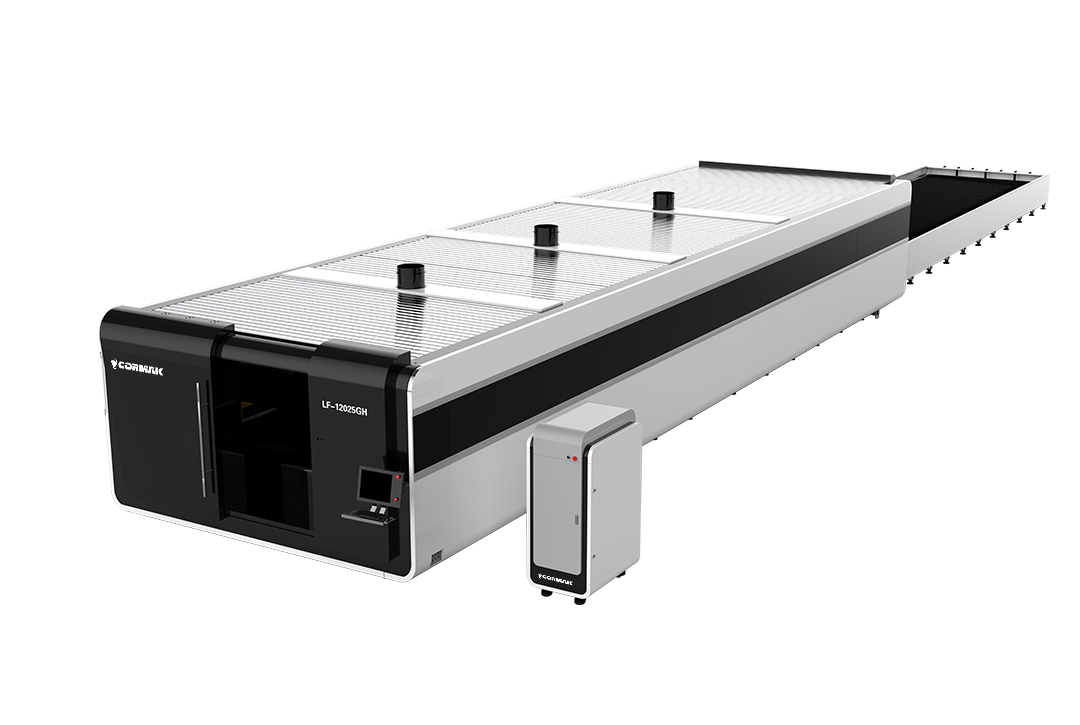

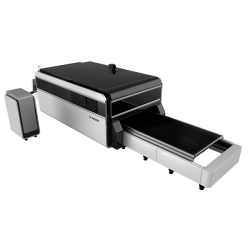

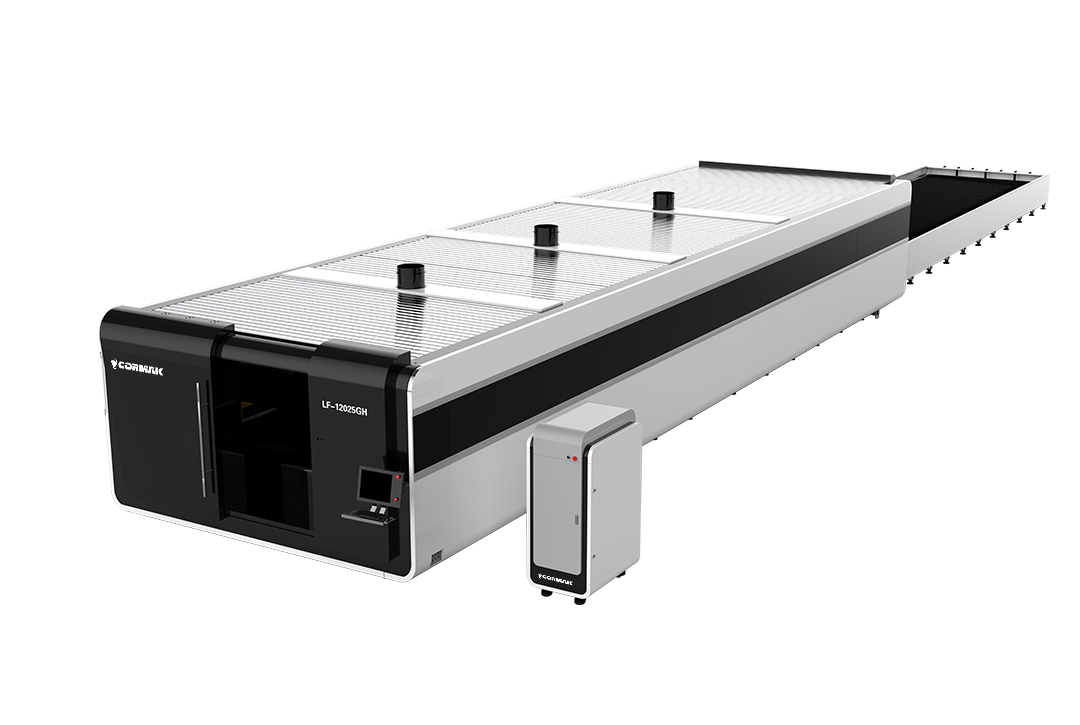

Fiber optics laser cutters constitute modern devices with many advantages. These are not only a perfect and more profitable alternative to the CO2 technology, but they also possess a lot of pros by themselves, such as improving the production by considerable margin and increasing its quality. FIBER technology allows for cutting sheets and other materials of various thickness: from very thin to very thick. The length of a wave in a FIBER laser is 1.064 micrometre long. These properties influence the intensity, which is a hundred times higher than in the case of CO2 devices of similar power.

The biggest advantages of the laser are

