The basket is empty.

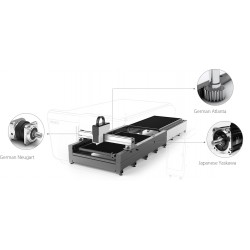

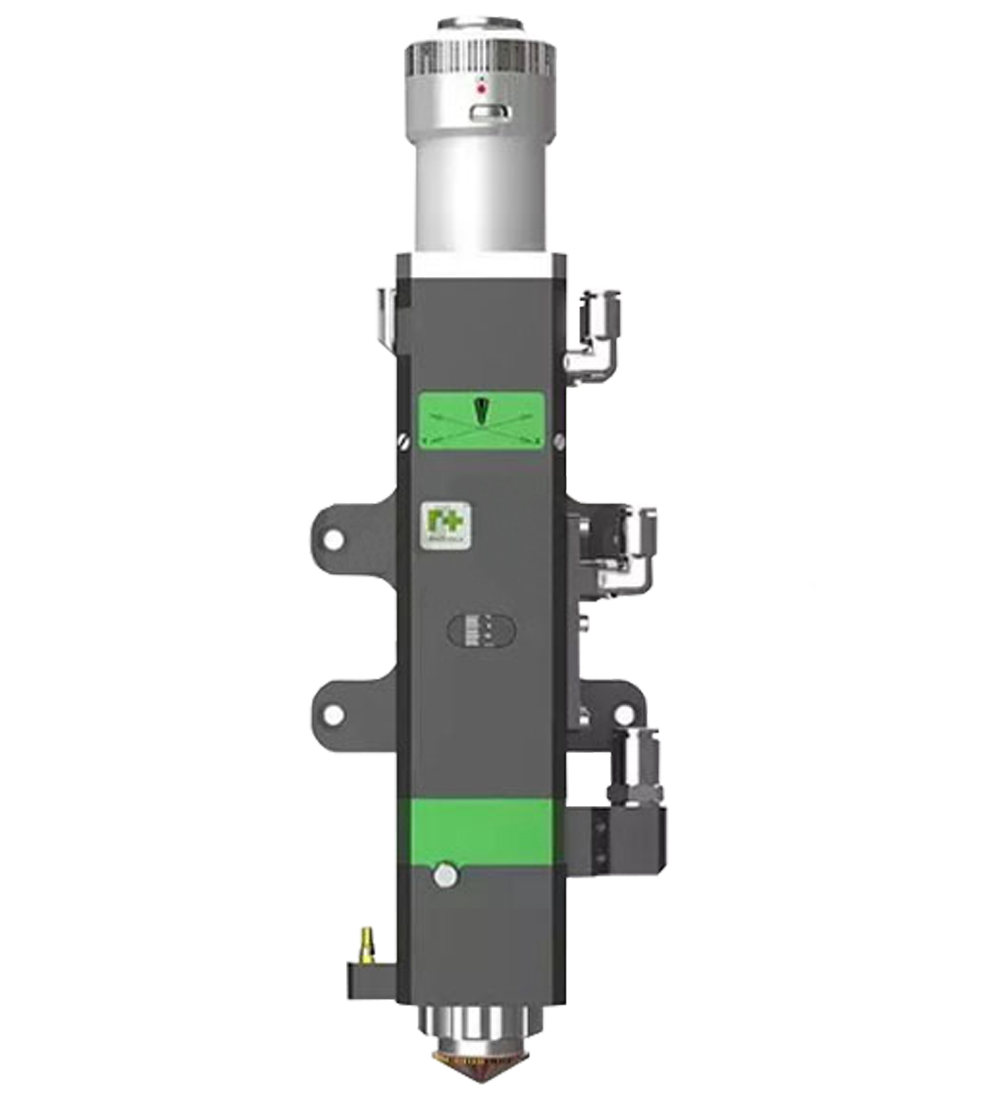

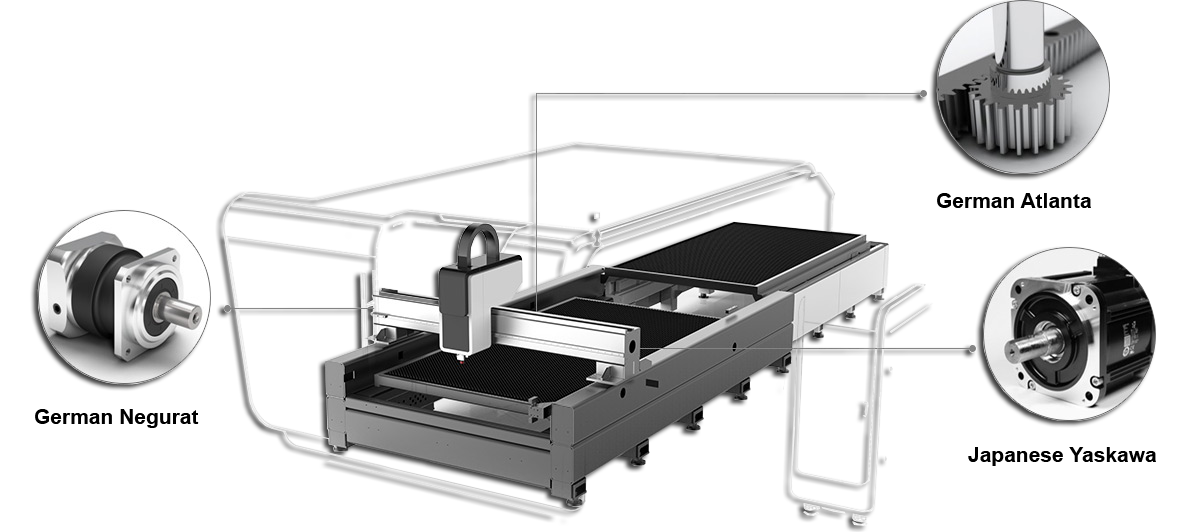

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provides full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The offer includes a laser with a power from 1000W to 8000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

