The machine body is a cast iron casting mounted on a rigid, spatial plate housing structure. Inside the housing there are: a hydraulic unit, a coolant tank with a pump and a chip feeder. The steel frame structure is inclined at a 3-degree angle to the surface of the feeding table, which is particularly advantageous when cutting rectangular elements and profiles.

The cutting band drive based on an inverter-controlled motor provides smooth adjustment in a wide range of speeds. In the event of a saw break, the machine stops automatically. Precise band guidance is provided by guides consisting of guide bearings and carbide inserts. The movable tape guiding head is set depending on the size of the cut material, which ensures increased stability of the tape operation. Maximum cutting parameters and extended saw life are ensured by the cooling system and cleaning brush.

The hydraulically forced arm drop is regulated in a wide range by a precise throttle valve. The fast feed system allows for shortening the cutting time of individual elements.

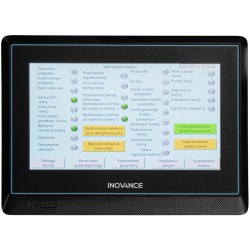

The hydraulic material feeding system ensures a fully automatic machine work cycle. The controller equipped with an LCD display allows programming of the saw operation, signals the end of material, communicates errors and informs about the number of cut sections after the programmed time has elapsed. The maximum length of material feeding in one stroke is 500 mm with an accuracy of +/- 0.2 mm per stroke.

The innovation and production of CORMAK semi-automatic and automatic series cutting machines according to norms and standards compliant with ISO:90001 and ISO:140001 certificates, guarantees safety, quality and product reliability. The use of engines licensed by a well-known and respected manufacturer on the global market, one of the world leaders, ABB, guarantees long and failure-free operation.

2022-05-29

Łatwa wymiana taśmy

Można szybko i sprawnie wymienić taśmę bez użycia dodatkowych narzędzi.