Technical parameters

| Turning diameter over bed |

600 mm |

| Turning diameter over support |

390 mm |

| Max workpiece length |

1500 mm |

| Travel in X / Z axis |

1200 mm |

| Through spindle |

52 mm (68, 89 mm option) |

| Spindle speed |

3000 rpm /min. |

| Chuck size |

210 |

| Spindle motor |

11 kW |

| Positioning accuracy X / Z |

0.001 mm |

| Tool size |

20x20 mm |

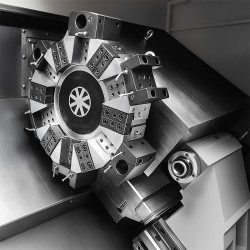

| Number of tools |

12 |

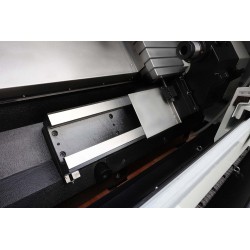

| Tailstock sleeve diameter |

88 mm |

| Tailstock sleeve extension |

85 mm |

| Tailstock Cone |

MK5 |

| Dimensions L/W/H |

3700x1800x2100 mm |

| Weight |

5800 kg |

Available equipment

- SINUMERIK 808D control in Polish

- automatic reception Part (option)

- 12-tool head (OPTION driven tools)

- chip collection

- SIEMENS servo drives

- 3-jaw hydraulic lathe chuck

- soft jaw set

- hydraulic tailstock

- cooling system

- automatic lubrication system for gears and guides

- 24V halogen lighting

- user manual in Polish

CNC controls – Siemens Sinumerik 808D, SINUMERIK 828D and Fanuc Oi-TF

We offer professional CNC controls from renowned brands Siemens and Fanuc, which ensure precision, efficiency and ease of use. Our solutions are ideal for both smaller workshops and demanding industrial applications.

Siemens Sinumerik 808D – compact CNC control for basic applications

Siemens Sinumerik 808D is a modern, economical CNC control dedicated to entry-level lathes and milling machines. The system was designed with small and medium-sized enterprises in mind, offering:

- Intuitive operation – a simple interface based on a graphic screen that makes it easy to program and configure the machine.

- High reliability – a durable design resistant to difficult working conditions in the workshop.

- Wide compatibility – adapted to machines with basic technological requirements.

- A perfect solution for beginner CNC users who want to start working on a modern control system.

Siemens Sinumerik 828D – advanced control for demanding applications

Sinumerik 828D is a professional CNC control designed to work with milling machines and lathes requiring greater precision and efficiency. Its key features include:

- High computing power – fast data processing enables dynamic and accurate machining.

- Extensive technological functions – advanced machining cycles, interpolation and tool path optimization functions.

- Solid, compact design – designed to work in difficult industrial conditions.

- Easy integration with automation – expandable with additional modules and production process control options.

- Compatibility with CAD/CAM – seamless cooperation with design software and production management systems.

This is an excellent choice for companies looking for efficient and reliable CNC control for more complex machining operations.

Fanuc Oi-TF – stability and precision in machining lathe

Fanuc Oi-TF is one of the most popular CNC controls for lathes, known for its reliability and ease of use. This system is widely used in the metalworking industry due to:

- Exceptional stability - reliability and precision of operation even in long-term serial production.