitable for less demanding applications. The budget also plays a role in gas selection. Air is the cheapest, while argon and gas mixtures are more expensive but offer superior results.

After reading this article, the choice of the right gas for a plasma cutter should no longer be in doubt. CORMAK, an industrial machinery manufacturer, encourages you to explore our full range of products. We offer specialized industrial machines and laser machines, including:

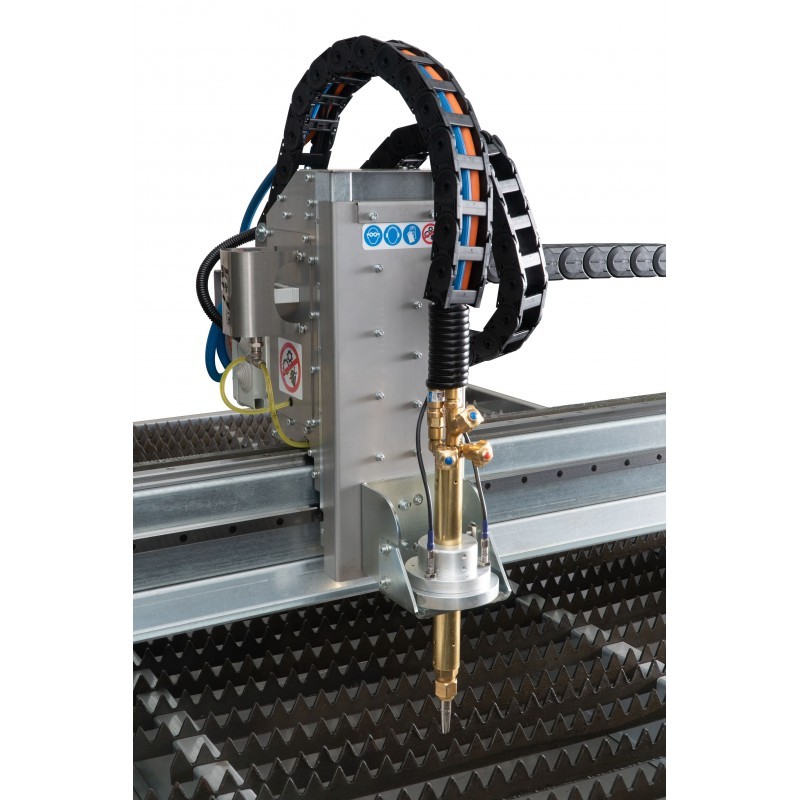

- CNC cutting machines

- Plasma cutters

- Plasma cutting machines