The basket is empty.

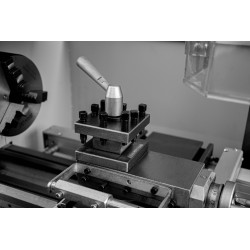

The TYTAN CENTER 750 Vario lathe-milling machine combines two machines in one, offering convenience and workspace efficiency. It features stepless spindle speed control for both lathe and milling functions. Turning: 250x750mm, 0.75kW/230V + Milling: 0.6kW/230V. Performs turning of internal and external cylindrical surfaces, threading and parting, as well as milling, slotting, drilling and reaming. Designed for small industrial plants, workshops and garages.

The machine’s design combines two devices – a lathe and a milling machine. Each unit has its own motor with stepless speed control, significantly reducing setup and calibration time. The lathe-milling combination is suitable for producing complex parts without reinstallation on another machine – improving machining time and overall productivity. It can perform a wide range of operations, from sharpening and slot milling to off-centre and angled drilling.

SET INCLUDES 12 x 12 mm TURNING TOOLS – 11 PCS |

|

| LATHE | |

| Max. swing over bed | 250 mm |

| Swing over cross slide | 150 mm |

| Centre distance | 750 mm |

| Bed width | 135 mm |

| Spindle bore | 29 mm |

| Spindle taper | MT4 |

| Spindle speed control | Stepless (2 ranges) |

| Spindle speed | 50–1125 | 100–2250 rpm |

| Metric threads | (18) 0.2–3.5 mm/rev |

| Inch threads | (21) 8–56 TPI |

| Longitudinal feeds | (6) 0.07–0.4 mm/rev |

| Top slide travel | 70 mm |

| Cross slide travel | 130 mm |

| Longitudinal travel | 630 mm |

| Tailstock sleeve diameter | 30 mm |

| Tailstock travel | 70 mm |

| Tailstock taper | MT2 |

| Chuck size | 125 mm |

| Motor power / supply voltage S1/S6 | 0.75/0.9 kW / 230 V |

| Tool size | 12 x 12 mm |

| MILLING MACHINE | |

| Max. drilling capacity | 13 mm |

| Max. end mill diameter | 13 mm |

| Max. face mill diameter | 50 mm |

| Spindle taper | MT2 |

| Spindle quill travel | 50 mm |

| Spindle-to-table distance | 43–250 mm |

| Spindle-to-column distance | 170 mm |

| Head tilt | ±90° |

| Spindle speed range | 50–2250 rpm |

| T-slots (number and size) | 8 mm / 2 |

| Motor power / supply voltage | 0.6 kW / 230 V |

| GENERAL DATA | |

| Machine dimensions (L/W/H) | 1350 x 580 x 1630 mm |

| Weight | 230 kg |

|

|

|

|

|

|

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Tailstock Turret Head MK4 is a practical accessory for lathes, designed for repetitive operations requiring multiple tools. It allows quick tool changes directly in the tailstock without the need for retooling, significantly increasing efficiency and precision in turning processes. ...More

Lathe-Milling Combination Machine CORMAK AT320 with Tool Set and Live Centre

Lathe-milling machine AT-320 combines two machines in one, offering convenience and workspace efficiency. The lathe features a 12-speed gearbox driven by an induction motor 1.5kW/230V , while the milling unit is equipped with a 4-speed gearbox and 0.55kW/230V motor. Performs turning ...More

Lathe-Milling Combination Machine CORMAK TYTAN Center 750 Vario with Tool Set and Live Centre

The TYTAN CENTER 750 Vario lathe-milling machine combines two machines in one, providing convenience and workspace efficiency. It features smooth spindle speed control for both turning and milling functions. Turning: 250x750mm, 0.75kW/230V + Milling: 0.6kW/230V. Performs turning of external ...More

Write your review

* Required fields

I accept privacy policy rules