- On sale!

Open fiber laser with source power from 1000W to 4000W. The laser is standardly equipped with a nesting program, which makes working with the laser faster and also minimizes material loss. Fiber laser DESIGNED and ASSEMBLED in POLAND. We configure lasers according to individual customer needs.

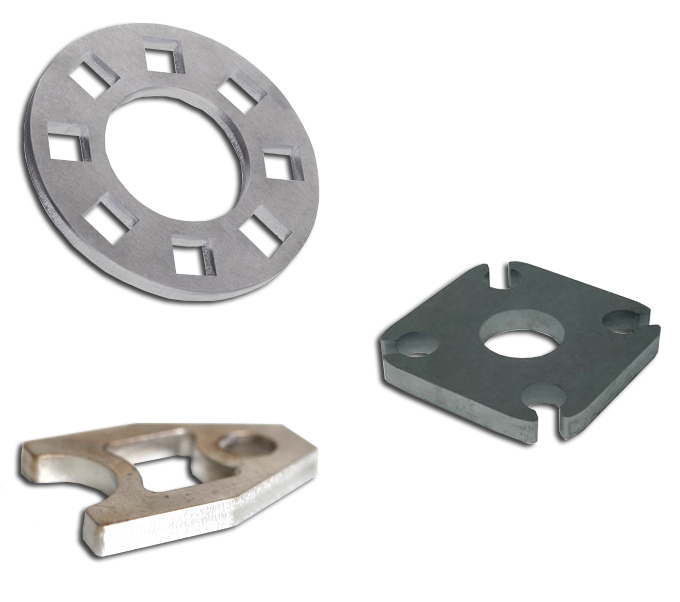

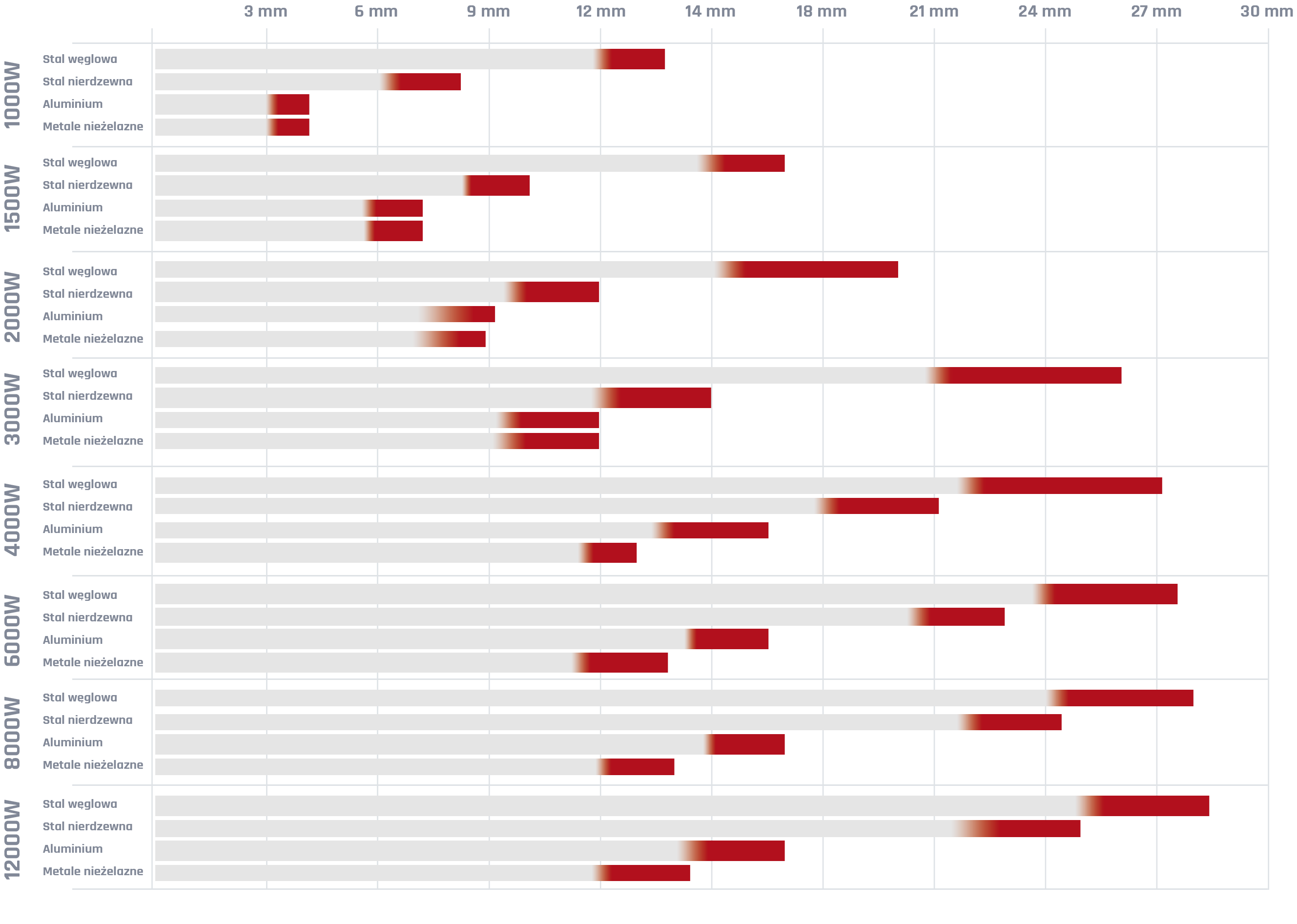

Fiber optic laser cutting machines are modern devices with numerous advantages. Not only are they an excellent and much more profitable alternative to CO2 technology, but they also have many advantages that allow you to expand production (up to 70%) and improve its quality. FIBER technology allows you to cut sheet metal and other materials of various thicknesses, from very thin to very thick. The wavelength of the FIBER laser is 1.064 micrometers. These properties influence the intensity, which is 100 times greater than in the case of CO2 devices with similar power.

THE GREATEST ADVANTAGES OF THE LASER ARE:

Fiber laser

The screen has a vertical display with fast response time, higher contrast, wider view, low power consumption and high resolution. In addition, it is characterized by a high level

of brightness and lower reflectance, as well as greater durability.

The bed structure has an internal structure resembling a honeycomb, made of many welded rectangular tubes. There are stiffeners inside the tubes that increase the strength of the bed and also increase the stiffness and stability of the guide rail to effectively prevent it from deforming. High strength, stability, tensile strength, ensuring 20 years of use without distortion.