- failure-free optical fiber cable

- no elements that wear out

- the source of the fiber optic laser takes 1/3 less space

- high energetic efficiency - 100000 hours of work

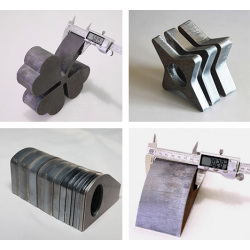

- universal applicability (specific metal sheets, carbon and stainless steel, copper, brass, aluminium, titanium)

Optical fiber laser

- increases the efficiency by 80%

- reduces the handling costs by 70%

- saves 80% of energy

- minimises the consumption of gas

- saves space in the workplace by 30%

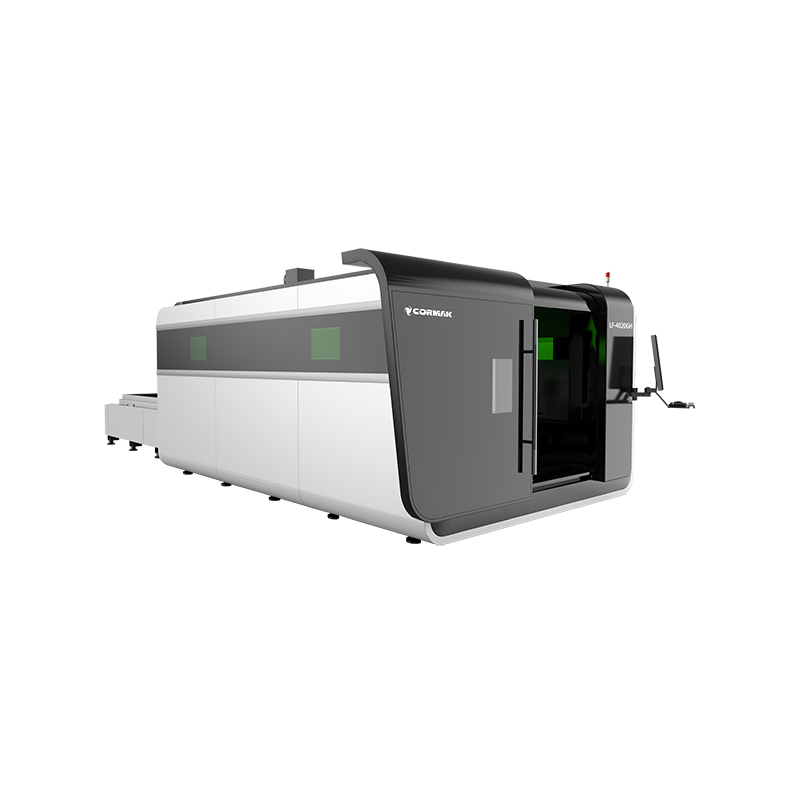

Safety and no pollution

Safety and no pollution

- Fully built-on laser

- Observational window with a laser protective glass compliant with the European CE marking

