Technical parameters

| Max. sheet thickness (S235) |

up to 4.0 mm |

| Maximum cutting length |

2500 mm |

| Cutting angle |

1.5° |

| Number of strokes per minute |

6–20 |

| Back gauge travel |

600 mm |

| Motor power |

5.5 kW |

| Length |

3200 mm |

| Width |

1450 mm |

| Height |

1700 mm |

| Weight |

3200 kg |

Equipment:

-

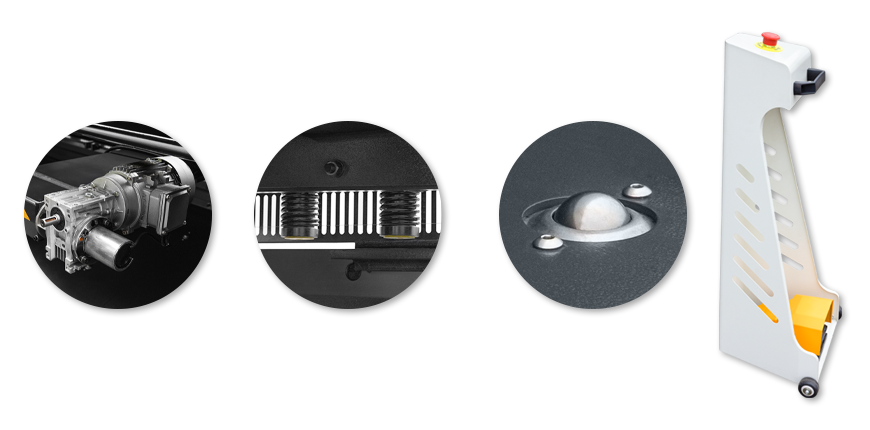

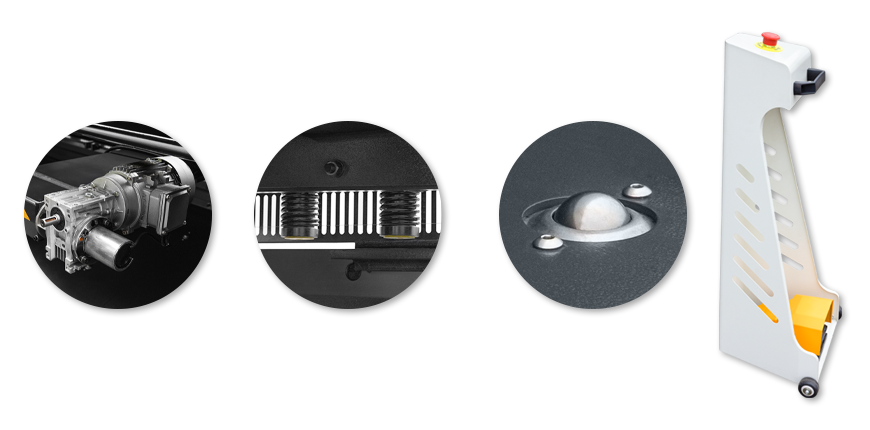

Rear back gauge driven by an electric motor (ball screw)

-

Hydraulic sheet clamps along the full cutting length

-

Adjustable blade gap

-

Ball sheet supports on the working table

-

Work area lighting

-

Front supports

-

Mobile foot controller

Rear chute:

The rear chute is equipped with ball guides, ensuring smooth and precise sliding of the cut pieces. This prevents any material fragments from remaining on the machine, increasing both efficiency and operator safety.

Control and functionality:

ESTUN E21S

- Control: Precise setting of the rear back gauge.

- Program memory: Storage of up to 40 programmes, each with a maximum of 25 steps.

- Return function: Automatic retraction of the gauge after cutting.

- Parameter saving: One-button saving of settings.

- Data protection: Parameter retention in case of power failure.