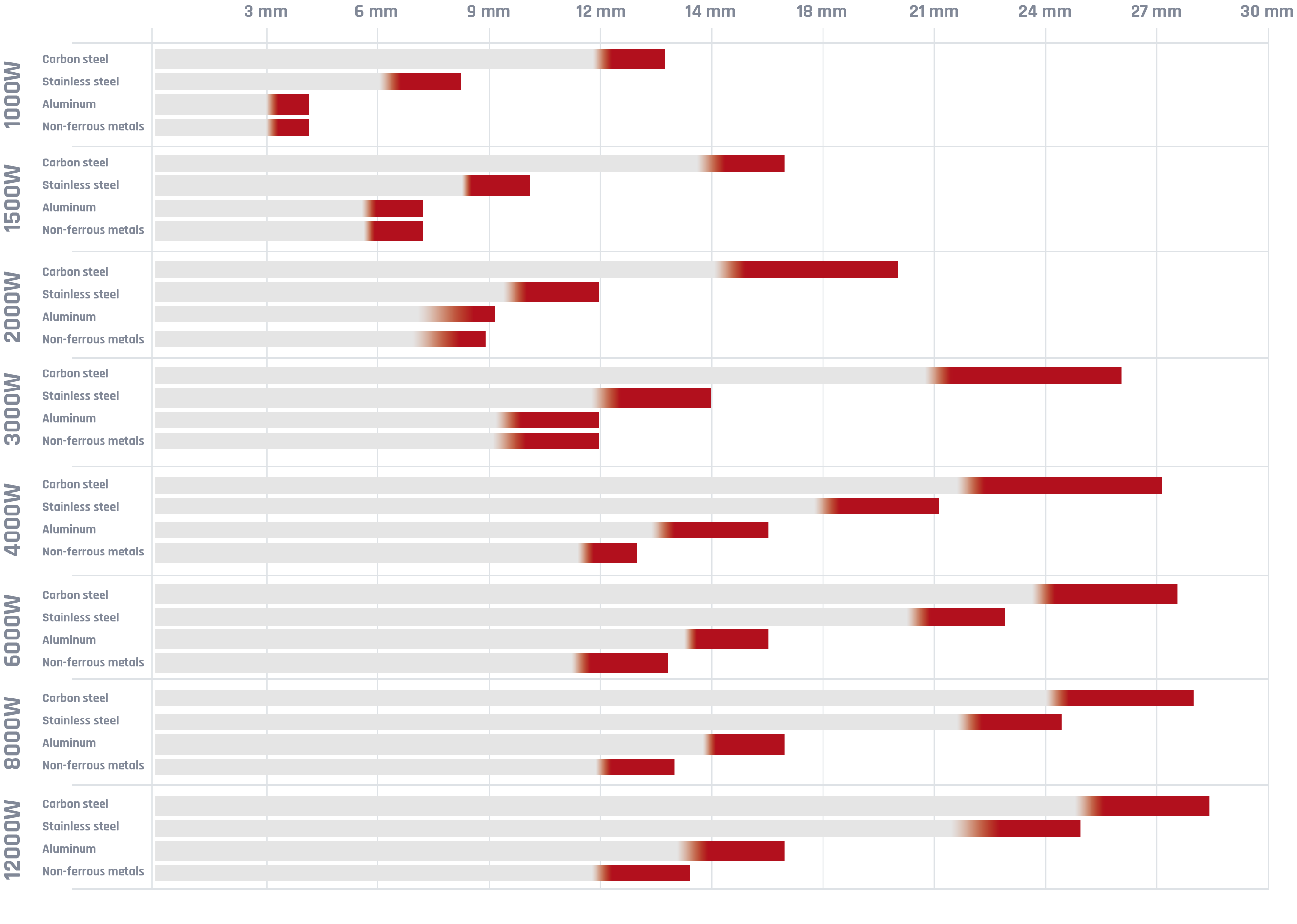

Fiber optics laser cutters constitute modern devices with many advantages. These are not only a perfect and more profitable alternative to the CO2 technology, but they also possess a lot of pros by themselves, such as improving the production by considerable margin and increasing its quality. FIBER technology allows for cutting sheets and other materials of various thickness: from very thin to very thick. The length of a wave in a FIBER laser is 1.064 micrometre long. These properties influence the intensity, which is a hundred times higher than in the case of CO2 devices of similar power.

