The basket is empty.

The CORMAK ODL6K extraction and filtration system is a modern solution that ensures safe working conditions for operators and effective protection of laser system components against contamination and damage. Filtration of 99.9% removes harmful particles and fumes, ensuring clean air in the workplace.

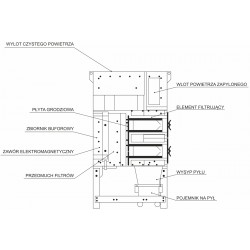

ODL6K features automatic filter cleaning system, efficient fan, and compact, robust design that allows for easy integration with various cutting systems. An additional advantage is the ergonomic waste drawer, which allows for quick and convenient emptying of collected waste.

This is a comprehensive solution that increases safety, improves work efficiency and extends the life of laser systems.

During laser processing, harmful fumes and dust are generated, which can negatively affect the operator's health, the quality of work and the service life of the machines. The modern ODL6K extraction system ensures effective filtration of contaminants and protection of the most important components of the laser system.

ODL6K combines automatic filter cleaning with compressed air, an efficient fan generating high negative pressure and filtration at the level of 99.9% for particles of 0.3 μm thanks to the use of appropriate filters. The system is equipped with automatic filter cleaning with compressed air, an efficient fan generating high negative pressure and 99.9% filtration for particles of 0.3 μm thanks to the use of appropriate filters. The system is equipped with ergonomic dirt drawer, which allows for quick and convenient removal of accumulated dust without the need for disassembly. Additionally, thanks to the modular design, it is possible to mount exhaust nozzles on both the left and right side of the device, which allows for flexible adjustment of the installation to the layout of the production hall.

ODL6K is a compact, efficient and reliable solution for any laser cutting system - increasing safety, comfort and work efficiency.

The main functions of the exhaust gas extraction and filtration system in the laser processing process are:

The most important advantages of the CORMAK ODL6K exhauster:

The exhauster has automatic filter cleaning using compressed air. Under the influence of pressure, the filter is "shaken off", which effectively cleans the filter cartridge and thus extends its life. Thanks to this, the system maintains its efficiency for a longer period of time.

The filter element used in the system is imported and made of high-quality material. The Nano-type fireproof filter features high filtration efficiency, retaining particles as small as 0.3 μm by over 99.9%.

A large dust collection drawer allows for convenient dust collection and cleaning, making system maintenance easier.

The motors used in the system are equipped with overload protection, ensuring a high level of protection and trouble-free operation.

A specially developed high-performance fan wheel generates high negative pressure, which enables effective removal of laser exhaust fumes and ensures high airflow efficiency.

The total system purification efficiency is 0.3 μm, and the efficiency is over 99.9%, which proves the high efficiency of the extraction in removing harmful particles from the air. In addition, it is characterized by a compact design, which facilitates operation and maintenance.

| Number of filter cartridges | 6 |

| Airflow | 6000 m³/h |

| Air Pressure | 3000 Pa |

| Filtration efficiency | 99.99% |

| Filter Size | 350x660 mm |

| Fan Power | 7.5 kW |

| Inlet Diameter | 300 mm |

| Weight | 590 kg |

| Dimensions (L x W x H) | 1150 x 1950 x 2250 mm |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Industrial smoke and dust extraction LDC-2L

Extraction and filtering systems are essential in the laser processing process. Their task is to safely remove smoke and dust, as well as protect the laser system components from damage. Filtration, including the use of a carbon filter, is a key stage of this process. The filter removes ...More

Industrial smoke and dust extraction TODC-4L

The LDC-6L extraction system is an advanced solution ensuring protection and efficiency in the laser processing process. Thanks to automatic filter cleaning, 99.9% filtration efficiency, efficient fan, and compact design, this system ensures operator safety, maintains the efficiency of laser ...More

Industrial fume and dust extraction LDC-4L

Extraction and filtering systems are necessary to ensure the safe work of operators and protect laser system components from damage. Filtration, including the use of a carbon filter, is a key step in the process, removing harmful substances and producing clean air. The key benefits of an advanced ...More

NEW Industrial smoke and dust extraction ODL4K

The CORMAK ODL4K extraction and filtration system is a modern solution that provides safe working conditions for operators and effective protection of laser system components against contamination and damage. Filtration at a level of 99.9% removes harmful particles and fumes, guaranteeing clean air ...More

Write your review

* Required fields

I accept privacy policy rules