- Reduced price

The basket is empty.

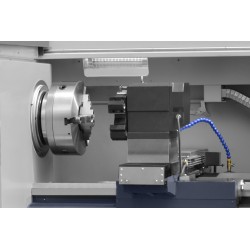

Our CKT 500x1500 CNC Lathe is the epitome of machining excellence. Designed for a wide range of applications, this powerful machine offers not only external, internal, spherical and thread turning functions, but also uses canned cycles that greatly facilitate and speed up the programming and machining process.

Unmatched Features:

When you invest in our CNC Lathe CKT 500x1500, you are investing in excellence. You are not only getting a reliable tool for machining

|

Swing over bed |

500 mm |

|

Swing over cross slide |

280 mm |

|

Maximum turning length |

1500 mm |

|

Main drive |

3 gears |

|

Spindle speed |

50-1300 rpm |

|

Spindle bore |

85 mm |

|

Motor power |

7.5 kW / 11 kW |

|

X/Z axes rapid feed speed |

X:3000 Z:6000 (mm/min) |

|

Positioning accuracy |

X:0.030 Z:0.040 mm |

|

Detail precision |

IT6-IT7 |

|

Roughness |

Ra1.6 |

|

Number of tools in holder |

6-tool head |

|

Tool holder size |

25×25 mm |

|

Dimensions |

2655×1520×1860 mm |

|

Weight |

2400 kg |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

CORMAK CNC LATHE 320x750 HYDRAULIC CHUCK

Discover the performance and versatility of the CORMAK 320x750 CNC Lathe, ideal for machining metal parts and other materials. With a solid cast iron bed, resistant to vibrations, and induction hardened and ground guides, this machine guarantees precision and durability. Equip your ...More

CKT series flat bed numerical lathes are characterized by high efficiency in series machining. Depending on the version, it can be equipped with a manual or hydraulic lathe chuck with a diameter of 160 mm or a 200 mm option. The CNC machine allows turning external, internal and spherical surfaces ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

The lathe remembers the actions performed by the operator and automatically converts them to G-codes. Then the operator presses the playback button to obtain an identical copy of the processed element. It allows to reduce the setup time of the CNC lathe by half and the work efficiency by 62%. ...More

copy of 320x1000 CORMAK CNC lathe

These lathes are ideal for efficient and precise machining of not only metal but also other materials. Features involve machining internal and external cylindrical, frontal, tapered and semicircular surfaces as well as threading. The bed is a solid cast iron, resistant to vibrations. ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More

This lathe saves the actions of its operator and automatically converts them into G-code. Afterwards, the operator can press the playback button in order to achieve an identical copy of the workpiece. This cuts in half the amount of time required to configure the CNC lathe, and increases efficiency ...More