-

-

Instructions in Polish

-

Service

-

Warranty 12/24 months

-

Delivery

Free

Universal Tool & Cutter Grinder CORMAK TS-125 – versatile sharpener for drills, end mills and lathe tools

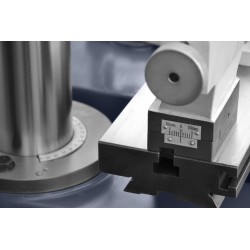

CORMAK TS-125 is a precise tool and cutter grinder designed for comprehensive sharpening and reconditioning of cutting tools. It enables the processing of twist drills, cylindrical milling cutters, lathe tools and many other cutting instruments. Its solid construction, wide range of adjustments and extensive standard equipment make it a machine built for intensive use in industrial plants, tool rooms and maintenance departments.

Main advantages of the machine

- Universal application – grinding of twist drills, milling cutters, lathe tools and cylindrical surfaces.

- Precise adjustment – swivelling head in two planes: +40°/-40° vertically and +50°/-50° horizontally.

- Stable construction – heavy base efficiently damping vibrations, ensuring high grinding quality.

- Drive unit with 3-jaw chuck (Ø80 mm) – allows machining of cylindrical and rotating parts.

- Drill sharpening range: Ø5–32 mm – ideal for most tools used in industry.

- Longitudinal travel 320 mm and cross travel 170 mm – large working range with compact machine dimensions.

- Complete standard equipment – ready for operation with various tool types without additional accessories.

Design and technology

The CORMAK TS-125 tool grinder has been designed for maximum stability and structural rigidity. The worktable measuring 535 × 130 mm with precision guides ensures smooth movement in both axes. The grinding head, driven by a 0.18 kW motor at 2800 rpm, can be set in two planes, allowing grinding at any angle. Thanks to holders and arbors of different diameters, precise clamping of various tool types is possible.

Precision and work efficiency

The machine provides high repeatability and precision of sharpening, even during serial production and intensive use. The precise geometry of the slides, high-quality components and the supplied set of grinding wheels (including cup and diamond wheels) ensure tool edges of excellent surface finish. Milling cutter grinder and drill sharpener in one body – a solution that eliminates the need for investing in multiple separate machines.

Applications

The TS-125 model is suitable for:

- tool rooms and production plants engaged in the manufacturing and re-grinding of cutting tools,

- mechanical and locksmith workshops,

- maintenance departments of large industrial facilities,

- technical schools teaching grinding and sharpening technologies.

Standard equipment

- Stable base with integrated tool cabinet

- 2 centres for setting the workpieces

- Table movement limiters – precise control of travel range

- 2 standard 60° centres and 2 half-centres 60°

- 3 grinding wheels: cup 125 × 45 × 32 mm, diamond 125 × 32 × 32 mm, standard 125 × 25 × 32 mm

- Grinding plate

- Drive unit with 3-jaw chuck (Ø80 mm)

- Attachment for twist drill sharpening

- Lathe tool holder

- Arbors for milling cutters: Ø16, Ø22, Ø32 mm

- Diamond dressing stone

- Complete set of service tools

Technical data

| Maximum diameter of workpiece |

175 mm |

|---|

| Centre distance |

320 mm |

|---|

| Table size |

535 × 130 mm |

|---|

| Longitudinal table travel |

320 mm |

|---|

| Cross table travel |

170 mm |

|---|

| Head – vertical swivel |

-40° to +40° |

|---|

| Head – horizontal swivel |

-50° to +50° |

|---|

| Grinding head speed |

2800 rpm |

|---|

| Motor power |

0.18 kW |

|---|

| Weight |

266 kg |

|---|

Invest in professional sharpening – choose CORMAK TS-125

CORMAK TS-125 is a robust and versatile tool and cutter grinder that replaces multiple separate machines. It serves perfectly as a drill sharpener, milling cutter grinder and lathe tool grinder. Choose reliability, precision and multifunctionality in one – order now and improve the quality of machining in your workshop.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

11 other products in the same category:

Write your review

* Required fields

I accept privacy policy rules