- On sale!

The basket is empty.

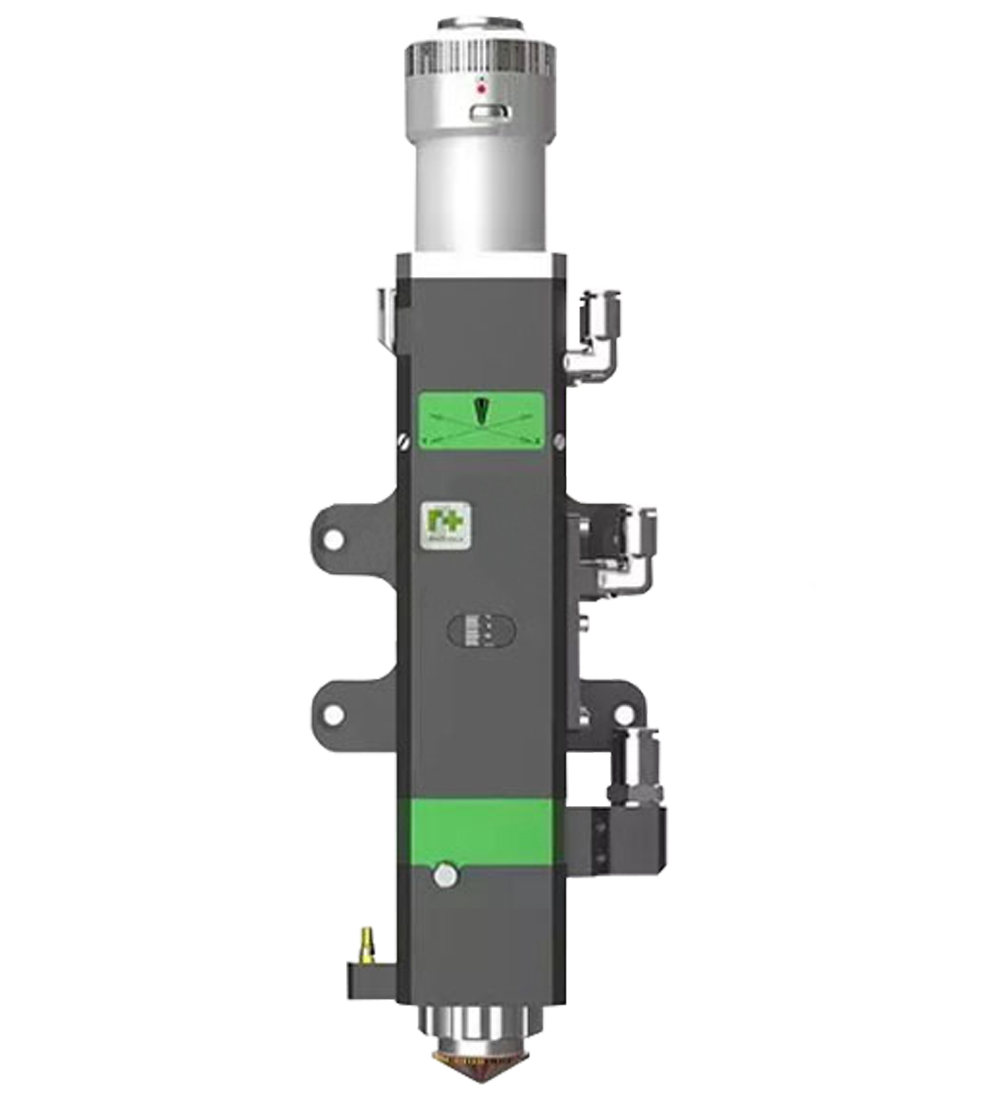

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

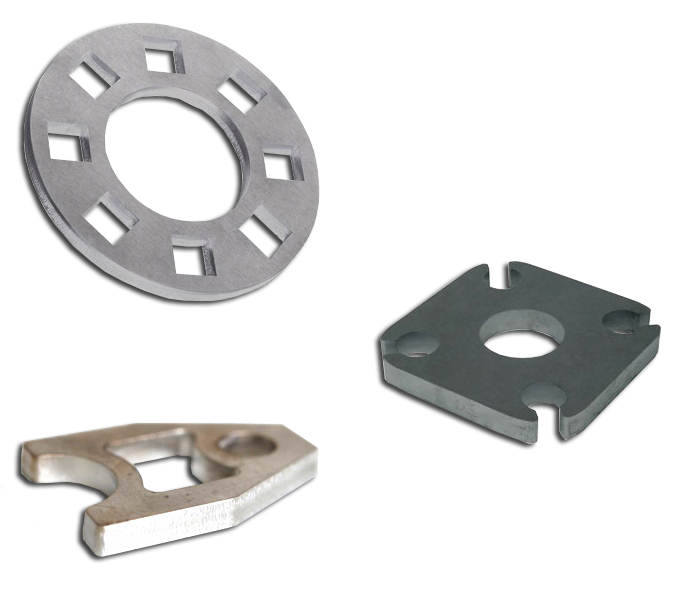

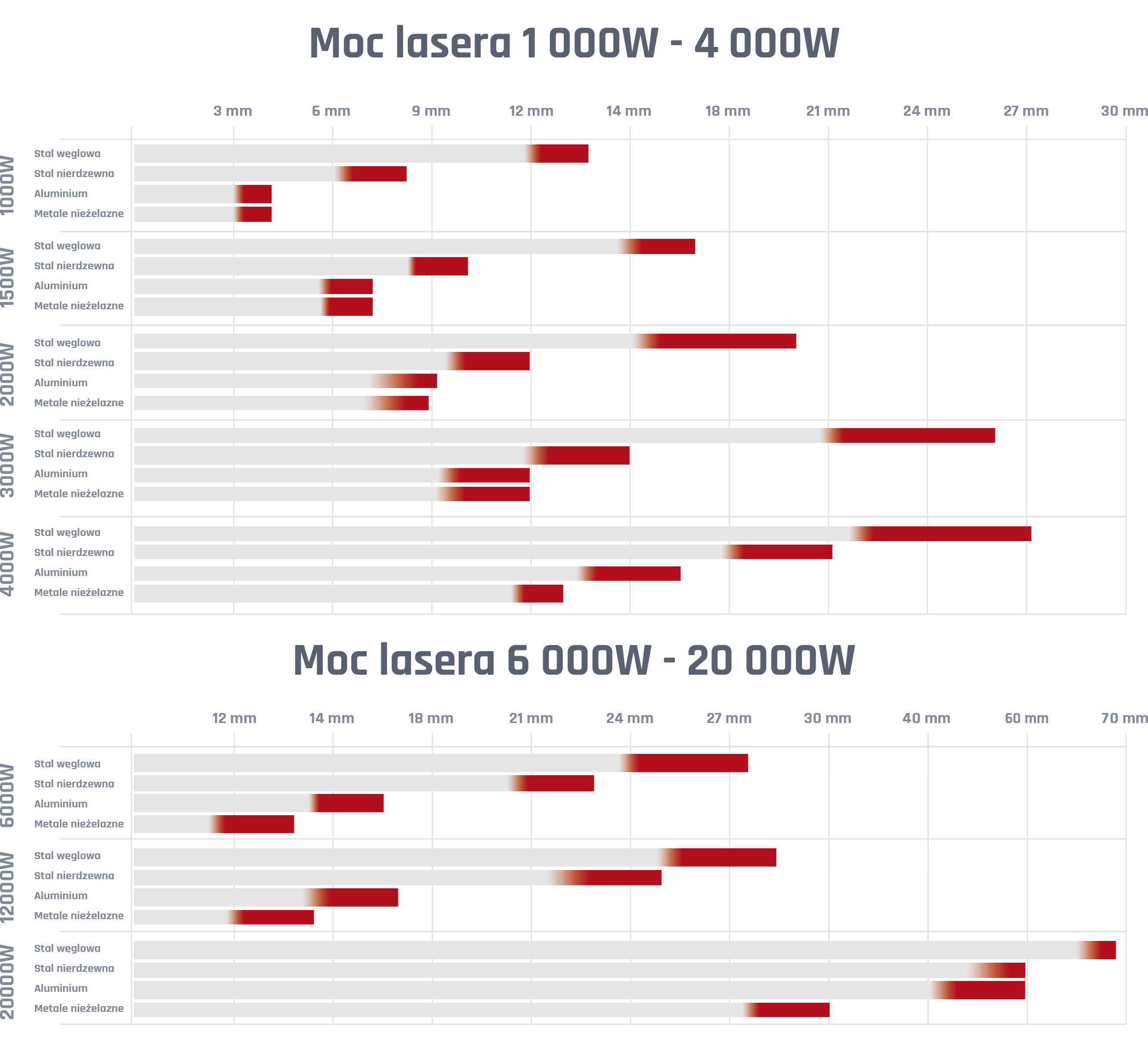

Fiber laser cutters are modern devices that stand out with numerous advantages. They are not only an excellent and much more cost-effective alternative to CO 2 technology , but also have many advantages in themselves, which allow for the development of production (up to 70%) and improvement of its quality. FIBER technology allows for cutting sheet metal and other materials of various thicknesses from very thin to very thick. The wavelength in the FIBER laser is 1.064 micrometers. These properties affect the intensity, which is 100 times greater than in the case of CO 2 devices of similar power.

