- Reduced price

Extraction and filtering systems are necessary to ensure the safe work of operators and protect laser system components from damage. Filtration, including the use of a carbon filter, is a key step in the process, removing harmful substances and producing clean air. The key benefits of an advanced extraction system such as the LDC-4L include automatic cleaning, 99.9% filtration efficiency, efficient fan and compact design, which together ensure protection, efficiency and extended life of laser systems.

Extraction designed to extract smoke generated during the operation of the fiber laser L.

Laser machining is a process that uses a laser to process materials and is relatively safe and clean. However, this process produces dangerous fumes and dust. They are particularly dangerous to health because they contain heavy metals that can accumulate in the human body. In addition to health risks, laser smoke and dust also have a negative impact on the quality of work, both for the operator and for the machines that may be damaged by contamination. Smoke and laser dust cause contaminants to stick strongly to machine surfaces. Additionally, if important parts of the laser system, such as mirrors or lenses, are covered with contaminants, this can lead to irreversible damage.

Extraction and filtering systems are key elements in any laser installation. They must not only be reliable, but also adapted to specific conditions. Their main task is to ensure the safe removal of smoke and dust, and, if necessary, also to filter these substances. Extraction systems are designed to ensure safe working conditions for operators and keep laser lenses clean, which allows them to maintain their efficiency and durability, as well as minimize unpleasant odors during laser processing.

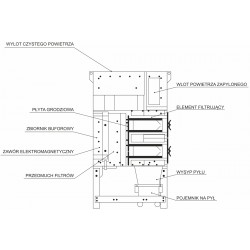

The laser gas and dust filtration process takes place in several stages. First, a filter for coarse particles is used, followed by a filter for fine particles, which consists of polyester material in a metal frame and effectively removes up to 90% of dust and particles from the sucked air. The final stage is the use of an active carbon filter, which, thanks to its special carbon composition, cleans the air of undesirable substances such as heavy metals and toxic chemicals. The carbon surface in this filter acts like a sponge, effectively removing harmful contaminants from the air, which is then released into the room as clean air.

The main functions of the exhaust gas extraction and filtration system in the laser processing process are:

The most important advantages of the LDC-4L extractor:

The extractor has automatic filter cleaning using compressed air. The pressure causes the filter to "shake off", which effectively cleans the filter cartridge and thus extends its life. Thanks to this, the system maintains its performance for a longer time.

The filter element used in the system is imported and made of high-quality material. The fire-resistant Nano filter is characterized by high filtration efficiency, retaining particles up to 0.3 μm in size by over 99.9%.

Large dust collection drawer allows for convenient dust collection and cleaning, making system maintenance easier.

The motors used in the system are equipped with overload protection, thus ensuring a high level of protection and failure-free operation.

The specially developed high-efficiency fan wheel generates large negative pressure, which enables effective laser exhaust removal and ensures high airflow efficiency.

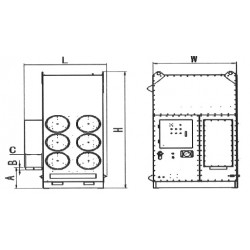

The total purification efficiency of the system is 0.3 μm, and the efficiency is over 99.9%, which proves the high efficiency of the extraction system in removing harmful particles from the air. Additionally, it is characterized by a compact structure, which facilitates operation and maintenance.

| Number of filter cartridges | 4 |

| Airflow | 4000 m³/h |

| Air pressure | 3000 Pa |

| Filtration efficiency | 99.99% |

| Filter size | 350x660 mm |

| Fan power | 5.5 kW |

| Inlet diameter | 250 mm |

| Inlet height | 416 mm |

| Weight | 580 kg |

| Dimensions (L x W x H) | 1350 x 1400 x 2200 mm |

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Industrial smoke and dust extraction LDC-2L

gross €4,699.23

Extraction and filtering systems are essential in the laser processing process. Their task is to safely remove smoke and dust, as well as protect the laser system components from damage. Filtration, including the use of a carbon filter, is a key stage of this process. The filter removes harmful substances, resulting in clean air. The advantages of an advanced extraction system such as the LDC-2L include automatic cleaning, filtration efficiency of 99.9%, efficient fan and compact design. Together, this ensures protection, efficiency and extended life of laser systems1.

Fume and dust extraction filter LDC-2L

gross €243.59

The filter element used in the system is imported and made of high quality material. The Nano-type fire-resistant filter has a high filtration efficiency, holding particles of 0.3 μm in excess of 99.9%. The price is for 1 piece

Industrial smoke and dust extraction TODC-4L

gross €11,322.30

The LDC-6L extraction system is an advanced solution ensuring protection and efficiency in the laser processing process. Thanks to automatic filter cleaning, 99.9% filtration efficiency, efficient fan, and compact design, this system ensures operator safety, maintains the efficiency of laser systems and minimizes contamination. This is not only the effective removal of harmful substances from the air, but also care for the continuity of operation and durability of the equipment. Extraction designed to extract smoke generated during the operation of the fiber laser L.

Industrial smoke and dust extraction TODC-6L

gross €14,192.29

Extraction designed to extract smoke generated during the operation of a fiber laser

Industrial smoke and dust extraction TODC-8L

Extraction designed to extract smoke generated during the operation of a fiber laser

Industrial smoke and dust extraction TODC-4L

gross €11,984.60

Extraction designed to extract smoke generated during the operation of the fiber laser L.