- The smoke produced by cutting can be filtered internally, and not pollute environment

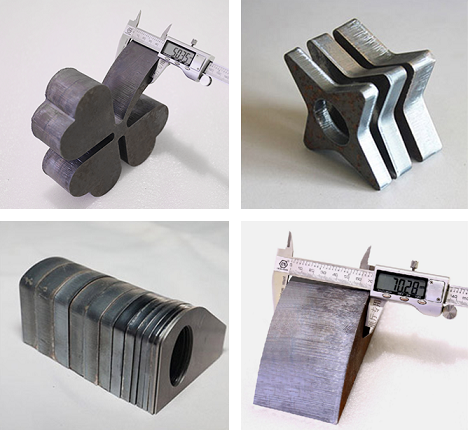

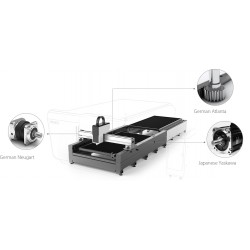

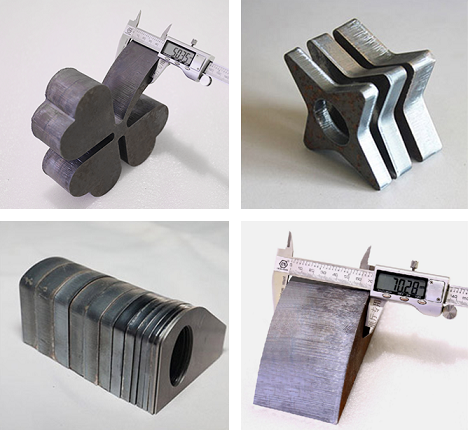

Sliding gate made of annealed aircraft aluminium

The construction of the sliding gate is made of annealed aircraft aluminium, formed with a strength of 4300 tonnes, achieving unprecedented rigidity. Aircraft aluminium has many advantages: high rigidity (higher than cast iron), small mass, resistance to corrosion and oxidation as well as susceptibility to machining.

