- On sale!

The basket is empty.

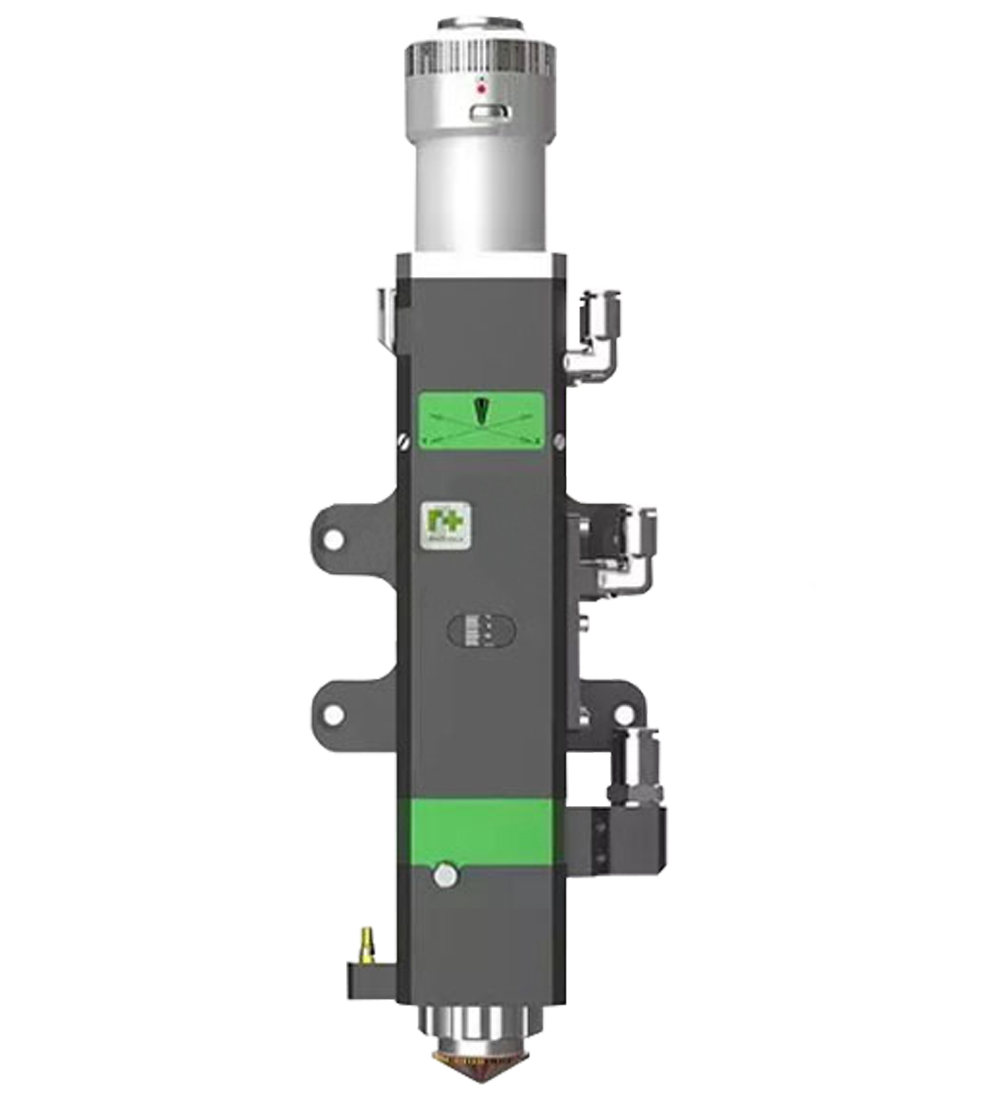

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into high cutting quality. The high-performance fiber laser is characterized by low operating costs and failure-free operation for many years. The intuitive user interface and advanced software make the machine easy to operate, making it an ideal solution for companies striving to increase production efficiency.

