-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

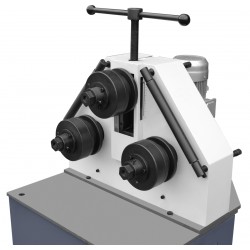

The CORMAK RBM40HV electric bending machine is designed for bending tubes, profiles, rods, and flat bars depending on the rollers used. The machine is equipped with a mechanical top roller adjustment with a vernier scale, making it ideal for bending arcs, circles, spirals, and other curved elements. Its heavy structure ensures excellent stability during operation. The included foot pedal allows convenient left/right drive control, and the machine can operate in both vertical and horizontal positions. Maximum bending capacity for tubes up to 50 mm. It is widely used in metal workshops and on construction sites.

Tube and Profile Bending Machine CORMAK RBM40HV – professional mandrel-free bender for vertical and horizontal operation

The CORMAK RBM40HV tube and profile bending machine is a precise, three-roller, mandrel-free bender designed for bending steel tubes, rectangular profiles, and solid materials. It enables operation in both vertical and horizontal positions, allowing flexible adaptation to production layouts. Equipped with hardened rolls and a scaled top roller adjustment system, it ensures repeatable bending radii and high wear resistance.

Main advantages of the machine

- Mandrel-free bending – enables bending of tubes and profiles without cross-section deformation.

- Vertical or horizontal operation – adaptable to workshop layout and technological needs.

- Mechanical top roller adjustment with vernier scale – ensures precise and repeatable bending radius settings.

- Heavy construction (485 kg) – guarantees stability and vibration-free performance during operation.

- Ground and hardened guide rollers – provide long service life and precise material guidance.

- Foot pedal control – convenient and safe operator control.

- Bidirectional bending – allows forming of complex curves and closed loop shapes.

Construction and technology

The CORMAK RBM40HV model has been designed for intensive use in industrial environments. The frame is built from thick, rigid steel elements, ensuring resistance to torsion and bending forces. Bending rollers are made of hardened, precision-ground steel with a 40 mm diameter, offering excellent wear resistance. The pressure adjustment system with vernier scale allows precise repetition of bending radii for serial production.

Precision and performance

The CORMAK RBM40HV tube and profile bender provides high bending accuracy for both single-piece and series production. The gear transmission with 2.2 kW motor (S6) enables smooth bending of hard materials, such as steel tubes with 2 mm wall thickness. Bidirectional rotation allows easy forming of closed arcs and spiral structures.

Applications

The RBM40HV model is a professional tool for the metal industry, dedicated to bending materials of various cross-sections. Ideal for:

- manufacturing railings, handrails, canopies, and structural components,

- workshops processing steel tubes and profiles,

- metalworking shops producing decorative architectural elements,

- serial production of precision-bent components.

Standard equipment

- Side guide rollers

- Foot pedal control

- Set of working rollers

- User manual

- CE declaration of conformity

Technical data

| Material: round tube [mm] |

50 × 2 |

| Material: square profile [mm] |

50 × 50 × 2 |

| Material: round bar [mm] |

35 |

| Material: solid rectangular bar [mm] |

35 × 35 |

| Roller diameter [mm] |

40 |

| Motor power [kW] |

S1 1.5 / S6 2.2 |

| Power supply |

3-phase, 400 V |

| Dimensions (L × W × H) [mm] |

900 × 850 × 1,700 |

| Weight [kg] |

485 |

Choose precision bending without compromise – opt for the CORMAK RBM40HV mandrel-free bender and ensure the highest quality and repeatability in your production. Contact our technical team to explore the full range of CORMAK three-roller bending machines.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

2 other products in the same category:

Write your review

* Required fields

I accept privacy policy rules