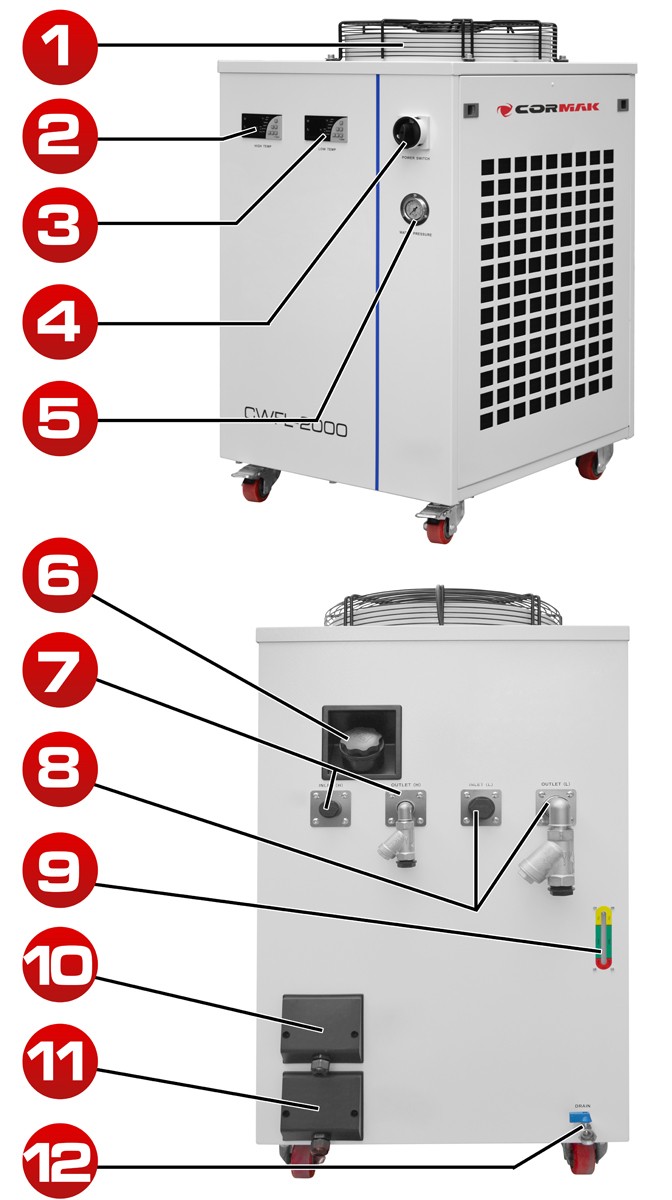

Chiller CORMAK CWFL-1500 for FIBER Laser Cutter

The unit features two independent cooling systems: one for the laser head and one for the laser source. Chiller designed for lasers up to 1500 W. It cools the laser source in FIBER laser cutters using a refrigeration compressor, maintaining the proper operating temperature of the source and ...More

Write your review

* Required fields

I accept privacy policy rules