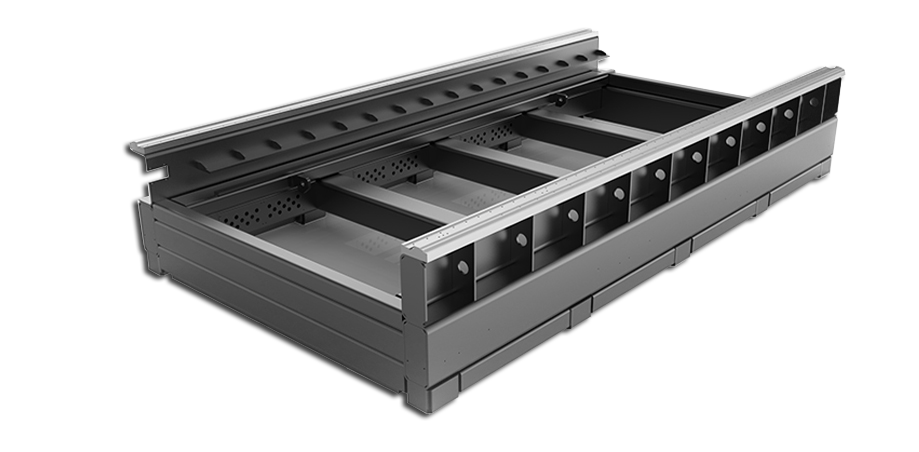

The construction of the sliding gate is made of annealed aircraft aluminium, formed with a strength of 4300 tonnes, achieving unprecedented rigidity. Aircraft aluminium has many advantages: high rigidity (higher than cast iron), small mass, resistance to corrosion and oxidation as well as susceptibility to machining.

The inner structure of the bed forms a metal cell structure similar to a honeycomb patch, which is welded multiple rectangular tubes. Inside these tubes are stiffeners, which improve the durability and the stretching durability and stability of the guide rail, in order to avoid the deformation of the bed.