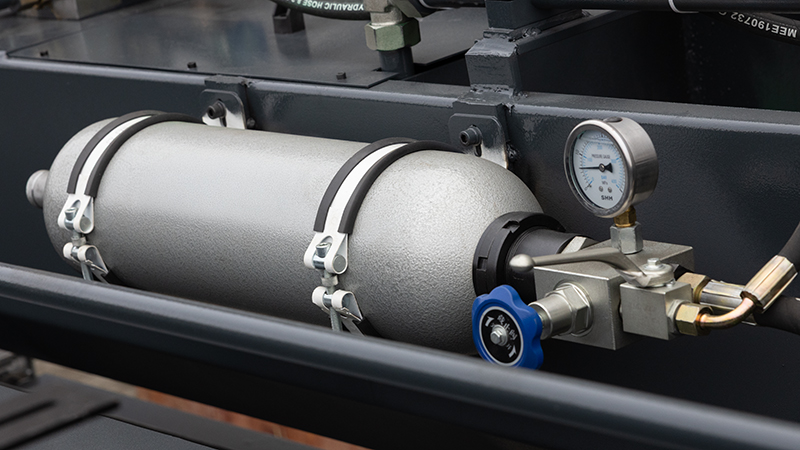

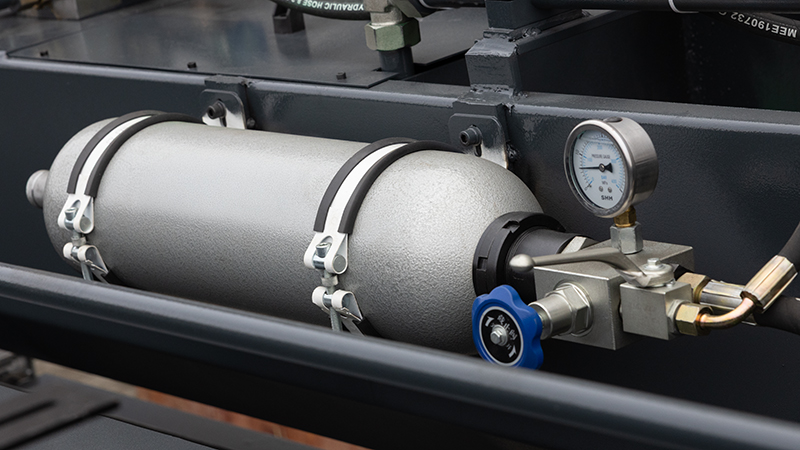

Steel hydraulic connections

The use of steel pipes in hydraulic systems instead of flexible rubber hoses significantly increases system tightness and minimises leakage risk. Owing to their rigidity and resistance to mechanical damage, steel pipes ensure long-lasting and reliable hydraulic connections.

Ergonomics

Thanks to the mobile controller and control panel mounted on a movable arm, the operator gains full freedom of movement throughout the machine’s working area. Additional LED lighting and a laser indicator ensure excellent visibility of the processed material, translating into precision and comfort under all working conditions.

Safety

For operator and workplace safety, our guillotine shears are equipped with numerous solutions to minimise risks during operation:

- Clearly marked warning labels

- Solid protective guards around cutting zones

- Rear light curtain

- Easily accessible emergency stops

Each machine is supplied with a user manual and a CE declaration of conformity, confirming compliance with European safety and quality standards.

