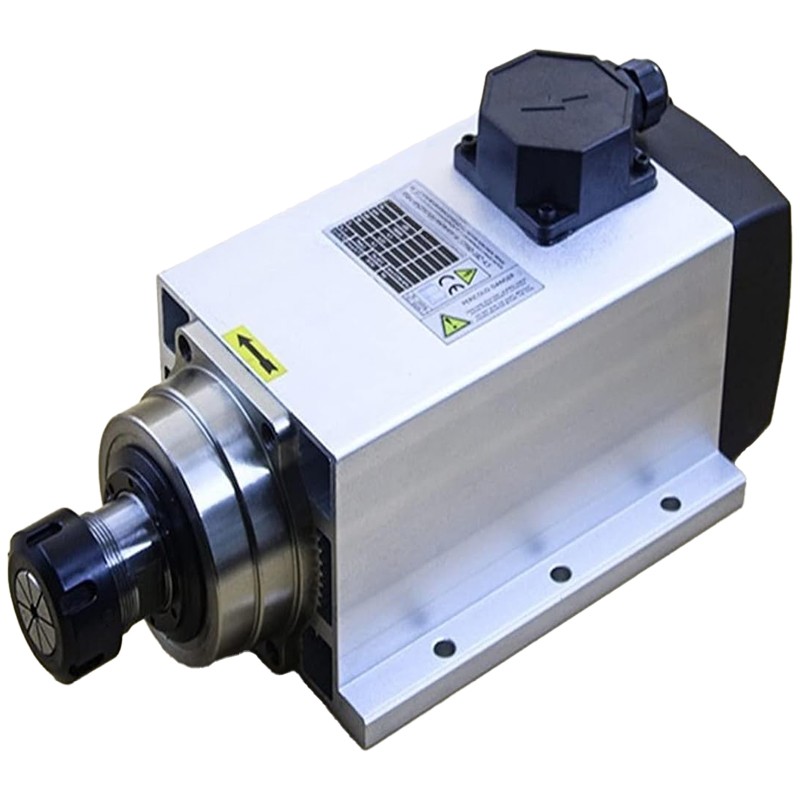

The HQD electrospindle with a power of 5.5 kW is a high-class device dedicated to work in advanced CNC systems. Thanks to the double shaft bearing on precise angular bearings, it ensures optimal stability and reliability, even with intensive axial loads. The spindle is factory-balanced, which guarantees quiet and stable operation.

High quality workmanship and reliability make HQD electrospindles an excellent choice for continuous operation in demanding conditions.

Key product features:

Application: The HQD 5.5 kW electrospindle is an ideal solution for CNC plotters, milling machines, engraving machines and deburring machines. Thanks to its reliability and durability, it is used both in industrial plants and in craft workshops.

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

The latest software for CNC milling machines UCanCam V12 Standard CAD/CAM, Polish language version

The only latest Ucancam V12 software available on the market translated into POLISH Ucancam V12 Standard software for milling plotters is a professional CAD and CAM solution. It is widely used in areas such as advertising, woodworking, decoration production, milling of complex forms (seals, ...More

The HQD electrospindle with a power of 5.5 kW is a high-class device dedicated to work in advanced CNC systems. Thanks to the double shaft bearing on precise angular bearings, it ensures optimal stability and reliability, even with intensive axial loads. The spindle is factory-balanced, which guarantees quiet and stable operation.