Machine description:

Electro-welded blade frame with wide thicknesses, rigid and solid structure and 5° inclined base, which allows for better material penetration and high cutting efficiency and stability even when cutting profiles and hard materials.

All machine movements take place on ball screws (frame movement, vice, feeder and blade guide) with high load-bearing capacity and dynamic ability, which reduces friction during travel.

The machine is equipped, thanks to CNC control, with a 3-axis control system managed by a 10" touch screen with an intuitive and user-friendly interface.

The machine controller allows for full control of all operating parameters and setting up to 99 different cutting programs and up to 30 cutting lines, each with different quantities, lengths and angles.

The machines have an encoder on the frame axis, which allows the material to approach to the blade and preview of the descent speed - two parameters that give the user the ability to optimize the cutting process.

The standard vertical cylinder under the blade ensures perfect material locking.

Two hydraulic regulators (on the control panel) control the descent of the frame, acting on the feed speed and blade pressure.

The material is fed by means of a feeder with an electric motor, gear motor, toothed belt and a roller with guide (available length 3000 mm or 6000 mm) - for better stability.

The feeder also allows for a tilting arm system, which also allows for feeding irregular shapes.

The frame rotation is managed by a gear motor with an inverter and toothed belt.

The blade setting is optimized by hardened blade guides and side rollers that always keep the blade close to material.

Low energy hydraulic unit: works only during cutting, and when not needed - switches off automatically.

Possibility to connect the machine to the plant network to improve the flow of information and transform the machine into a professional tool compliant with Industry 4.0. SAWprogram is dedicated software for creating and modifying cutting programs on a PC and sending them directly to the cutting machine. SAWfactory is a WEB application that allows the user to access the machine from any device (computer, tablet, phone), allowing management of work parameters.

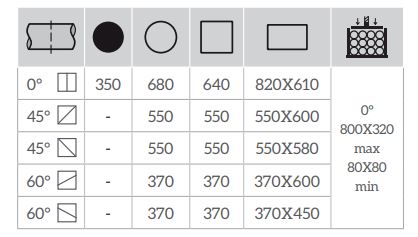

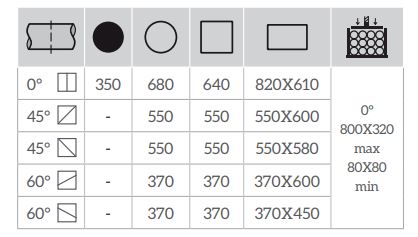

Cutting ranges:

Technical parameters:

|

|

POWER

|

3 phase 400V

|

|

TOTAL POWER

|

7.5 kW

|

|

ARM DROP ADJUSTMENT

|

Hydraulic with smooth adjustment

|

|

CUTTING SPEED

|

18-90 m/min

|

|

VISE BASE HEIGHT

|

855 mm

|

|

TAPE DIMENSIONS

|

8140 x 54 x 1.6 mm

|

|

FINAL WASTE

|

400 mm

|

|

TRAY LENGTH

|

3000 mm

|

|

DIMENSIONS

|

5750 x 4200 x 2750 mm

|

|

WEIGHT

|

5300 kg

|

Write your review

* Required fields

I accept privacy policy rules