The basket is empty.

The modern Cormak CNC lathe with an inclined bed has been designed for precise and efficient machining of medium and large workpieces. The turning capacity of up to Ø600 mm and the length of the workpiece up to 2000 mm, combined with the C axis and driven tools, make it an ideal machine for the production of complex parts. A 12-position tool head, SIEMENS servo drives, linear guides and full hydraulics - all this makes it a professional tool for continuous operation. The SINUMERIK 808D controller (SINUMERIK 828 OPTION, FANUC) ensures easy operation and the ability to edit programs directly on the machine.

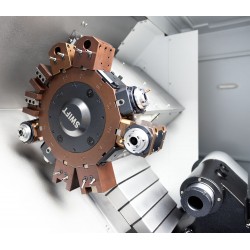

A modern CNC lathe with a solid, slanted bed and a BMT 45 tool head offers the highest precision, efficiency and versatility of machining. The machine was designed to work in production conditions - it allows for comprehensive machining of details using the C axis and driven tools. Thanks to the use of renowned Siemens and Schneider components, the lathe guarantees long life and reliability.

| Turning diameter over bed | 600 mm |

| Turning diameter over support | 370 mm |

| Max workpiece length | 2000 mm |

| Travel in X / Z axis | 1260/290 mm |

| Through spindle | 72 mm |

| Spindle speed | 2500 rpm /min. |

| Spindle motor | SIEMENS 11 kW (15 kW) |

| Lathe chuck | hydraulic 3-jaw, Ø305 mm |

| Tool head | BMT 45, 12 positions (driven tools) |

| Positioning accuracy X/Z axis | 0.001 mm |

| Tool dimensions | 20 x 20 mm |

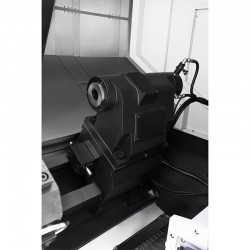

| Hydraulic tailstock | Ø90 mm sleeve, 140 mm stroke |

| Tailstock taper | MK5 |

| Dimensions L/W/H | 6000 x 2300 x 2210 mm |

| Weight | 7100 kg |

We offer professional CNC controls from renowned brands Siemens and Fanuc, which ensure precision, efficiency and ease of use. Our solutions are ideal for both smaller workshops and demanding industrial applications.

Siemens Sinumerik 808D is a modern, economical CNC control dedicated to entry-level lathes and milling machines. The system was designed with small and medium-sized enterprises in mind, offering:

Sinumerik 828D is a professional CNC control designed to work with milling machines and lathes requiring greater precision and efficiency. Its key features include:

CNC LATHE CORMAK 400x500 HYDRAULIC 12-TOOL HOLDER SIEMENS SINUMERIK 808D

The CK400 Slant Bed CNC Lathe is an advanced machine with a solid, monolithic bed structure, designed for high precision and machining efficiency. The use of precise HIWIN linear guides ensures stable and accurate operation, even when machining complex details. The machine is equipped with a ...More

CNC LATHE CORMAK 400x1000 HYDRAULIC 12-TOOL HOLDER SIEMENS SINUMERIK 808D

Our CK400 Slant Bed CNC Lathe is a superb machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a hydraulic chuck ...More

CNC Lathe CK7170X1000 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

CNC lathe Cormak is a response to the needs of modern industry. Based on SIEMENS technology and Schneider components, the machine combines modernity with durability. Large workspace, high rigidity of the slanted bed make this machining center perfect for tool shops, serial and unit production. The ...More

CNC Lathe CK7150 x1000 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

CK7150x1000 lathe is characterized by compact structure with attractive shape, convenient operation and maintenance, and wide processing capacity. It is suitable for processing non-ferrous metal, ferrous metal and non-metallic workpieces. This lathe can perform cylindrical, conical, end face ...More

CK7135A CNC Lathe with Inclined Bed

This lathe provides not only precise machining but also high X/Z axes positioning repeatability = 0.006 mm (compared to 0.01 mm for ordinary CNC lathes). This is possible due to the factory mounted ball bearings and innovative design solutions implemented in the machine. By default, it comes with a ...More

CK7135AP CNC Lathe with Inclined Bed

This lathe provides not only precise machining but also high X/Z axes positioning repeatability = 0.006 mm (compared to 0.01 mm for ordinary CNC lathes). This is possible due to the factory mounted ball bearings and innovative design solutions implemented in the machine. By default, it comes with a ...More

CNC Lathe CK7160x1500 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

CK71560x1500 lathe is characterized by compact structure with attractive shape, convenient operation and maintenance, and wide processing capacity. It is suitable for processing non-ferrous metal, ferrous metal and non-metallic workpieces. This lathe can perform cylindrical, conical, end face ...More

Our CNC lathe with an inclined bed CK350 is an excellent machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a ...More

The modern Cormak CNC lathe with an inclined bed has been designed for precise and efficient machining of medium and large workpieces. The turning capacity of up to Ø700 mm and the length of the workpiece up to 2000 mm, combined with the C axis and driven tools, make it an ideal machine for the ...More

CNC LATHE CK7170X4000 LT12 HYDRAULIC 12-TOOL HOLDER SIEMENS SINUMERIK 808D

The advanced slant bed CNC lathe was created for efficient machining of medium and large workpieces . The turning capacity of up to Ø700 mm and workpiece length up to 2000 mm allow for the production of even the most demanding elements. Thanks to the BMT 45 head with 12 positions , the machine is ...More

CNC LATHE CK7170X3000 LT12 HYDRAULIC 12-TOOL HOLDER SIEMENS SINUMERIK 808D

The advanced slant bed CNC lathe was created for efficient machining of medium and large workpieces . The turning capacity of up to Ø700 mm and workpiece length up to 2000 mm allow for the production of even the most demanding elements. Thanks to the BMT 45 head with 12 positions , the machine is ...More

CNC Lathe CK7170X1500 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

The modern Cormak CNC lathe with an inclined bed has been designed for precise and efficient machining of medium and large workpieces. The turning capacity of up to Ø700 mm and the length of the workpiece up to 1500 mm make it an ideal machine for the production of complex parts. A 12-position tool ...More

Our CK400 Slant Bed CNC Lathe is a superb machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a hydraulic chuck ...More

CNC Lathe CK7160X1000 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

Industrial slant bed lathe, perfect for serial and small-scale machining. Equipped with external, internal, spherical and thread turning functions. Canned cycle control makes programming easy, and an additional driven tool allows drilling and milling off the turning axis. fast tool head 12 positions. ...More

CNC Lathe CK7150 x750 HYDRAULIC 12 TOOL HOLDER SIEMENS SINUMERIK 808D

Industrial high-performance slant bed lathe CK7150x750 is characterized by a compact structure, convenient in operation and maintenance. Designed for machining non-ferrous metal, ferrous metal and non-metal components. The lathe can perform cylindrical, conical, end surface turning, boring, ...More

Our CNC lathe with an inclined bed CK350 is an excellent machine with a monoblock bed structure, guaranteeing high efficiency and precision. Equipped with high-precision HIWIN linear guides, this lathe enables efficient machining of even the most demanding workpieces. Standard settings such as a ...More