How do you satinise aluminium?

Wondering what aluminium satin finishing is? The elegant, silky-matte surface of aluminium catches the eye and impresses with its durability in a world where design meets functionality. Aluminium satin finishing is a modern surface treatment method that gives the metal a unique semi-gloss or matte finish. This process not only enhances the aluminium's appearance but also increases its resistance and durability, making it increasingly popular in furniture, decorative elements, and bathroom fittings. This blend of beauty and practicality makes satin-finished aluminium a true trend in contemporary design.

In this article:

- Aluminium satin finishing: what it is and how the process works

- Aluminium satin finishing: advantages and applications

- Aluminium satin finishing: professional services and technologies

Aluminium satin finishing: what it is and how the process works

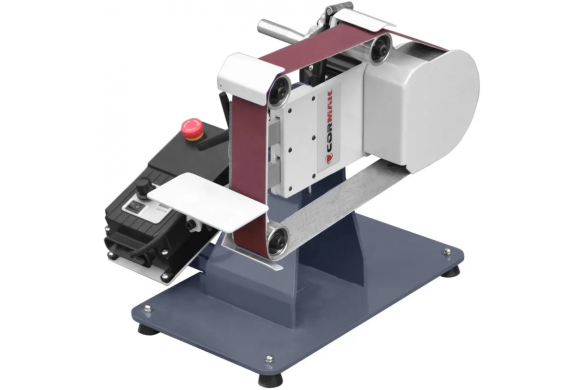

Aluminium satin finishing is a surface treatment process that gives the material an elegant matte or semi-gloss appearance. Unlike polishing, satin finishing creates a uniform, silky texture that effectively masks minor imperfections. It is used for both aesthetic and practical reasons – improving scratch and wear resistance. The process involves abrasive belts and rotary brushes operating under controlled mechanical conditions. Properly selected tools, such as abrasive strips and brushes mounted on metalworking machines, ensure precision and consistency. Their parameters – speed and pressure – are key to the result. Coarser abrasives are used at the beginning, and finer ones in the finishing stage to achieve a subtle surface texture.

The process starts with cleaning and degreasing the aluminium. An abrasive paste is then applied to help remove micro-damage. The initial stage involves grinding the material with more aggressive tools to level the surface. Finer grains and lower speeds are then used to create a satin effect and avoid streaks. This requires operator experience, especially for complex shapes. Tools used include fibre discs (grit 40–120), abrasive cloths, and nonwoven abrasives. These tools work with devices such as disc grinders and metal polishers, allowing for precise parameter adjustment depending on the aluminium type. In the final stages, polishing pastes are used to smooth the surface and give it a consistent appearance.

Aluminium satin finishing: advantages and applications

One of the main advantages is aesthetics – the matte, silky surface with uniform lines fits perfectly with modern design. Satin finishing effectively hides scratches and imperfections, giving materials a luxurious feel. Beyond visual appeal, satin finishing improves aluminium’s resistance to scratches and external factors. The treated texture withstands daily use better and is easier to clean – dirt and fingerprints are less visible. Thanks to these properties, satin-finished aluminium is widely used. In decoration, it is used for accessories, panels, frames, and lighting elements. In furniture, it appears as a finish for handles, legs, and fronts. It also performs well in kitchens and bathrooms, as well as in the automotive industry – as a detail in cockpits, trim, or housings. In construction, it is used in balustrades, ventilation, and partition walls.

Aluminium satin finishing: professional services and technologies

Modern aluminium satin finishing plants rely on automated systems that ensure consistent results and high efficiency. Professional services use machines such as industrial satin finishing machines and robotic grinding stations, enabling precise treatment of even complex parts. Thanks to modern technologies, not only is satin finishing possible, but also real-time monitoring of parameters, which allows immediate correction of any deviations. To achieve the desired effect, selecting the right process parameters is essential:

-

Abrasive grain size – coarse grains for initial treatment, finer ones for finishing.

-

Tool diameter – typically 100–125 mm, for a balance of efficiency and precision.

-

Pressure force – too much may damage the surface, too little – yields no result.

We provide the technology and machinery as a manufacturer of industrial machines, constantly developing our offer to meet the needs of industry and craftsmanship. Our range includes modern industrial machines that enable efficient processing of various aluminium alloys and achieve uniform finishing in a short time.