- On sale!

FIBER laser cutter with a 1300×1300 mm working area. Thanks to its compact size, it is ideal for companies with limited production space. Laser cutter designed and assembled by CORMAK. Lasers are configured individually according to customer needs.

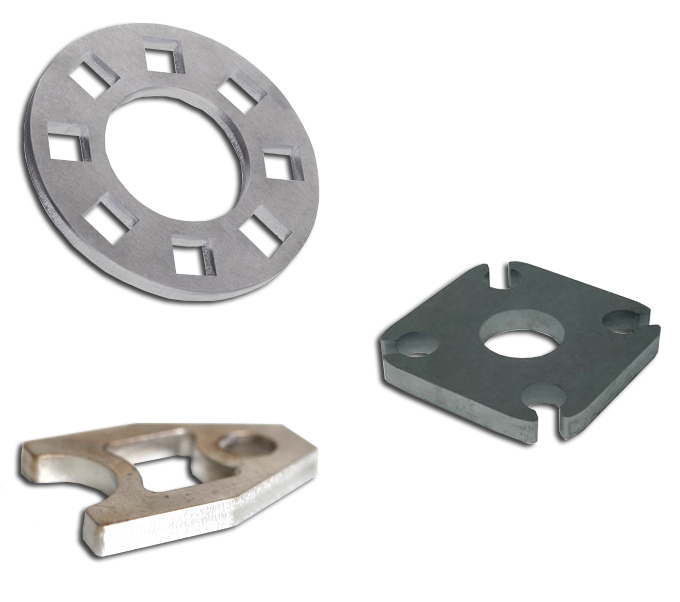

Fibre laser cutters are modern machines distinguished by numerous advantages. They are not only an excellent and far more cost-effective alternative to CO2 technology but also offer many benefits that enable up to 70% production growth and improved quality. FIBER technology allows cutting of sheets and other materials of various thicknesses — from very thin to very thick. The wavelength of the FIBER laser is 1.064 µm, providing intensity 100 times higher than that of CO2 systems of comparable power.

MAIN ADVANTAGES OF THE LASER

Fibre laser

The vertical display screen features fast response time, high contrast, wide viewing angle, low power consumption, and high resolution. It also offers excellent brightness, reduced reflection, and increased durability.

The bed structure has an internal honeycomb design made of multiple welded rectangular tubes. Reinforcements inside increase strength and improve the rigidity and stability of the guide rails, effectively preventing deformation. High strength, stability and tensile resistance ensure up to 20 years of use without distortion.

| WORKING AREA | 1300x1300 mm |

| POWER | 1000W (option*: 1500W, 2000W, 3000W) |

| REPEAT POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 40 m/min |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

