- Reduced price

The basket is empty.

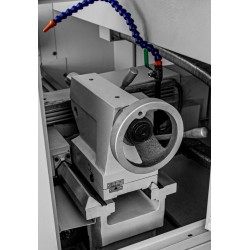

Discover the reliability and versatility of the CORMAK 320x750 CNC Lathe – perfect for precise metalworking and other materials. With its solid cast iron construction, resistant to vibrations, and hardened and ground guides, the machine ensures excellent accuracy and long service life.

Equip your company with the CORMAK 320x750 CNC Lathe and experience efficient and precise machining!

Efficient CORMAK 320x750 CNC Lathe with Optional Equipment for Customization to Your Needs.

With optional equipment, you can customize the lathe to meet your needs. Choose from various controls, such as SINUMERIK 828, add a tool probe for automatic measurement, or a hydraulic chuck for quick and convenient operation. A wide range of additional options, such as a movable support, vapor separator from the cabin interior, or even CAD/CAM software, makes this lathe a versatile tool ready to meet even the most demanding tasks.

|

TURNING DIAMETER OVER BED |

320 mm |

|

TURNING DIAMETER OVER CARRIAGE |

90 mm (option 135 mm) |

|

CENTER DISTANCE |

750 mm |

|

SPINDLE SPEED |

100-2500 rev/min |

|

SPINDLE BORE |

60 mm |

|

SPINDLE TAPER |

MK5 |

|

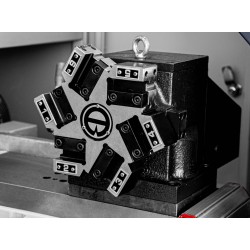

NUMBER OF TOOLS |

4 (option 6,8) |

|

TOOL SIZE |

16x16 mm |

|

MAXIMUM DIAMETER OF ROD IN BORE |

44 mm |

|

TAILSTOCK TAPER |

MT3 |

|

MAXIMUM TAILSTOCK TRAVEL |

100 mm |

|

MOTOR POWER |

5.1 kW (S1), 3.7 kW |

|

DIMENSIONS |

2370 x 1420 x 2000 mm |

|

NET/GROSS WEIGHT |

1040/1300 kg |

We offer professional CNC controls from renowned brands Siemens and Fanuc that ensure precision, efficiency, and ease of use. Our solutions are perfect for both smaller workshops and demanding industrial applications.

Siemens Sinumerik 808D is a modern, economical CNC control designed for basic lathes and milling machines. The system has been designed with small and medium enterprises in mind, offering:

Sinumerik 828D is a professional CNC control designed to work with milling machines and lathes requiring higher precision and efficiency. Its key features include:

This is an excellent choice for companies looking for efficient and reliable CNC control for more complex machining operations.

Fanuc Oi-TF is one of the most popular CNC controls for lathes, known for its reliability and ease of use. This system is widely used in the metalworking industry due to:

With Fanuc Oi-TF, users gain assurance of stable and precise operation, translating into greater efficiency and machining quality.

Choosing the right CNC control is crucial for the efficiency and precision of machining. Siemens Sinumerik 808D is the ideal solution for basic applications, Siemens Sinumerik 828D is suitable for more demanding production processes, while Fanuc Oi-TF guarantees the highest stability and reliability in turning operations.

Feel free to contact us – we will help you choose the CNC control best suited to your needs!

Below are links to the operating instructions for the controllers and documentation for SIEMENS SINUMERIK systems. The files contain detailed information on the operation, configuration, and programming of the devices.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Our CKT660x2000 CNC Lathe is a reliable tool for professionals and novices in series and unit production. This series of heavy-duty lathes is designed for efficient cutting with high accuracy. Thanks to its wide guideways and rigid design, the machine guarantees stability, turning precision and high repeatability of machining. ...More

400x1000 CNC CKT Lathe with Hydraulics

An efficient lathe with a flat bed and a broad scope of big and small scale machining possibilities. This machine can lathe external, internal, spherical surfaces and threads. Using constant cycles for transverse turning, normal turning, tapering, threading, plunge cutting and contouring ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

CKT series flat bed numerical lathes are characterized by high efficiency in series machining. Depending on the version, it can be equipped with a manual or hydraulic lathe chuck with a diameter of 160 mm or a 200 mm option. The CNC machine allows turning external, internal and spherical surfaces ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

The lathe remembers the actions performed by the operator and automatically converts them to G-codes. Then the operator presses the playback button to obtain an identical copy of the processed element. It allows to reduce the setup time of the CNC lathe by half and the work efficiency by 62%. ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

Our CKT 500x1500 CNC Lathe is the epitome of machining excellence. Designed for a wide range of applications, this powerful machine offers not only external, internal, spherical and thread turning functions, but also uses canned cycles that greatly facilitate and speed up the programming and ...More

Our unique CKT660x3000 CNC lathe is a perfect solution for experienced professionals and those who are just starting their adventure in serial and unit production. The series of heavy lathes was designed for efficient cutting, and wide guides and solid construction guarantee stability, precision and repeatability of machining. ...More