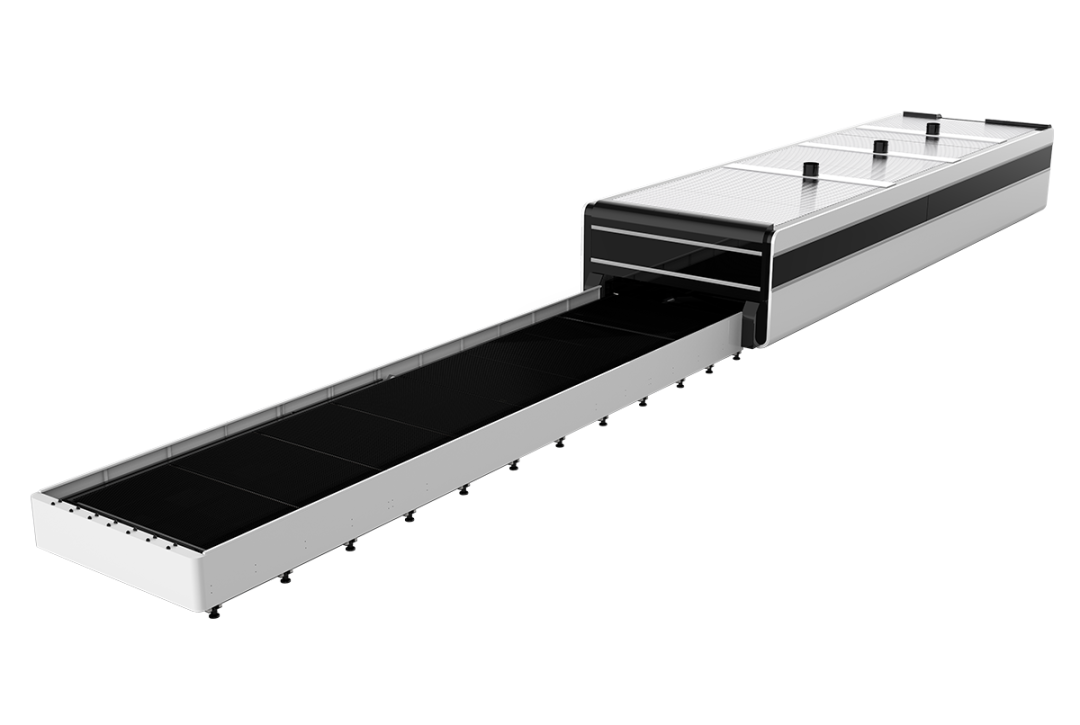

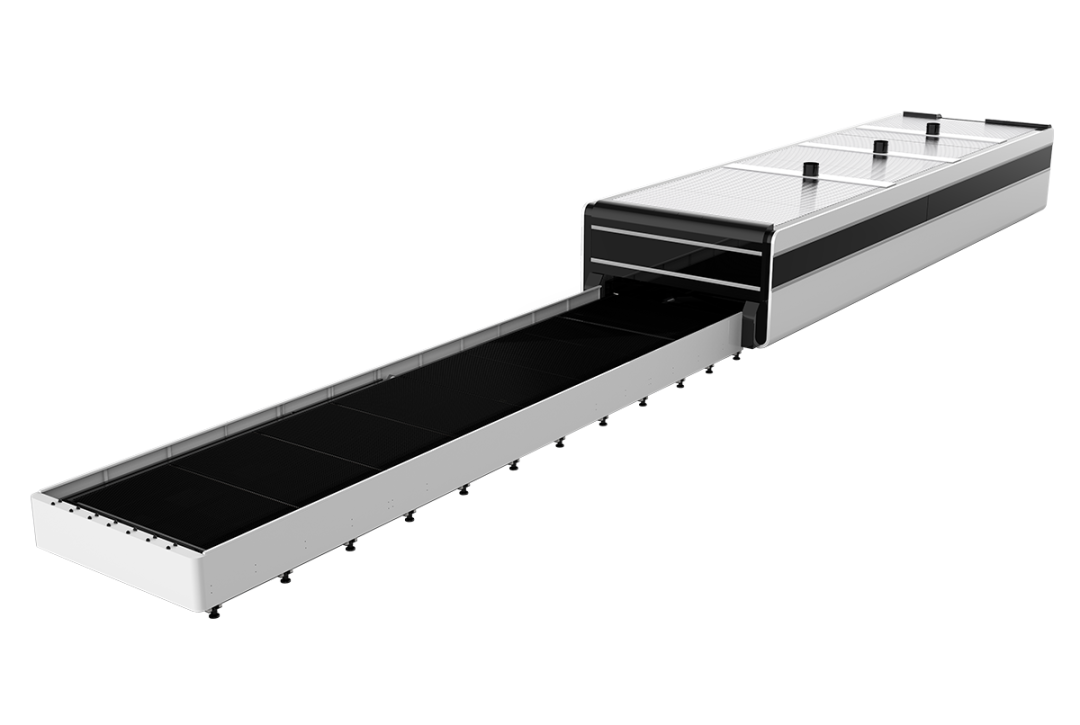

Replaceable working table

The removable work table consists of an upper and lower platform, the movement and replacement of which are controlled by the controller. The scherzt machine is able to implement the platform exchange within 15 seconds.

