The basket is empty.

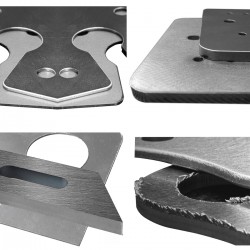

The SG1000H grinding and deburring machine perfectly prepares stamped and laser-cut parts for further processing. It removes any burrs and edges are rounded more evenly than when machining by other methods.

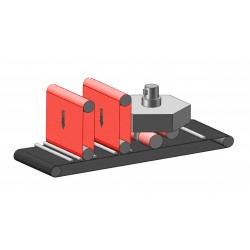

It is a single-sided machine in which the workpieces are moved on a conveyor belt under two grinding belts and three flap brushes working from above. The rotating brushes machine the edges of the workpieces.

CORMAK SG1000H – the universal deburring and edge rounding machine

The SG1000H is a versatile and innovative solution that delivers excellent results in the processing of punched and laser-cut parts. It is ideal for both deburring and edge rounding, as well as optional surface finishing according to customer requirements.

The SG1000H is as flexible as the laser itself. In one work cycle:

Thanks to the vacuum table, the SG1000H allows the processing of both large elements with extensive surfaces and small details made of steel and non-ferrous metals.

The SG1000H can cope with any challenge:

The machine is equipped with three key working units:

The heart of the machine is the innovative rotor, which works evenly on all sides on the edges of the sheet metal, guaranteeing extremely precise rounding.

The advanced control module automatically adjusts the settings to the details parameters, ensuring process optimization and the desired results. The system monitors brush wear, taking it into account in the machine settings.

SG1000H is the most universal deburring and edge rounding machine in the CORMAK family - irreplaceable in plants that expect the highest quality of detail processing. Choose perfection and flexibility!

| Max. working width | 1000 mm |

| Working thickness | 0 - 80 mm |

| Minimum workpiece size | 50 x 50 mm |

| Table feed speed | 1-5 m/min. |

| Tape head: | |

| Roller diameter | 130 mm |

| Sanding belt dimensions | 1030 x 1900 mm |

| Main motor | 7.5 kW |

| Planetary head: | |

| Sanding roller dimensions | fi 300 x 295 mm, bore 32 mm |

| Roller drive motors | 2 x 2.2 kW, 30-1300 rpm |

| Planetary rotation motor | 5.5 kW 1-17 rpm |

| Suction nozzle diameter | 200 mm |

| Operating temperature range / humidity | +5 - +40°C, 5-85% |

| Noise level | ok. 80 dB |

| Power | 400 V |

| Weight | 1500 kg |

| Machine dimensions | 2570 x 1620 x 1980 mm |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Automatic Grinder Deburring Machine for Metal CORMAK - SG1000

The SG1000 grinding and deburring machine perfectly prepares stamped and laser-cut parts for further processing. It removes all burrs, and the edges are rounded more evenly than when processing with other methods. This is a single-sided device in which the parts are moved on a conveyor belt ...More

Deburring machine, polishing machine, sheet metal grinder CORMAK SZLIFMASTER-E

CORMAK SZLIFMASTER-E is an efficient machine for deburring, grinding and polishing sheet metal. Equipped with a mobile head, magnetic table with remote control and a vacuum system, it ensures precise and convenient processing of details. Thanks to the rotating head and ergonomic arm, it is an ...More

Professional double-disc brush grinder BMS2080 with a base

The brush grinding machine with a base, equipped with 250 mm diameter wire brushes included in the set, makes this model ideal for both professional applications and hobbyists. The stable and rigid construction ensures quiet operation with no vibrations. ...More

CORMAK BMS250 industrial double-disc grinder with a base

Two-disc grinder equipped with two discs with a diameter of 250 mm for a wide range of applications. A grinding disc with a diameter of 250 mm, a powerful 900 W drive motor and a round wire brush included in the set make this model perfect for both professional applications and DIY enthusiasts. ...More

Write your review

* Required fields

I accept privacy policy rules