The basket is empty.

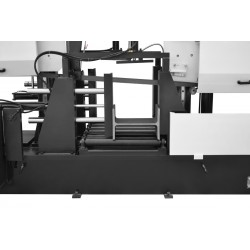

The CORMAK H-65/80 double-column band saw is a highly efficient machine for semi-automatic cutting of solid materials and profiles made of steel, cast iron and non-ferrous metals. The two-column construction ensures greater rigidity during the cutting process, and the use of a completely different arm and belt guiding technology compared to scissor machines significantly reduces the time and increases the cutting precision.

In the semi-automatic band saw CORMAK H-65/80, after switching on the switch, the entire cutting cycle, i.e. fixing the cut material in a hydraulic vice, switching on the cutting band, lowering the cutting arm (speed continuously adjustable), stopping the machine after the cut, raising the arm (height arm lift is adjustable) and the hydraulic vice is switched off automatically. Manual operation of the machine has been simplified to feed the cut material to the stop. A massive arm made of a uniform cast iron together with a refined, massive and stable construction provides the CORMAK H-65/80 cutter with exceptional rigidity, which translates into trouble-free operation and very high cutting precision.

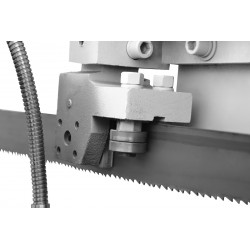

Belt tension allows for optimal belt working conditions. If the saw blade breaks, the machine stops automatically. The precision of the belt guidance is ensured by guides consisting of bearings and inserts made of sintered carbides. Innovation and production of CORMAK semi-automatic and automatic series cutters according to norms and standards compliant with ISO:90001 and ISO:140001 certificates, guarantee safety, quality and reliability of the product. The use of motors licensed by a well-known and respected manufacturer on the global market, one of the world's leaders, ABB, guarantees long and trouble-free operation.

| CUTTING BAND SPEED | 40/45/65/76 m/min | |||

| MAXIMUM CUTTING RANGE | Ø650 mm| 800 x 650 mm | |||

| TABLE HEIGHT | 600 mm | |||

| CUTTING BAND SIZE | 7400 x 54 x 1,6 mm | |||

| CUTTING BAND CLEANING | Wire brush and coolant | |||

| VICE CLAMP AND CUTTING BAND TENSION | hydraulic | |||

| MOTOR POWER | 7.5 kW | 400V | |||

| HYDRAULIC MOTOR POWER | 1.5 kW | |||

| COOLER MOTOR POWER | 0.125 kW | |||

| MACHINE WEIGHT | 3200 kg | |||

| DIMENSIONS | 3450 x 1550 x 2380 mm | |||

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

S-200RH Semi-Automatic Band Saw

Powerful, reliable and modern semi-automatic band saw for metal with automatic arm raising and lowering and a hydraulic vice. The arm is rotational in both ways from -45º to +60º. The machine is fantastic for ironworking, e.g. cutting tubes and profiles. ...More

CORMAK Semi-automatic BS-370H Metal Band Saw 400V 27mm

The semi-automatic band saw CORMAK BS-370H, thanks to the hydraulically controlled vice and saw arm, cooling, swivel arm enabling cutting at an angle from -45° to +60°, in combination with saw blades from the renowned German company Rontgen, is widely used in all locksmith workshops where precision, quality and cutting speed count. ...More

CORMAK H-50/70 is a highly efficient column band saw for semi-automatic cutting of steel profiles, cast iron and non-ferrous metals. Its column design ensures rigidity during cutting, and employment of a completely different arm guiding technology than in pivot band saws provides cutting time ...More

CORMAK BS-530H semi-automatic band saw

Semi-automatic band cutter Cormak BS-530H - it is a proven product that enjoys great recognition. It offers a wide range of features such as: Cutting range from -45° to +60°. Stepless cutting speed adjustment and hydraulic vice ensuring maximum comfort of work. A solid construction that ...More

Semi-automatic double column metal band saw CORMAK H-700

The CORMAK H-700 twin-column band saw is a high-performance machine for semi-automatic cutting of solid materials and profiles made of steel, cast iron and non-ferrous metals. The two-column construction ensures greater rigidity during the cutting process and the use of a completely different ...More

Write your review

* Required fields

I accept privacy policy rules