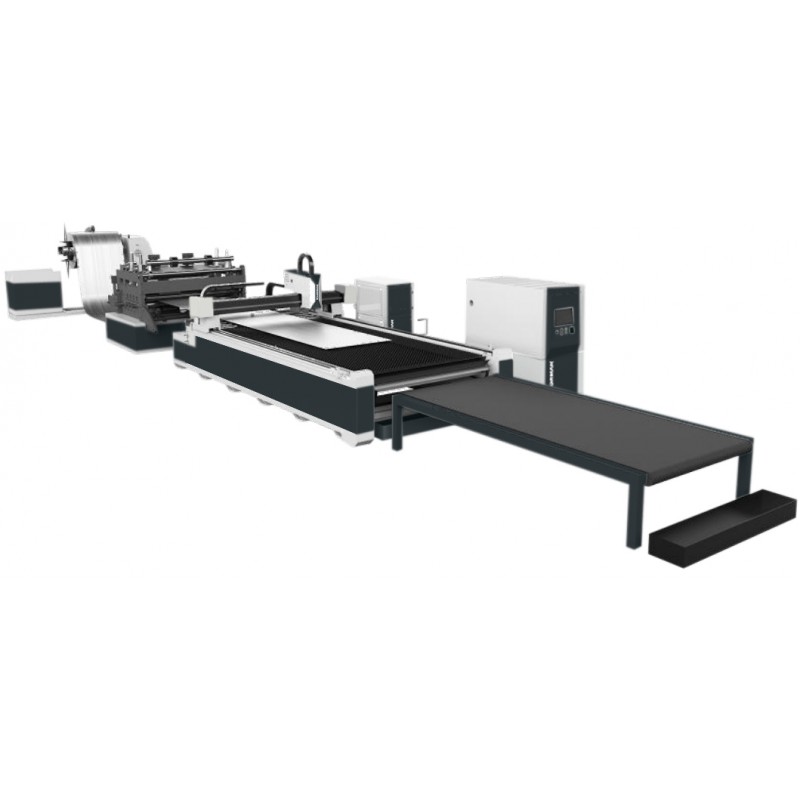

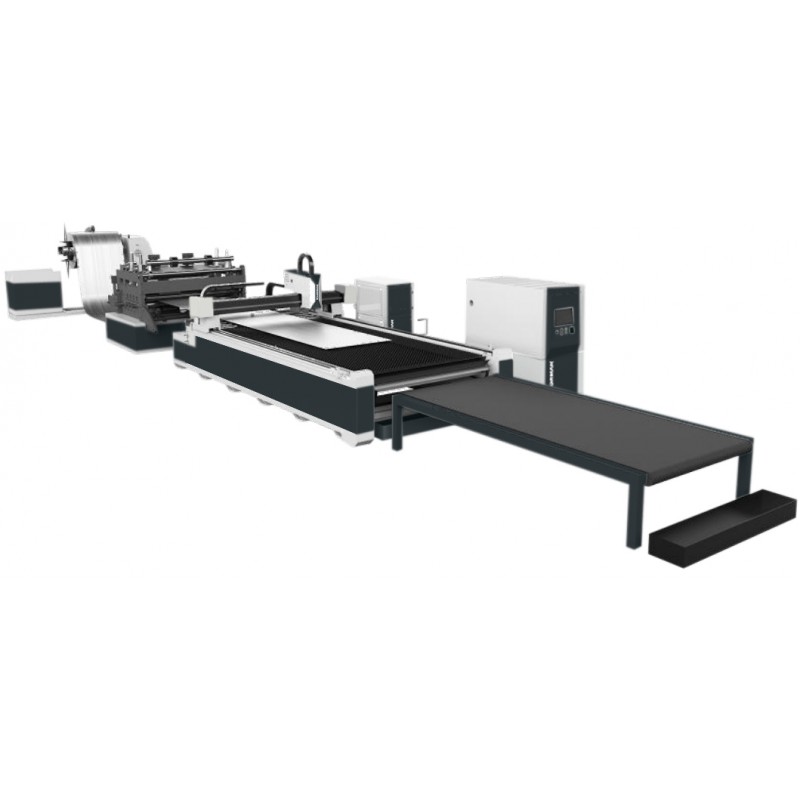

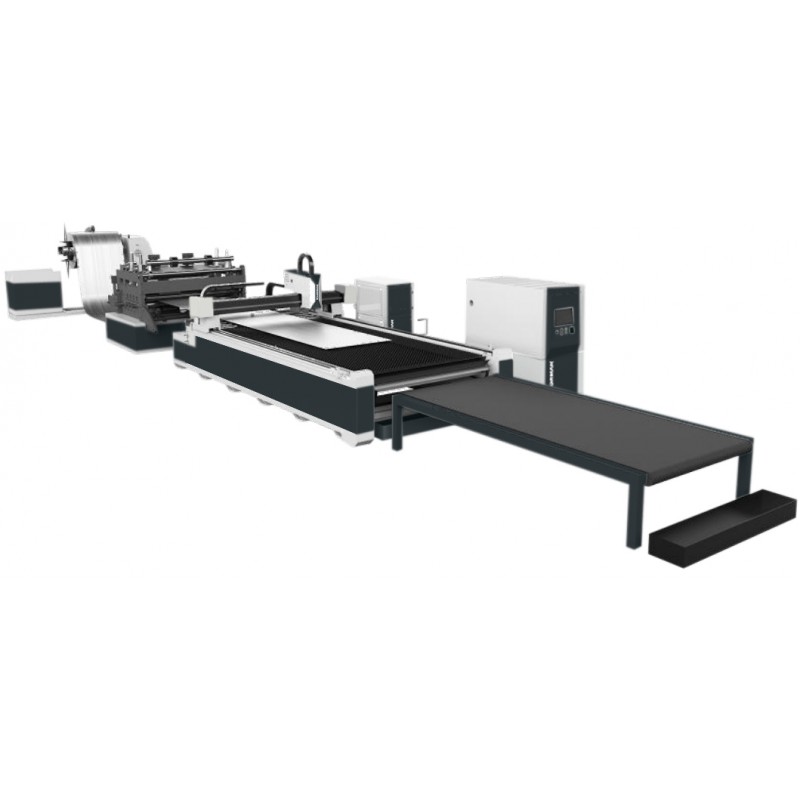

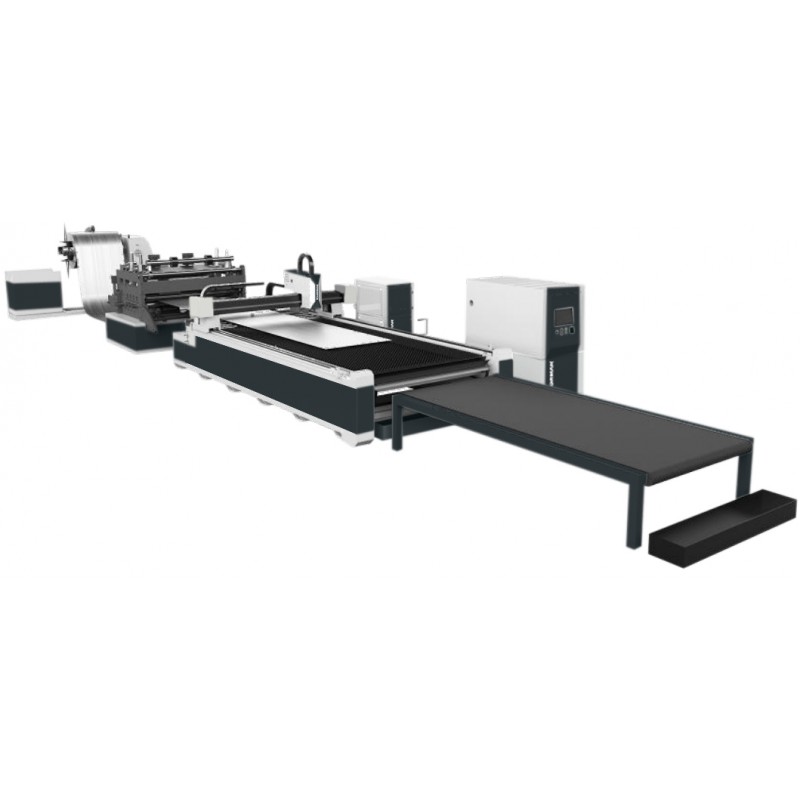

Specialized fiber laser with automatic sheet feeder. Cutting sheet metal from a steel coil. The laser cutter is also equipped with a vacuum holder that allows for automatic unloading of the finished product, which significantly saves time and improves efficiency. Cutting sheet metal from a coil is a technology that is becoming increasingly popular in the industry. .

Fiber laser cutters are modern devices that stand out with numerous advantages. They are not only an excellent and much more cost-effective alternative to CO2 technology, but also have many advantages in themselves, which allow for the development of production (up to 70%) and improvement of its quality. FIBER technology allows for cutting sheet metal and other materials of various thicknesses from very thin to very thick. The wavelength in the FIBER laser is 1.064 micrometers. These properties affect the intensity, which is 100 times greater than in the case of CO2 devices of similar power.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Laser cutting line from steel coil - FIBER LF3015RL sheet metal feeder

Specialized fiber laser with automatic sheet feeder. Cutting sheet metal from a steel coil. The laser cutter is also equipped with a vacuum holder that allows for automatic unloading of the finished product, which significantly saves time and improves efficiency. Cutting sheet metal from a coil is a technology that is becoming increasingly popular in the industry. .

FIBER LF3015GAL with automatic loading and unloading

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provides full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The offer includes a laser with a power from 1000W to 8000W, ...More

FIBER LF3015GALW Fiber laser with automatic storage system

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provides full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The offer includes a laser with a power from 1000W to 8000W, ...More

Specialized fiber laser with automatic sheet feeder. Cutting sheet metal from a steel coil. The laser cutter is also equipped with a vacuum holder that allows for automatic unloading of the finished product, which significantly saves time and improves efficiency. Cutting sheet metal from a coil is a technology that is becoming increasingly popular in the industry. .

Write your review

* Required fields

I accept privacy policy rules