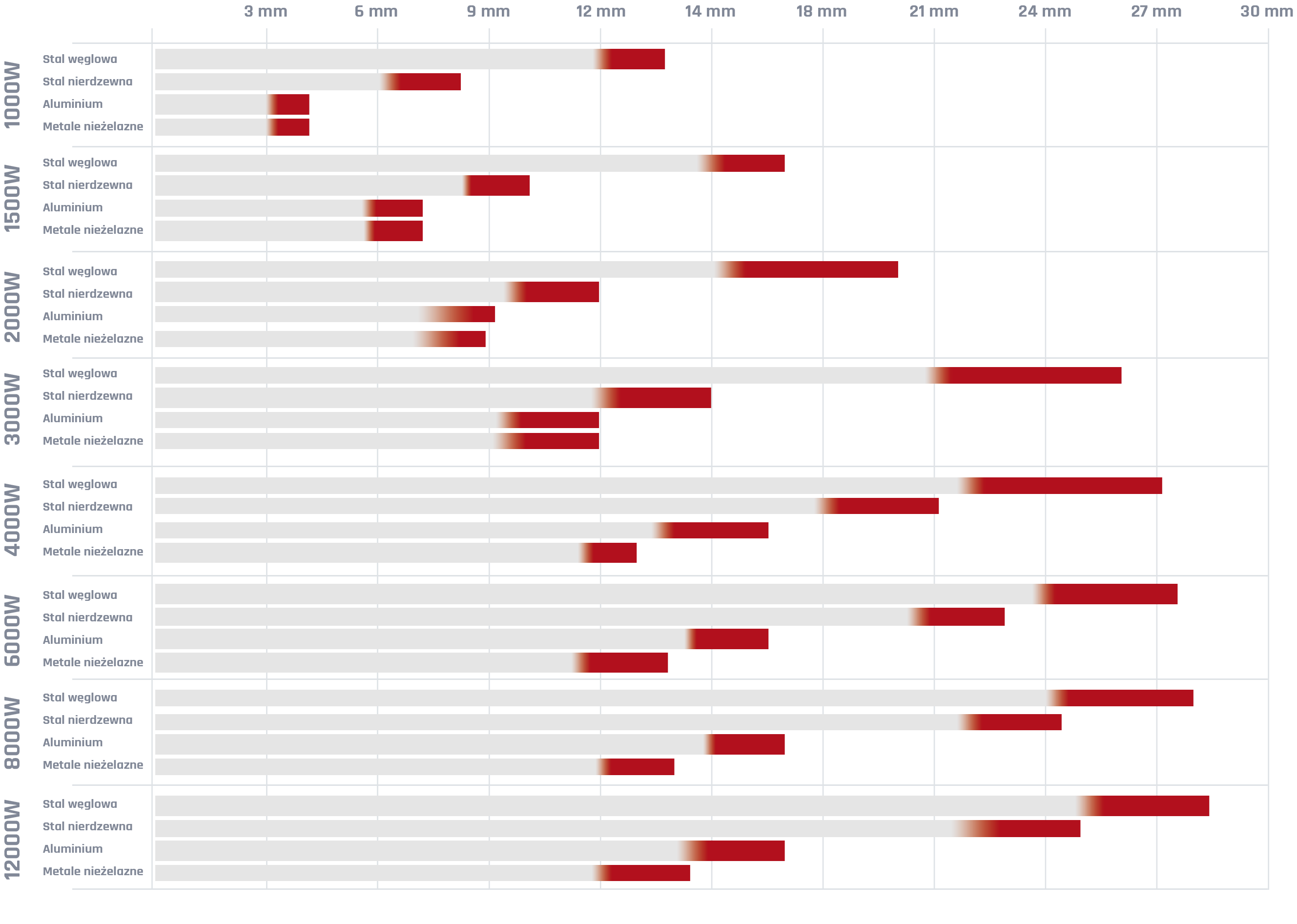

Laser cutters are modern devices that stand out with numerous advantages. They are not only an excellent and much more cost-effective alternative to CO2 technology, but also have many advantages in themselves, which allow for the development of production (up to 70%) and improvement of its quality. FIBER technology allows for cutting sheet metal and other materials of various thicknesses from very thin to very thick. The wavelength in the FIBER laser is 1.064 micrometers. These properties affect the intensity, which is 100 times greater than in the case of CO2 devices of similar power.

