Machining of Non-Ferrous Metals and Aluminium

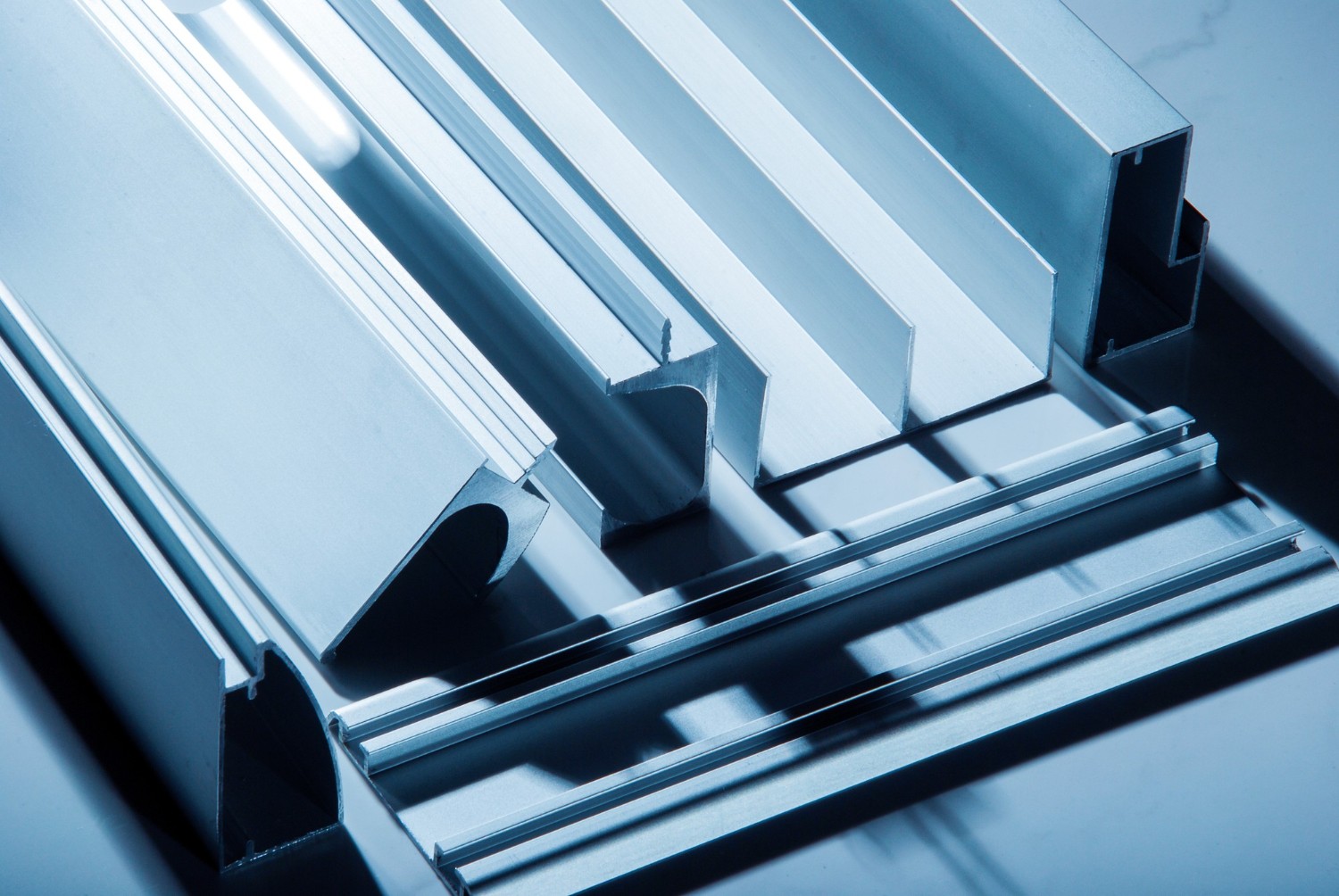

The machining of copper, aluminium, or other non-ferrous metals is one of the most commonly used technological processes in the metal industry. It involves removing excess material from the workpiece in the form of chips. This process is used to obtain precise shapes and surfaces of high quality. In the case of non-ferrous metals such as brass, aluminium, or copper, machining requires specific tools and technological parameters to ensure proper quality and efficiency.

Many industries, including automotive, aerospace, electronics, and construction, rely on the machining of non-ferrous metals valued for their properties such as lightness, corrosion resistance, and ease of processing. In this article, we discuss how to machine brass, aluminium, and copper, and how to choose the right machines for these processes.

- Machining brass

- Machining aluminium alloys

- Machining copper

- Machining non-ferrous metals – general rules

- Summary

Machining brass

Brass is an alloy of copper and zinc, characterized by good mechanical properties and excellent machinability. In brass machining, cutting tools that allow precise material removal without deformation are used. Brass responds well to milling, turning, and drilling, making it suitable for mechanical parts such as valves, pipes, fittings, and machine components.

For effective brass machining, it is crucial to select proper cutting parameters, such as cutting speed, depth of cut, and choice of cutting tools. It is advisable to use appropriate metalworking machines for this purpose.

Machining aluminium alloys

Aluminium and its alloys are widely used in various industries, particularly in aerospace, automotive, and construction. Machining aluminium alloys requires specific tools, as aluminium has low hardness and is easy to cut. The tools must be wear-resistant and have proper geometry to ensure a clean and accurate finish.

Machining aluminium alloys is typically performed using milling machines, metal lathes, and CNC machines, which allow precise removal of material in one or multiple passes. Proper cooling is especially important to prevent overheating and tool damage.

Machining copper

Copper, like other non-ferrous metals, has high electrical and thermal conductivity, making it ideal for electronic components, wiring, and electrical systems. However, copper is prone to deformation and tends to form long chips, which can complicate the machining process.

To machine copper effectively, it is necessary to use suitable cutting tools and adjust machine settings to reduce the risk of overheating. Choosing optimal parameters such as cutting speed, cutting depth, and coolant pressure is crucial for achieving high-quality results.

Machining non-ferrous metals – general rules

The machining of non-ferrous metals requires consideration of the specific properties of each material. Brass, copper, and aluminium alloys differ in their physical and mechanical characteristics, which affect the choice of tools and cutting parameters. Proper ventilation and cooling during machining are also essential to prevent overheating of materials and tools.

All machining operations must follow appropriate standards and specifications to ensure product quality. Machines should be adapted to the material being processed. Investing in CNC machines guarantees precision and repeatability in various materials.

Summary

The machining of aluminium, brass, and copper is a key process in producing precision mechanical components. It requires suitable cutting tools, accurate machines, and optimized parameters to ensure top-quality results. Thanks to modern technology and CNC systems, machining non-ferrous metals has become easier and more efficient, enabling complex production across many industries.

To optimize machining processes, it is worth investing in metalworking machines that provide precision, reliability, and efficiency. These are offered by Cormak, a leading manufacturer of industrial machines.

See also our related article: What is metal cutting and how does it work?