| WORK SPACE | 1500x3000mm |

| POWER | 3000W (option: 1000W, 1500W, 3000W, 4000W) |

| REPEATABLE POSITIONING ACCURACY | ±0.02 mm/m |

| MAX SPEED | 40 m/min |

| DIMENSIONS | 3800x2180x2000mm |

| POWER | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

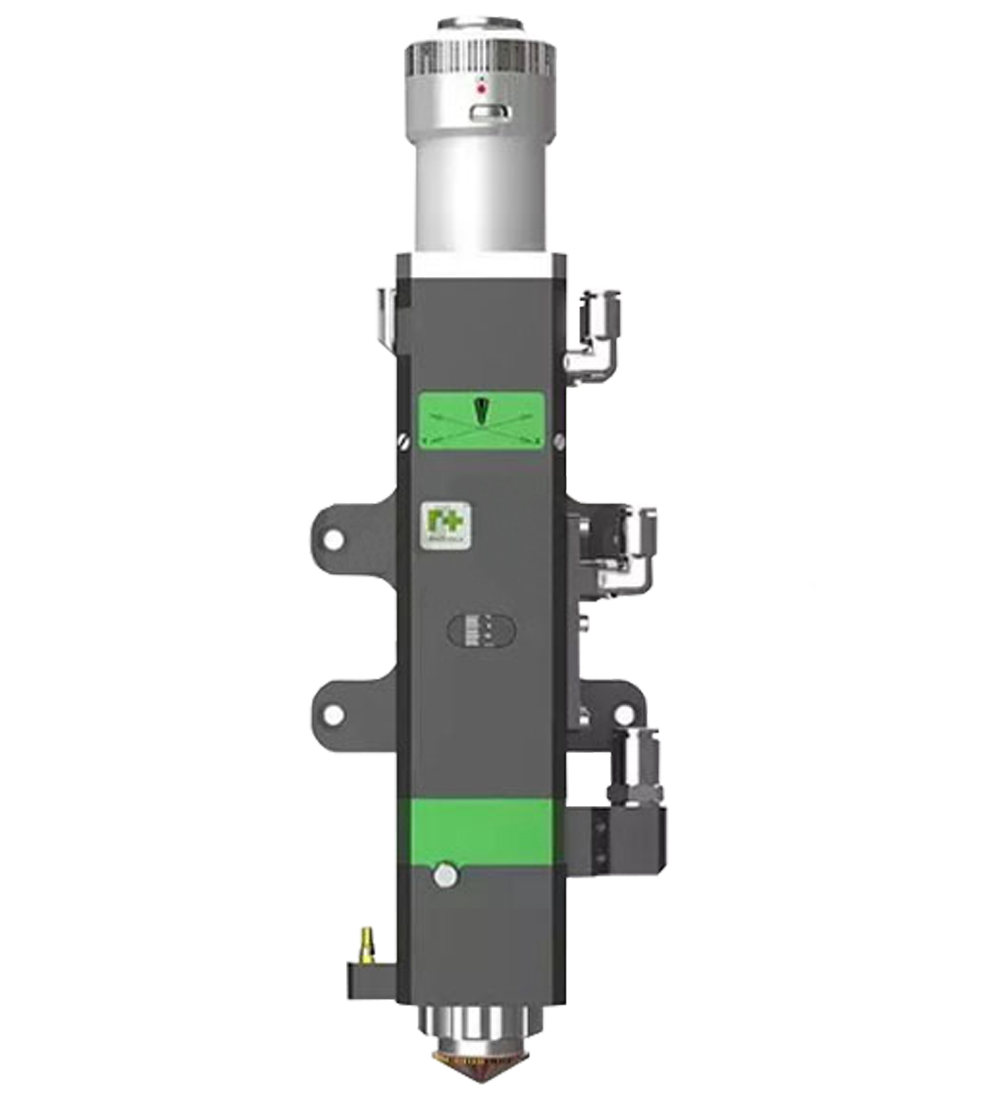

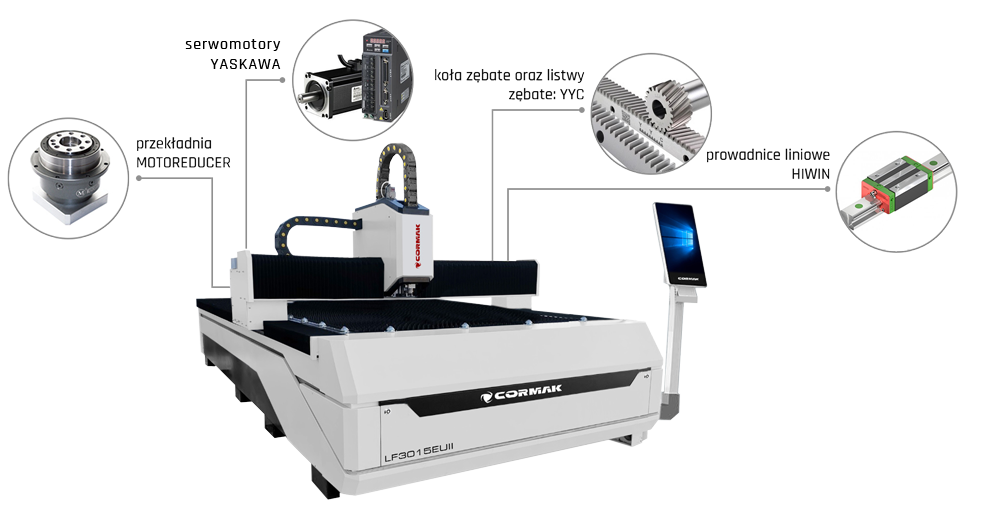

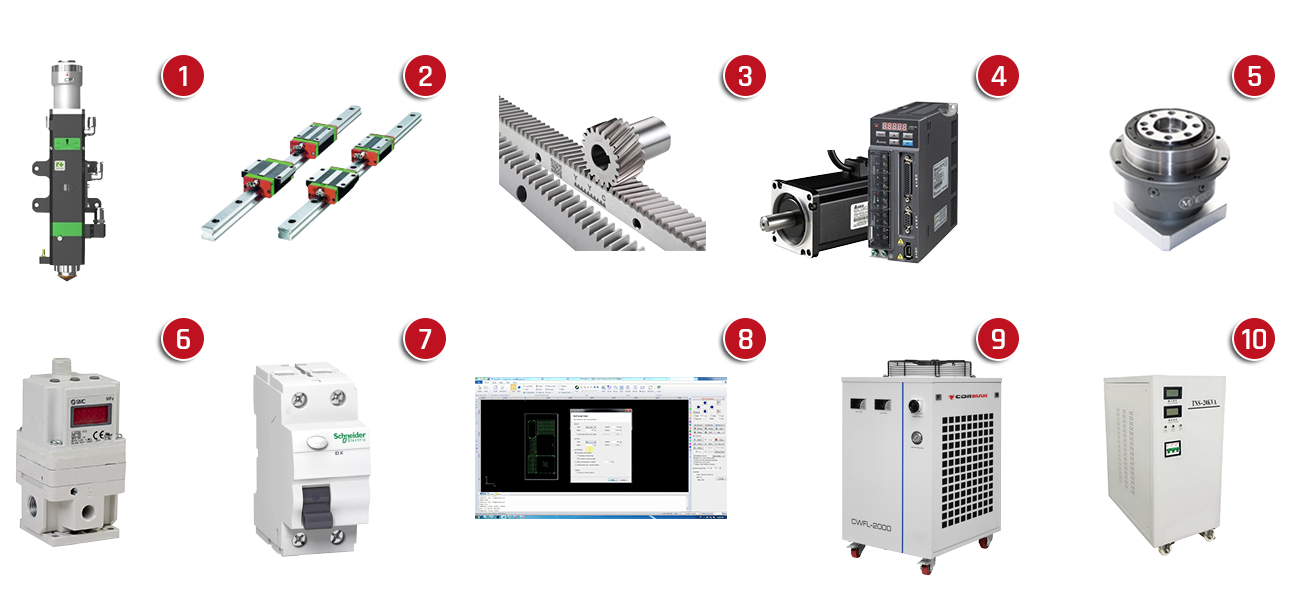

1. RAYTOOLS head

2. linear guides: HIWIN

3. gears and toothed bars: YYC

4. DELTA servomotors

5. MOTOREDUCER gear

6. SMC pneumatic components

7. electronic components such as contactors, relays, sensors from: Schneider, OMRON, IDEM

8. CypCut program

9. Chiller (water cooler): S&A

10. TNS voltage stabilizer

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Open fiber laser with source power from 1000W to 4000W. The laser is standardly equipped with a nesting program, which makes working with the laser faster and also minimizes material loss. Fiber laser DESIGNED and ASSEMBLED in POLAND. We configure lasers according to individual customer needs.