The basket is empty.

The latest model of the CORMAK EBM120 edge bander with a base, equipped with a polisher, milling, automatic application of glue to the table top and veneer.

EDGEBANDER IS EQUIPPED WITH AUTO-FEED OF THE WORKTOP AND EXTRACTION FAN FOR MILLING UNITS

The EBM120 oiler and edge bander with extraction is a powerful device that significantly facilitates and improves the processing of wood-like materials.

Strong and Stable Pressure: The EBM120 oiler and edge bander is characterized by a strong and stable pressure that ensures even operation. This allows you to achieve perfect processing results.

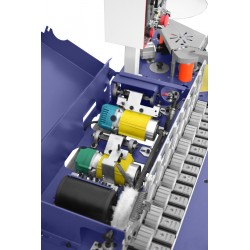

Edge Polishing Option: The machine is equipped with the option of polishing a previously milled edge, which allows you to obtain a perfectly smooth and aesthetic finish of the processed materials.

Extraction for milling units: This device has an extraction system that is useful when working with milling units, which helps keep the workplace clean.

Smoothly Adjustable Automatic Feed: EBM120 is equipped with a smoothly adjustable automatic feed of the processed material, which ensures precision and comfort during work.

Two milling units: The machine is equipped with two milling units that enable processing both the upper and lower parts of the countertop, which increases the efficiency of the machining process.

Comfortable Veneer Feeding Arm: EBM120 has a comfortable veneer feeding arm, which makes the operator's work easier and contributes to the efficiency of the process of wrapping materials.

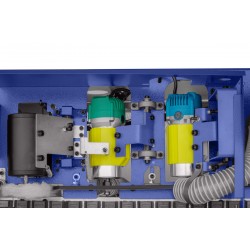

Automatic activation of the veneer pick-up rollers: The veneer pick-up rollers turn on automatically when the appropriate melting temperature of the glue is reached, which increases the precision and safety of the banding process.

Polishing Speed Adjustment: The polishing speed automatically adjusts to the feed speed, which ensures an even and aesthetic finish of the processed elements.

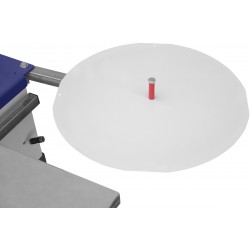

Banding of irregularly shaped countertops: The machine enables gluing of irregularly shaped countertops by moving the glue feeding head to the side position, which increases its versatility.

Worktop with Automatic Feed: The worktop is equipped with automatic feed and support rollers, which facilitates the movement of material during work. Adjustable rollers allow the processing of larger materials.

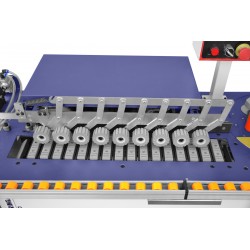

Pressure Rollers and Reinforced Pressure Strip: The pressure rollers are slanted, which helps guide the table top and prevents it from rolling back. Additionally, the reinforced aluminum pressure bar ensures even distribution of the pressure force and stability of the workpiece.

The EBM120 edge bander with extraction is an advanced device that guarantees precision, durability and efficiency when processing wood-like materials. Its advanced technological solutions and convenient functions make it irreplaceable in the carpentry and window industry.

| Total power demand | 3.2 kW |

| Power | 230V |

| Banding height | 7 - 60 mm |

| Milling height | 7 - 45 mm |

| Tape thickness | 0.3-3 mm |

| Heating speed | 5 - 10 minutes |

| Banding speed | 0-6 m/min |

| Glue tank capacity | 1000 ml |

| Cutter shank | 1/4" |

| Dimensions | 2050 x 900 x 1170 mm |

| Weight | 82 kg |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Poziom hałasu jest niski, co jest dużym plusem w warsztacie.

Za tę cenę maszyna oferuje naprawdę świetne rezultaty – polecam.

Okleiniarka zajmuje niewiele miejsca, a jednocześnie oferuje wiele funkcji.

Brzegi są perfekcyjnie wykończone, nawet przy trudniejszych materiałach.

Panel sterowania jest intuicyjny, obsługa nie sprawia żadnych problemów.

Proces oklejania jest szybki i wydajny, co oszczędza mnóstwo czasu.

Maszyna jest bardzo wytrzymała i stabilna w użytkowaniu.

Cormak EBM120 okleja bardzo precyzyjnie, brzegi wyglądają idealnie.

2021-11-03

Energooszczędna

Maszyna zużywa niewiele energii, co jest zauważalne na rachunkach.