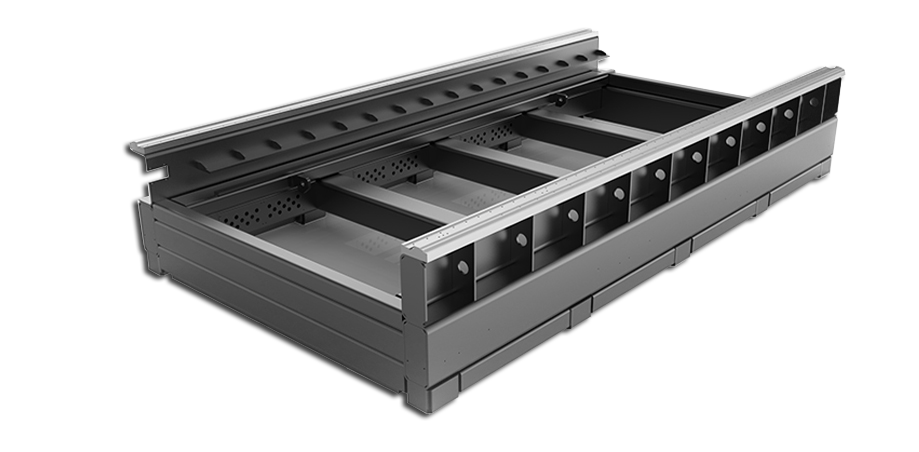

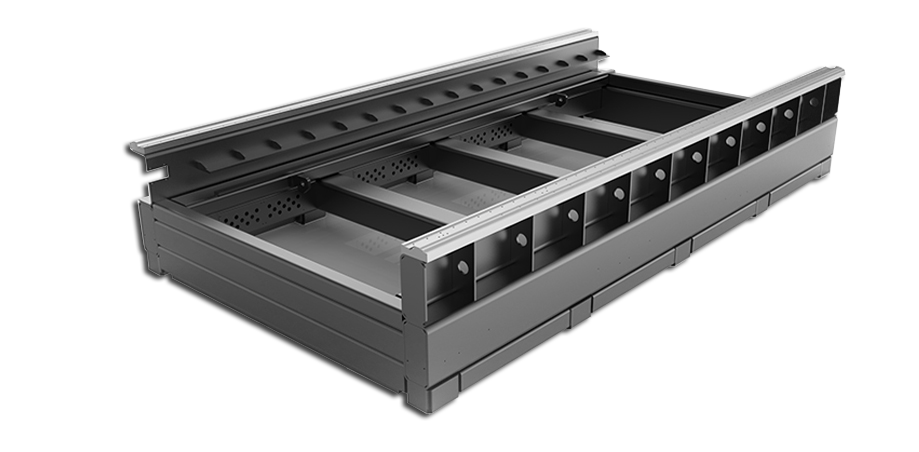

Bed welded using rectangular profiles

The inner structure of the bed forms a metal cell structure similar to a honeycomb patch, which is welded multiple rectangular tubes. Inside these tubes are stiffeners, which improve the durability and the stretching durability and stability of the guide rail, in order to avoid the deformation of the bed.

- High durability, stability, stretching durability, amounting to 20 years of usage without deformations

