The basket is empty.

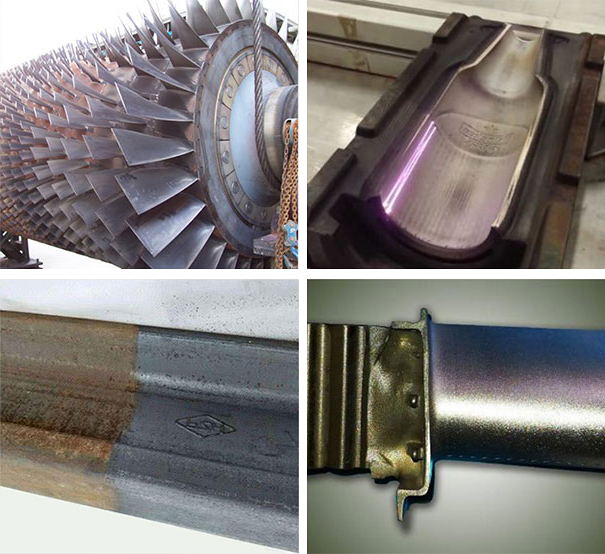

The new generation of laser cleaning devices is a breakthrough in the cleaning industry. Thanks to the latest laser technologies, it is possible to effectively remove paints, oils, dirt, rust, deposits and resins that are difficult to remove using traditional methods. Removing dirt or coatings is a non-contact process, which eliminates the risk of damaging the surface, does not cause material abrasion. This technology is used in various fields, from the automotive industry to aviation, shipbuilding - where traditional methods fail. The laser cleaning process is gaining recognition in companies dealing with renovation and sandblasting. Modern devices are equipped with advanced control systems, allowing precise adjustment of parameters to each task.

The new generation of surface cleaning device provides excellent efficiency and is characterized by ease of installation and operation. This makes it ideal for various applications, from industrial to utility. Removing paints, oils, dirt, rust, deposits or resins becomes easier than ever before, and all this thanks to advanced laser technology. Control in Polish.

One of the key advantages of laser cleaning is its environmental friendliness. The lack of chemicals means that the process does not cause chemical corrosion, which translates into a smaller burden on ecosystems.

Additionally, thanks to precise control systems, the device can effectively clean a variety of surfaces, such as aluminum, stainless steel or structural steel, without the risk of damage. The ability to adjust the strength and shape of the beam also allows you to adjust the parameters to the surface being treated and your needs.

As a result, the fiber laser cleaning machine is becoming an indispensable tool in many industries, delivering excellent cleaning results with minimal risk of material damage. Thanks to its versatility and effectiveness, it is becoming an indispensable element of production and maintenance processes, contributing to both increased efficiency and environmental protection.

| Laser power | 1000 W |

| Total power | 4kW |

| Power supply | 230V |

| Scanning Frequency Range | 10 - 100 Hz |

| Cable length | 7 m |

| Pulse frequency | 5 - 100 kHz |

| Weight | 180kg |

| Dimensions | 700x1200x1250mm |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

The new generation of laser cleaning devices is a breakthrough in the cleaning industry. Thanks to the latest laser technologies, it is possible to effectively remove paints, oils, dirt, rust, deposits and resins that are difficult to remove using traditional methods. Removing dirt or coatings is ...More

The latest generation device for surface cleaning. Ideal for cleaning paints, oils, dirt, rust, tarnish, resin, etc. The laser is used wherever standard cleaning techniques have failed. Laser cleaning does not cause abrasion, is non-contact and does not cause overheating of the material ...More

The latest generation device for surface cleaning. Ideally suitable for cleaning paints, oils, dirt, rust, tarnish, resin, etc. The laser is used wherever standard cleaning techniques have failed. Laser cleaning does not cause abrasion, is non-contact and does not cause overheating of the material ...More

The latest generation device for surface cleaning. It is ideal for cleaning paints, oils, dirt, rust, tarnish, resin, etc. The laser is used wherever standard cleaning techniques have failed. Laser cleaning does not cause abrasion, is non-contact and does not overheat the material ...More

CZL2000 Fiber Optic Cleaning Laser

The new generation of laser cleaning equipment is a breakthrough in the cleaning industry. Thanks to the latest laser technologies, it is possible to effectively remove paints, oils, dirt, rust, tarnish and resins that are difficult to remove using traditional methods. Laser cleaning offers many ...More

Write your review

* Required fields

I accept privacy policy rules