- On sale!

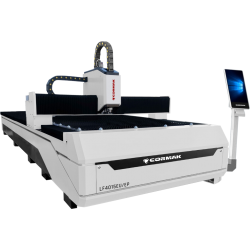

Fibre laser with a 1500x4000 mm working area. The EP version is equipped with YASKAWA servo motors and advanced nesting software. The laser cutting machine is DESIGNED and ASSEMBLED in POLAND. We configure our lasers according to each customer’s individual requirements.

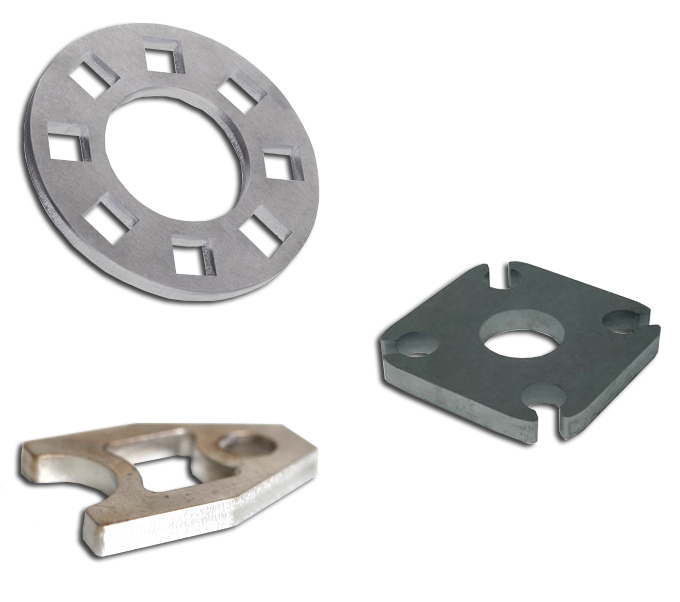

Fibre laser cutting machines are modern devices with numerous advantages. They are not only an excellent and much more cost-effective alternative to CO2 technology, but they also possess many features that help increase production efficiency (by up to 70%) and enhance quality. FIBER technology allows for cutting sheets and other materials of various thicknesses, from very thin to very thick. The wavelength in a FIBER laser is 1.064 micrometres, which provides an intensity 100 times greater than that of CO2 systems of comparable power.

MAIN ADVANTAGES OF THE LASER

Fibre laser

The control screen features a vertical display with a fast response time, higher contrast, wider viewing angle, low power consumption and high resolution. It also offers increased brightness, reduced reflectivity, and greater durability.

The bed structure features an internal honeycomb design, made of multiple welded rectangular tubes. Reinforcements inside the tubes increase the bed’s durability, rigidity and guide rail stability, effectively preventing deformation. High strength, stability and tensile resistance ensure up to 20 years of deformation-free use.

| WORKING AREA | 1500x4000 mm |

| POWER | 1000W, 1500W, 2000W, 3000W |

| REPEATABLE POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 40 m/min |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