- The thickness of the rectangular sheet of a tube is 10 mm and 4500 kg

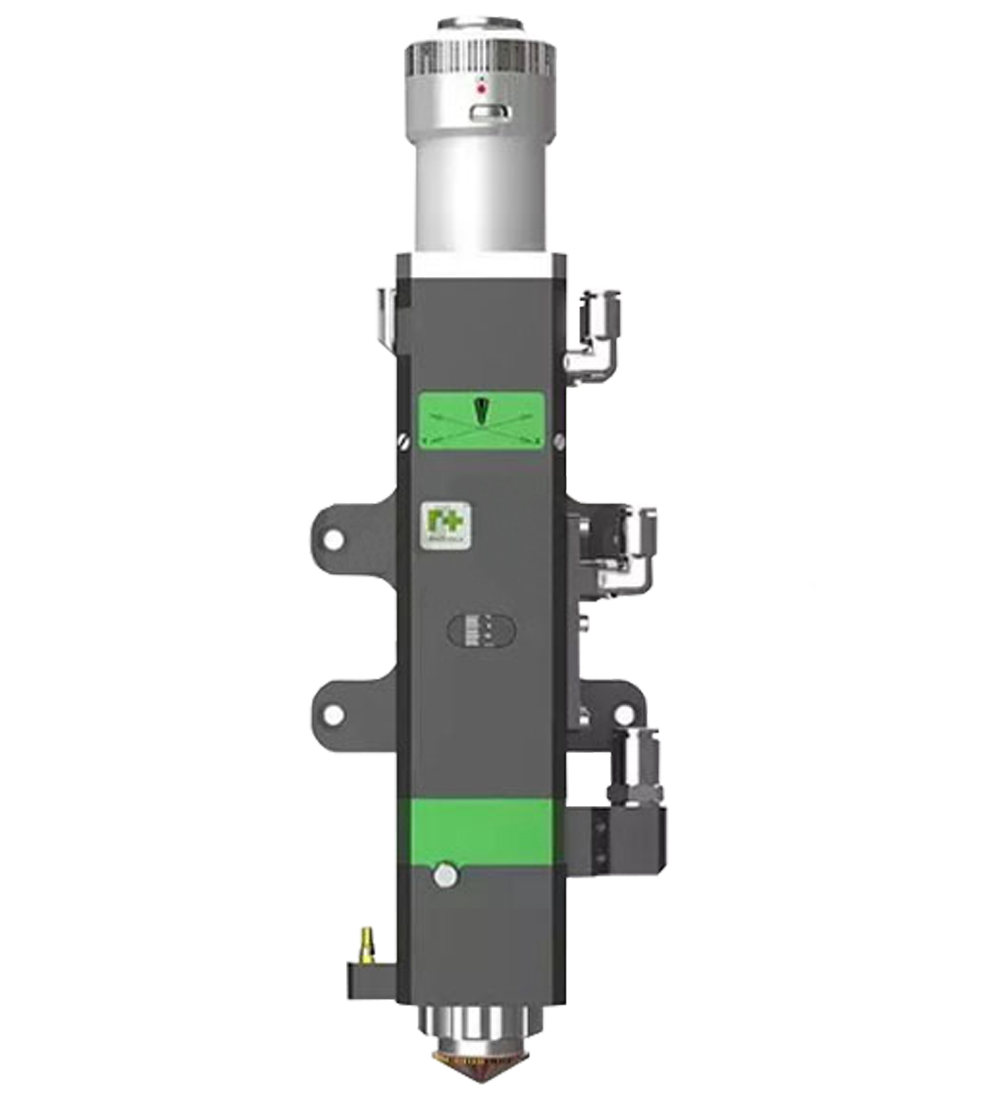

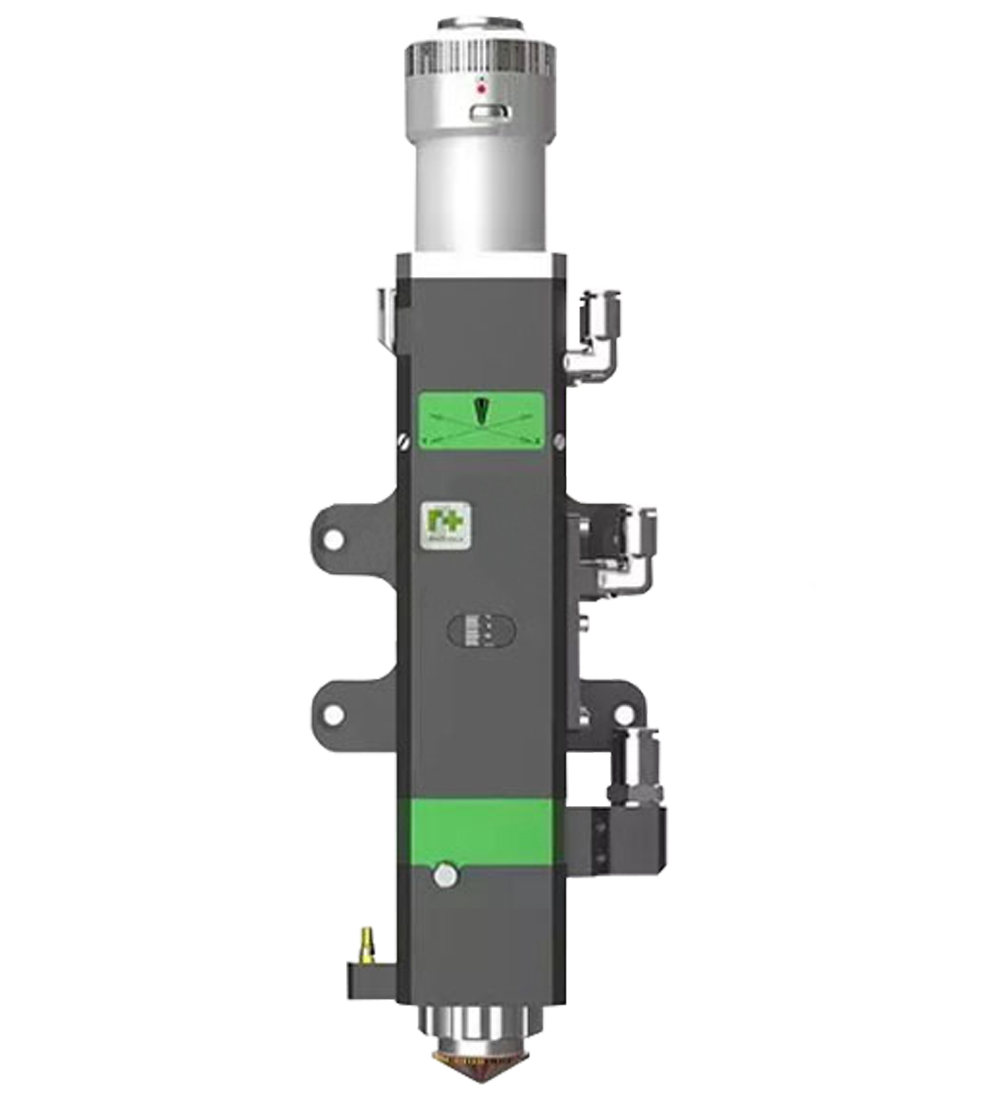

RayTools head

-

Automatic focus regulation – Autofocus – The software automatically regulates the focusing lens during cutting metal sheets of various thickness. The speed of automatic focus regulation is 10 times higher than the speed of manual regulation.

-

Greater range of manual regulation – The range of regulation -10mm - + 10 mm, precision of 0.01 mm is useful in when it comes to materials of different thickness (0–20 mm) – Below 1500W.

-

Long durability. Collimating lenses and converging lenses possess a heat sink which cools down water, in turn decreasing the temperature of a cutting head, in order to improve the durability of the cutting head.

Fiber laser 20 kW IPG

IPG YLS-CUT series high power laser source, the thickness of stainless steel, aluminum and other materials can reach 70mm.

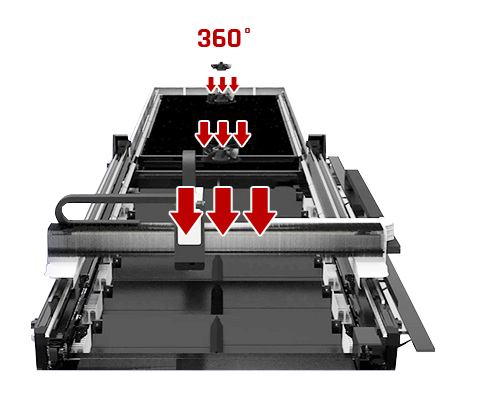

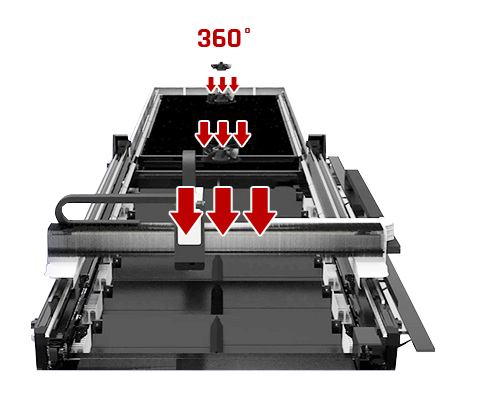

Segmented smoke extraction

The laser is equipped with a modern smoke extraction system. Each section of the bed has a fan that absorbs smoke and dust from all directions under high pressure. Strong adsorption effectively cleans the air, protecting the lens from contamination.

Quick linear motors