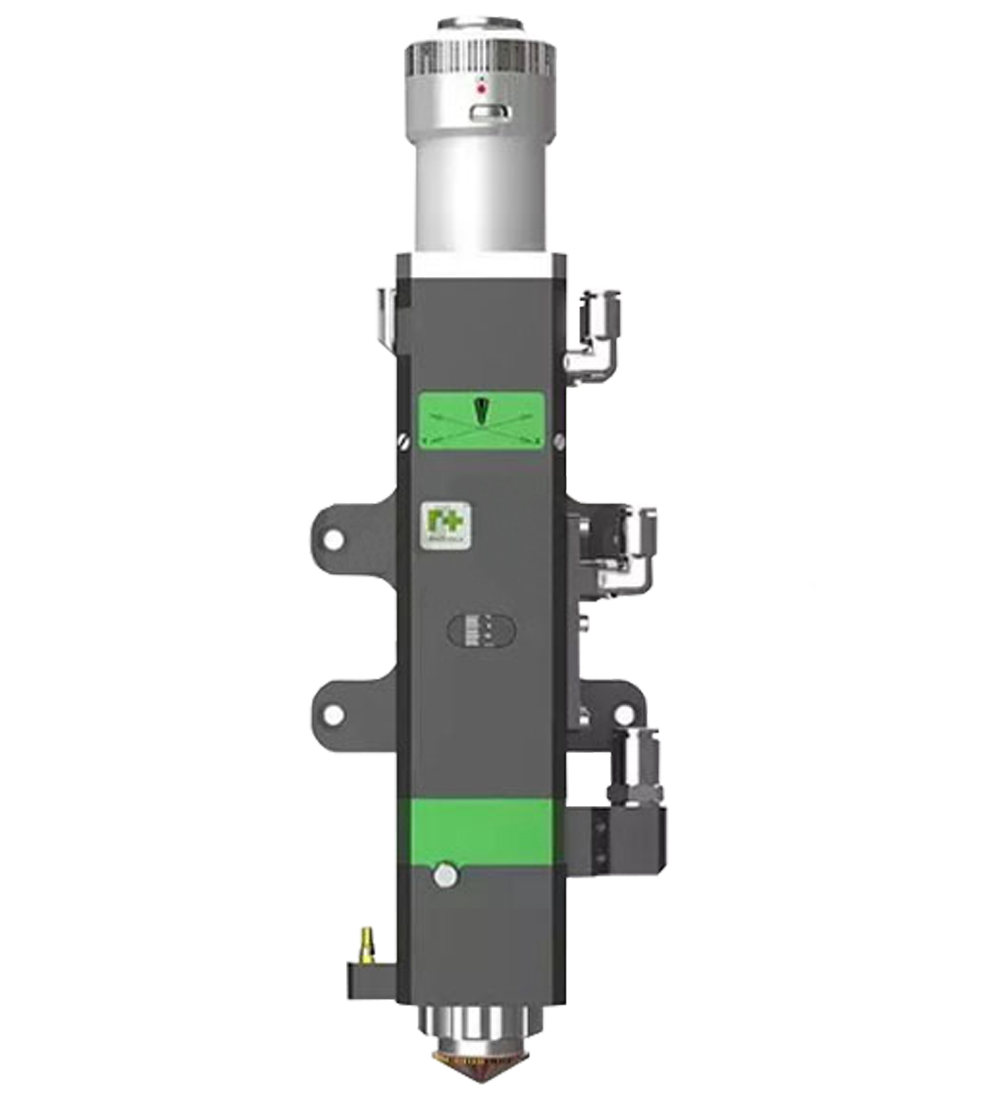

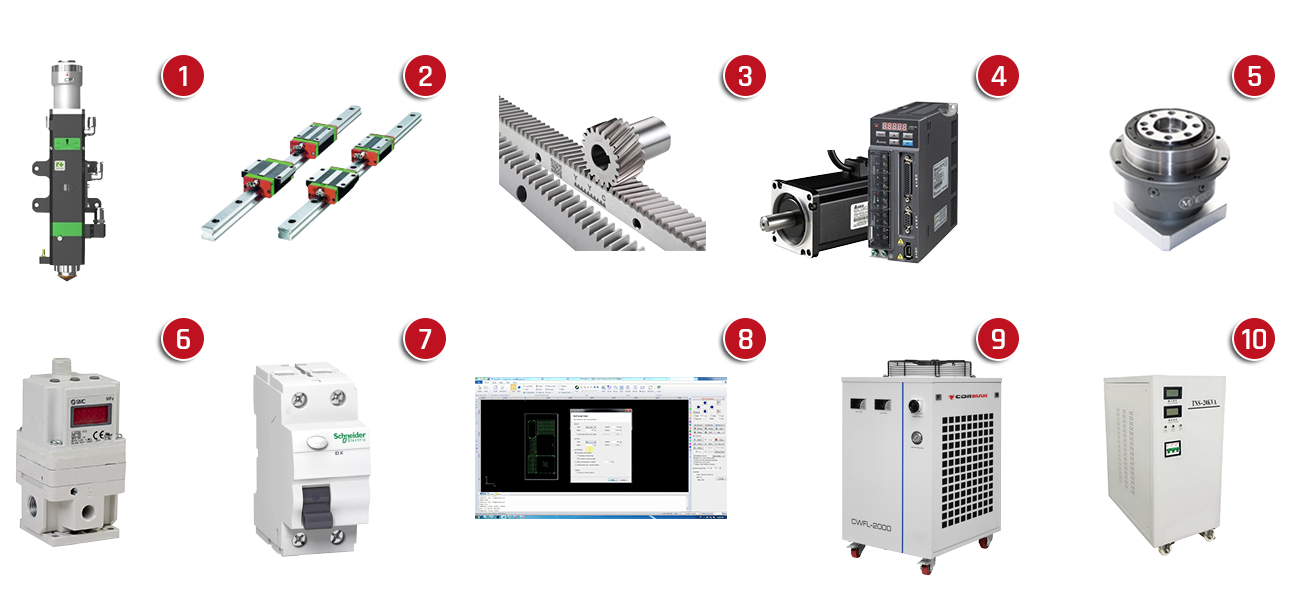

1. RAYTOOLS cutting head

2. Linear guides: HIWIN

3. Gears and racks: YYC

4. Servo motors: DELTA

5. Gear reducer: MOTOREDUCER

6. Pneumatic components: SMC

7. Electrical components such as contactors, relays, sensors: Schneider, OMRON, IDEM

8. CypCut software

9. Water chiller: S&A

10. Voltage stabiliser: TNS

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

It is possible to arrange professional training and machine commissioning carried out by a Cormak technician — this service is priced individually.

tabilizer

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

FIBER laser cutter with a 1300×1300 mm working area. Thanks to its compact size, it is ideal for companies with limited production space. Laser cutter designed and assembled by CORMAK. Lasers are configured individually according to customer needs.