The sliding gate structure is made of seasoned aircraft aluminum formed with a force of 4300 tons, achieving incredible stiffness. Aircraft aluminum has many advantages: high stiffness (greater than cast iron), low weight, resistance to corrosion and oxidation, and good machinability.

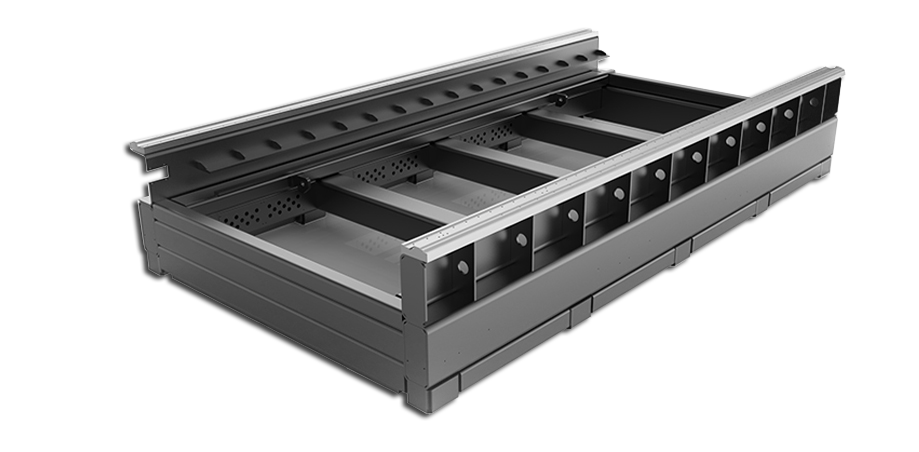

The interchangeable worktable consists of an upper and lower platform, the movement and exchange of which are controlled by the controller. The machine is able to complete the exchange of the platform within 15 s.

The bed structure has an internal structure resembling a honeycomb, made of many rectangular tubes welded together. There are stiffeners inside the tubes, which increase the strength of the bed, and also increase the rigidity and stability of the guide rail to effectively prevent it from deforming. High strength, stability, tensile strength, ensuring 20 years of use without deformation.

| WORKSPACE | 6000x2000 |

| POWER | 2000W |

| REPEATED POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 120 m/min |

| MAXIMUM ACCELERATION | 1.5G |

| DIMENSIONS | 14800x3350x2310 mm |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

CORMAK WL2000 3in1 Laser Welding Machine - Promotional Offer

Introducing the latest model of the CORMAK WL2000 industrial laser welder, which combines advanced FIBER technology with innovative design solutions, offering unparalleled precision and efficiency. This device is designed for welding various types of metals, which ensures the quality and ...More

FIBER LF1310GEP4 high precision 1500W fiber laser

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing ...More

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

FIBER LF1310GEP4 high precision 2000W fiber laser

Laser cutting machine with unprecedented cutting accuracy. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies ...More

FIBER LF3015GA 4000W fiber laser IPG Germany

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Fiber laser FIBER LF4020GEP 2000W

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest ...More

Whole cover laser fiber cutting machine LF3015GA/LF4020GA

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Whole cover Fast Fiber Laser cutting machine on Linear Motors

The fastest Fiber Laser on the market that enables the cutting of metal sheets with great precision. The use of linear motors in all axes of the laser cutter guarantees many years of failure-free operation. These drives do not wear out and do not need lubrication. Check out the wide range of fiber ...More

FIBER LF3015GA fiber laser - 20000W

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Plate and Tube Fiber Laser cutting machine LF3015GEPR

Fiber laser equipped with a turntable for pipes and profiles with a diameter of up to 200 mm and a length of 6000 mm, and a system of interchangeable tables. One machine, two uses. It is an ideal solution for companies with limited space in the hall. YASKAWA servo motors ensure fast and trouble-free operation of the laser. ...More

Fiber laser FIBER LF3015GEP 3000W

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest ...More

Fiber laser FIBER LF6020GEP 6000W

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest ...More

High precision whole cover fiber laser cutting machine LF1310GEP4

A laser cutter with unparalleled cutting precision. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the laser cutter. The use of these components ensures excellent quality even at high laser cutting speeds. The laser housing complies with all safety ...More

Laser fiber cutting machine LF4020GEP

A modern, fully enclosed fiber laser for cutting metal sheets. The laser housing with protective glass provide full protection against the reflection of the laser beam, protecting the health of the operator and other people in the room. The replaceable work table allows you to significantly improve ...More

Fiber laser FIBER LF3015GEP 4000W

Fully enclosed, modern Fiber Laser for cutting sheet metal. The housing with protective glass provides full protection against laser beam reflection, protecting the health of the operator and other people in the room. The offer includes a laser with power from 1000W to 12000W, and the highest ...More

Write your review

* Required fields

I accept privacy policy rules