The basket is empty.

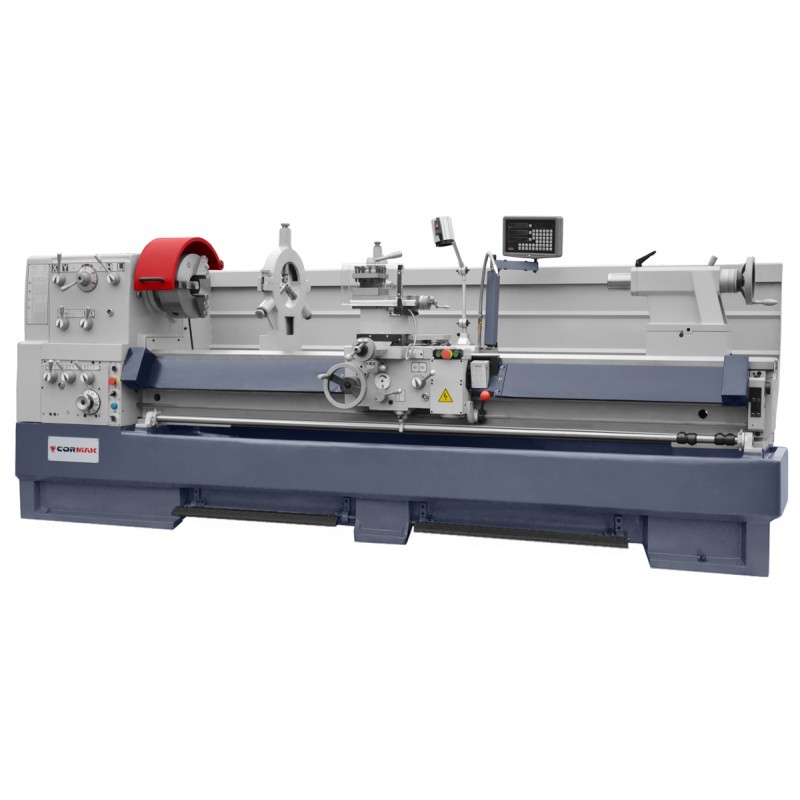

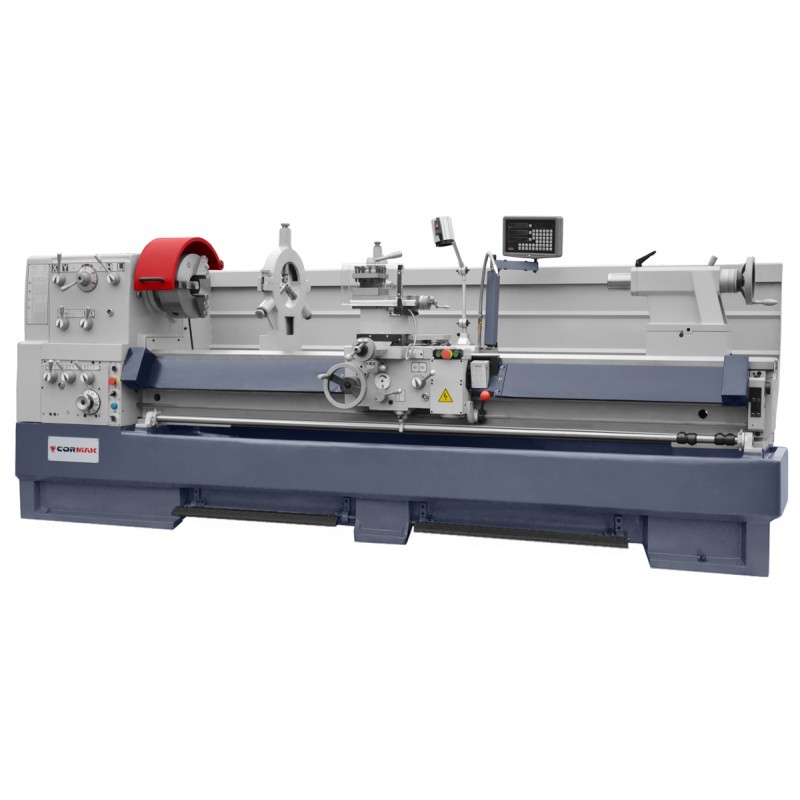

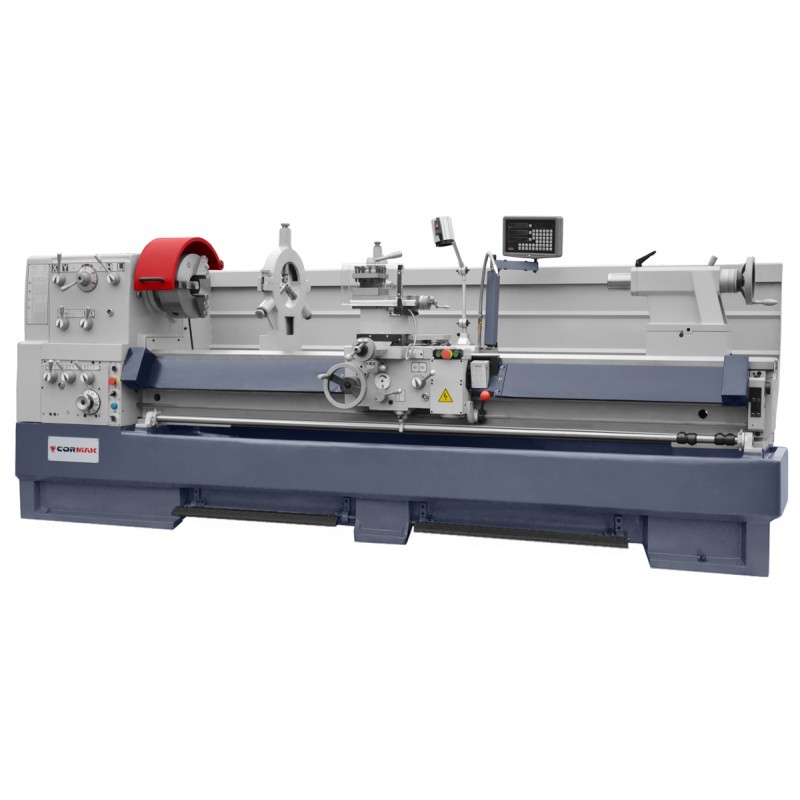

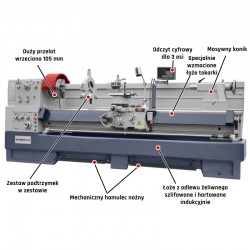

The 660 series metal lathes are equipped with fast feeds, a multi-plate clutch and digital readouts. Thanks to the latest solutions and equipment, the lathe is ideal for professional and industrial work.

| Turning diameter over bed | Ф660 mm |

| Turning diameter over the slide | Ф455 mm |

| Turning diameter after removing the bridge: diameter x width | 885 x 170 mm |

| Canine height | 330mm |

| Distance between canines | 4000mm |

| Bed width | 400mm |

| Max. cross-section of the cutting tool | 25 x 25 mm |

| Total travel of the transverse slide | 355 (0.05) mm |

| Total travel of the upper slide | 140 (0.02) mm |

| Headstock | |

| Spindle diameter | Ф105mm |

| Spindle tip | D1-8 |

| Number of spindle speeds | (12) 25-1500 rpm. |

| Spindle speed range | 25, 35, 55, 75, 115, 170, 325, 475, 660, 1000, 1500 rpm. |

| Thread and feed | |

| Lead screw diameter and thread | Ф40 x 6 mm |

| Inch thread pitches | 2-112 TPI (60 pcs.) |

| Metric thread pitches | 0.2-14 mm (47 pcs.) |

| DP thread | 4-112 DP (50 pcs.) |

| Modular threads | 0.1-7M.P. (39 pcs) |

| Longitudinal feed | 0.059-1.646 mm/rev. (35 pcs) |

| Cross feed | 0.020-0.573 mm (35 pcs) |

| Lathe tailstock | |

| Total travel of the tailstock sleeve | 180mm |

| Tailstock sleeve diameter | Ф 75 mm |