THE GREATEST ADVANTAGES OF LASER ARE:

Fiber laser

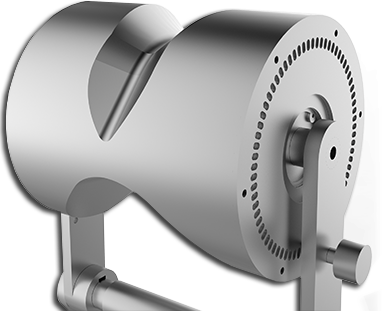

The LF3015EPR fiber optic cutting machine not only cuts sheet metal, but also pipes and profiles. It has many applications and allows you to save space by more than 50%, which effectively increases productivity.

The interchangeable worktable consists of an upper and lower platform, the movement and exchange of which are controlled by the controller. The machine is able to complete the exchange of the platform within 15 s.

The clamp grips the profile in two directions and automatically aligns the profile. The diagonal adjustment range is 20-170 mm.

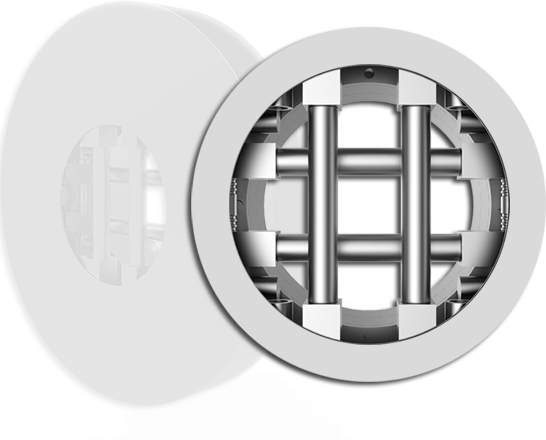

The bed structure has an internal structure resembling a honeycomb, made of many rectangular tubes welded together. There are stiffeners inside the tubes, which increase the strength of the bed, and also increase the rigidity and stability of the guide rail to effectively prevent it from deforming. High strength, stability, tensile strength, ensuring 20 years of use without deformation.

It adopts an intelligent pipe support assembly to solve the deformation problems in the process of cutting long pipes.

| WORKSPACE | 1500x3000 |

| POWER | 4000W |

| REPEATED POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 50 m/min |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

FIBER LF60M Tubes and Profiles Optical Fiber Laser

High-class laser for cutting pipes and profiles with high accuracy (± 0.03 mm). The electric clamping clamp and the intelligent pipe support enable the cutting of pipes and profiles with a diameter of 20-200 mm. The set also includes an easy-to-use wireless controller so that the operator does not ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 2000W handle 170mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 1500W handle 350mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which ...More

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 6000W handle 350mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

FIBER LF60170 fiber laser for pipes and profiles

The latest model of a fiber laser for cutting pipes and profiles, equipped with an automatic storage-feeder for details and a receiving storage for ready elements. The automation of the laser cutting process significantly increases the efficiency of work. We offer the following laser powers: 1000W, ...More

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 4000W handle 170mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 3000W handle 350mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which ...More

FIBER LF60300 fiber laser for pipes and profiles with a semi-automatic feeder

The latest model of fiber laser for cutting pipes and profiles, equipped with an automatic warehouse-feeder for details and a receiving warehouse for finished elements. Automation of the laser cutting process significantly increases work efficiency. We offer the following laser powers: 1000W, 2000W, 3000W, 4000W, 6000W. ...More

Fiber laser with pipe and profile cutting attachment FIBER LF3015EPR 3000W handle 170mm

Technologically advanced laser cutting machine for cutting sheet metal, pipes and profiles DESIGNED AND ASSEMBLED IN POLAND . It uses components from leading manufacturers, which ensures reliability and durability. A solid and rigid bed minimizes vibrations, which translates into ...More

Write your review

* Required fields

I accept privacy policy rules