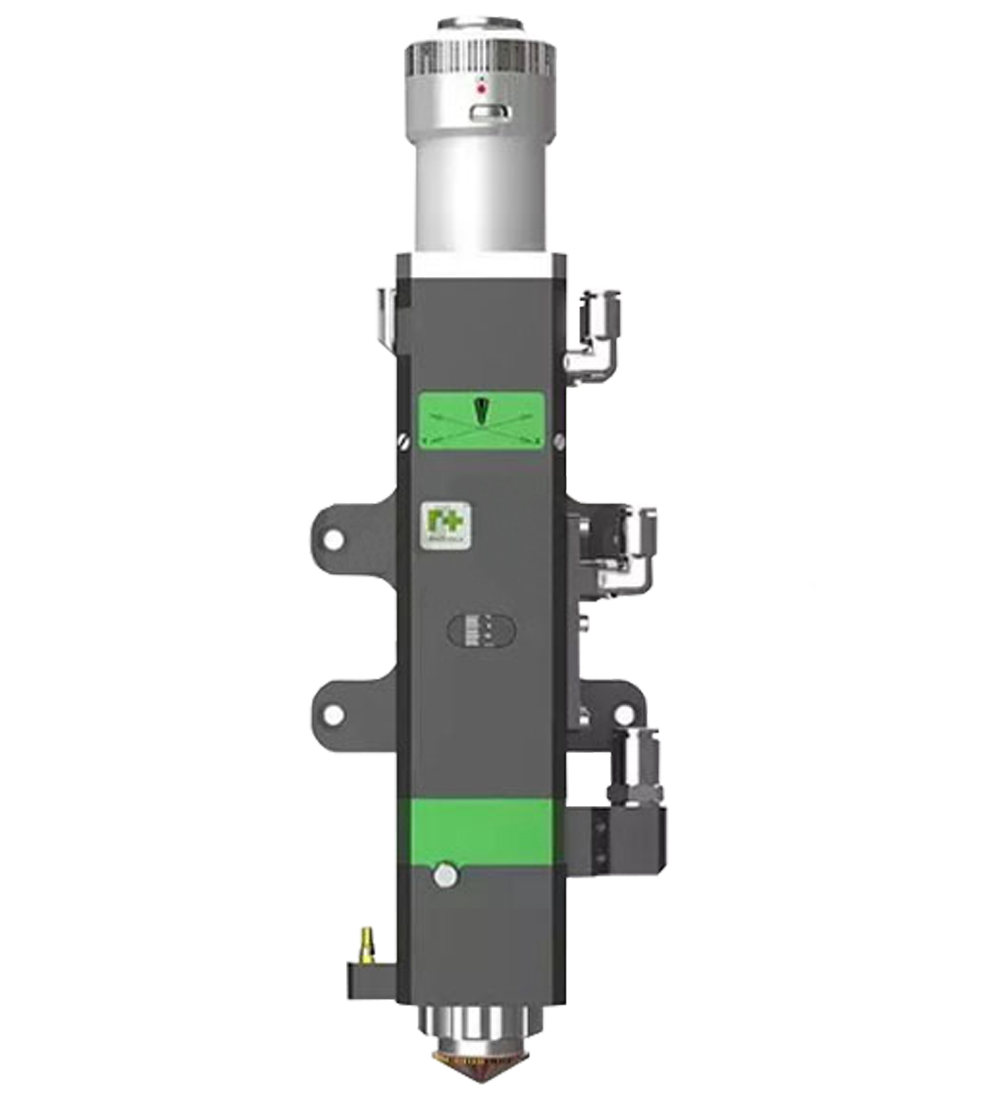

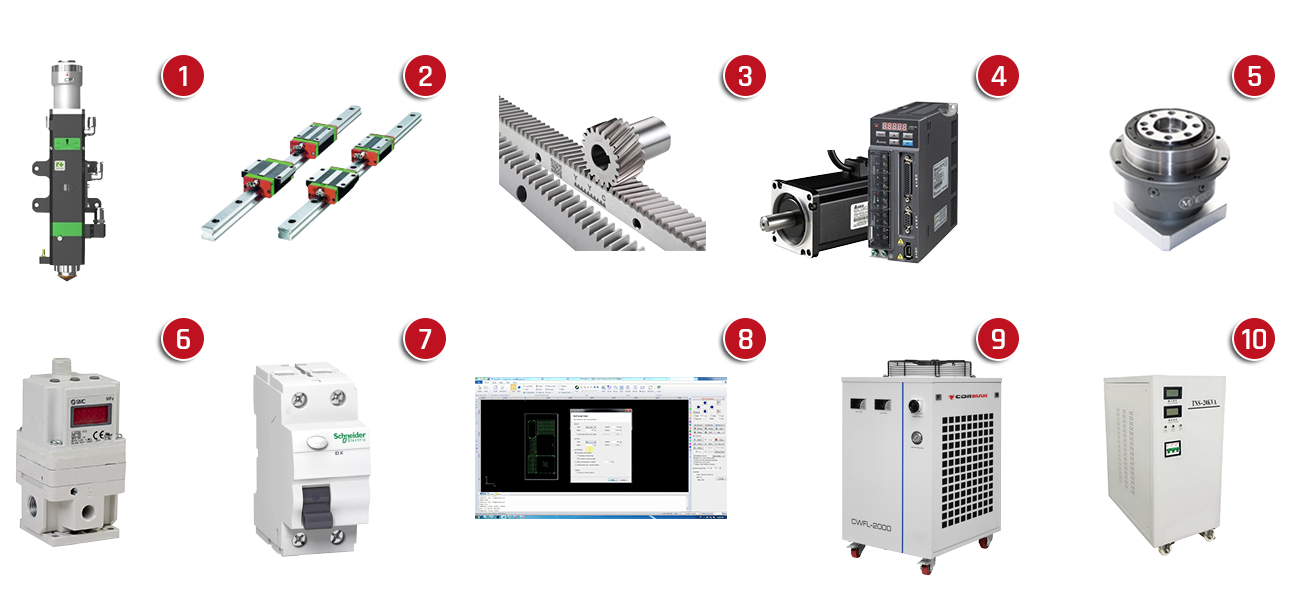

1. RAYTOOLS cutting head

2. HIWIN linear guides

3. YYC racks and pinions

4. DELTA servomotors

5. MOTOREDUCER gearbox

6. SMC pneumatic components

7. Electrical components such as contactors, relays and sensors from: Schneider, OMRON, IDEM

8. CypCut software

9. S&A water chiller

10. TNS voltage stabiliser

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Fibre Laser Cutter CORMAK FIBER LF4015EP4/EU/EP 1000W

Fibre laser with a 1500x4000 mm working area. The EP version is equipped with YASKAWA servo motors and advanced nesting software. The laser cutting machine is DESIGNED and ASSEMBLED in POLAND. We configure our lasers according to each customer’s individual requirements.

Fibre laser with a 1500x4000 mm working area. The EP version is equipped with YASKAWA servo motors and advanced nesting software. The laser cutting machine is DESIGNED and ASSEMBLED in POLAND. We configure our lasers according to each customer’s individual requirements.

Write your review

* Required fields

I accept privacy policy rules