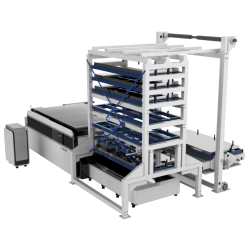

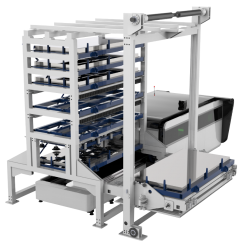

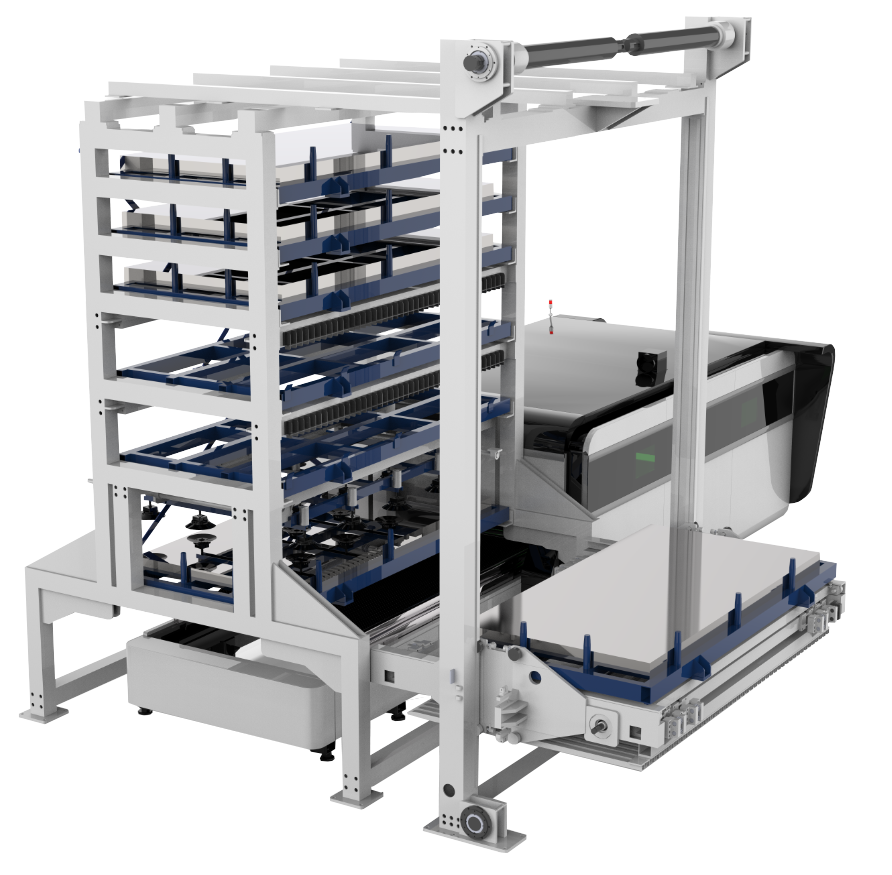

Due to the 6-storey storage system, the material is automatically stored and sorted. This solution significantly reduces labor costs. The warehouse consists of 3 levels: cache level (1 platform), raw material level (3 platforms), finished products level (2 platforms).

The high-resolution camera allows you to control the cutting process without interrupting the process and opening the machine. This impact significantly on the safety and efficiency of work.

| Working area | 1500x3000 |

| Power | 1000W 2000W 3000W |

| Positioning repeatability accuracy | ±0.02 mm/m |

| Maximum speed | 120 m/min |

| Maximum acceleration | 1,5G |

| Maximum platform capacity | 3T |

| Dimensions | 100 mm |

| Power supply | 400V 50Hz |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 1500W handle 240mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which ...More

Fiber laser FIBER LF4020GEP 6000W

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest ...More

Fiber laser FIBER LF4020EP4 3000W

Open FIBER laser with a 2000x4000 mm work table equipped with components from global manufacturers. Our offer also includes other sizes of work tables. Laser cutting machine DESIGNED and ASSEMBLED in POLAND. We configure lasers according to individual customer needs. ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 6000W handle 240mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

FIBER LF1310GEP4 high precision 1500W fiber laser

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing ...More

FIBER LF6015EP4/EU/EP - 1000W Optical Fiber Laser

Fiber laser DESIGNED AND MADE IN POLAND. We configure lasers according to individual customer needs. Fiber laser for cutting large sheets of metal with dimensions of 6000x1500 mm. Thanks to its stable, solid structure and components from global manufacturers, it is ideal for industries where ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 4000W handle 170mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Laser fiber cutting machine LF3015GEP

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Whole cover Fast Fiber Laser cutting machine on Linear Motors

The fastest Fiber Laser on the market that enables the cutting of metal sheets with great precision. The use of linear motors in all axes of the laser cutter guarantees many years of failure-free operation. These drives do not wear out and do not need lubrication. Check out the wide range of fiber ...More

Write your review

* Required fields

I accept privacy policy rules