| Tailstock cone | MK-5 |

| Engine | |

| S1/S6 spindle drive motor | 7.5/9 kW |

| S1/S6 coolant pump motor | 0.1/0.12 kW |

| Weight and dimensions | |

| Dimensions L/W/H | 4340 x 1150 x 1550 mm |

| Weight approx. | 4150kg ( ± 2%) |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Tokarka solidna, doskonała w dużych fabrykach produkcyjnych.

Tokarka sprawdza się świetnie w wymagających warunkach pracy.

Tokarka o dużej mocy, sprawdzona w intensywnej produkcji.

Tokarka bardzo precyzyjna, działa bezbłędnie.

Doskonała w dużych fabrykach, bardzo wydajna.

Tokarka niezawodna, idealna do masowej produkcji.

Tokarka świetnie sprawdza się w dużych produkcjach.

Tokarka o wysokiej precyzji, niezawodna w pracy.

Idealna do pracy w fabrykach, bardzo wydajna i stabilna.

GOLIATH 660x4000 Universal Lathe

Industrial metal lathe CORMAK GOLIAT 660 x 4000 mm - solid cast iron bed construction, equipped with a 12-speed gearbox with a powerful 7.5 kW / 400V induction motor - maximum torque, large spindle passage 105 mm . Recommended for turning hard steels, ...More

CORMAK 660x2000 universal lathe SLOW RPM

The CORMAK 660x2000 low-speed lathe is an advanced tool designed for industrial production of single parts, where precision and quality of machining play a key role. This model is perfect for machining large and medium-sized parts, offering exceptional stability and accuracy, which are ...More

2022-10-12

Wydajna i precyzyjna

Tokarka idealna do produkcji seryjnej, bardzo wydajna.