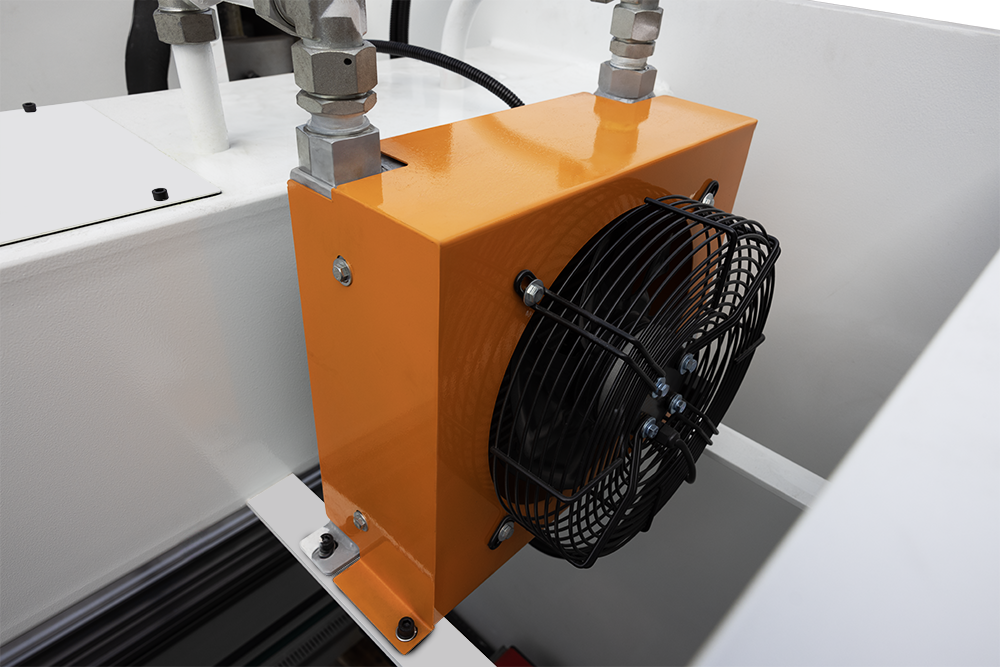

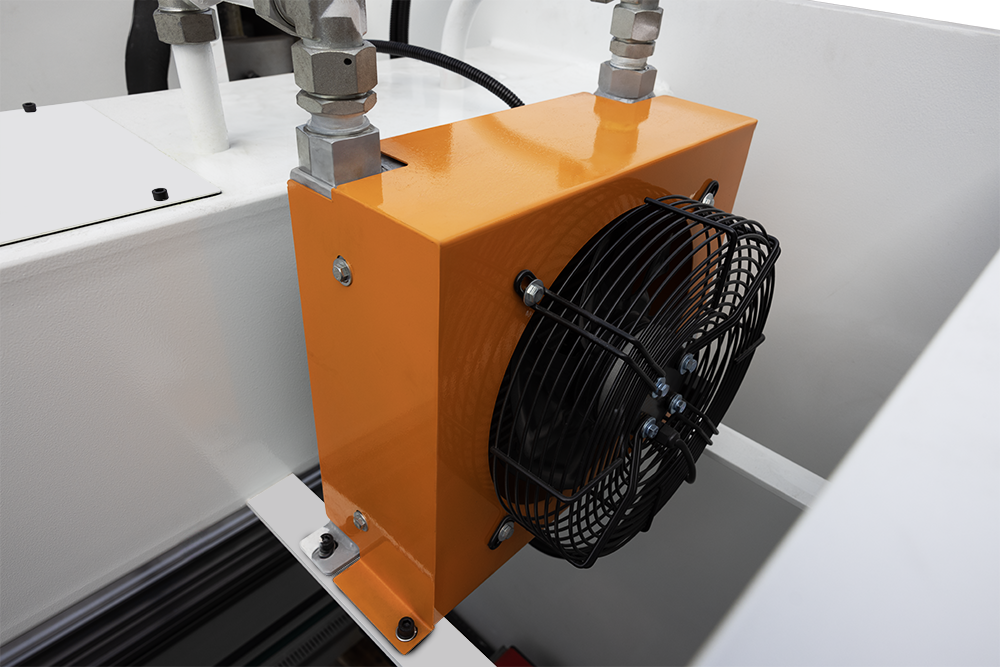

SCO – Oil Cooling System

As standard, the system guarantees stable machine operating parameters even after long, continuous use.

SKC – Pressure Control System

The pressure control system ensures reliable blade operation for many years.

Included with the machine

Telephone consultations with a specialist

You can always rely on support from a specialist.

Terms of cooperation

- 24-month warranty.

- The machine is brand new.

- Warranty and post-warranty service provided by the seller.

Training and Machine Commissioning

It is possible to arrange professional training and machine commissioning carried out by a Cormak technician — this service is priced individually.

Contact our advisor to get more information.

Contact us

Write your review

* Required fields

I accept privacy policy rules