Laser cutters with linear motors allow for a quick and efficient cutting out of the shapes from metal sheets. Exceptionally high speed and acceleration without the need of limiting pick-up, joined with high resolution measurement systems ensure achieving great cutting efficiency and accuracy.

Linear motor is an electric motor, which transforms electric energy directly into mechanical energy of progressive movement. The basic advantages resulting from this technology of linear motors is minimising friction, absence of wiggling, absence of gears generating losses of energy and absence of positioning errors. In terms of efficiency, the most important feature of linear motors is the ability to achieve work of high dynamic.

Installing linear motors in all axes ensures maintaining work parameters through the whole period of using the machine. These motors do not wear out and do not require maintenance – they are failure-free.

Technical data

|

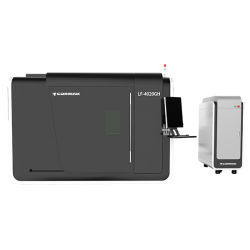

LF4020GH |

LF6025GH |

| Working area |

4000x2000mm |

6000x2500mm |

| Power |

20000W |

| Accuracy |

±0.02 mm/m |

| Maximum speed |

200 m/min |

| Maximum acceleration |

4G |

| Power supply |

400V 50Hz |

| Dimensions |

11475x2574x5169 |

14937x3952x2287

|

Safety and no pollution

Safety and no pollution

Write your review

* Required fields

I accept privacy policy rules