The basket is empty.

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers, which provide a wide range of functions, enabling the implementation of the most demanding bending tasks.

| Max. thickness of bent sheet metal (S235) | up to 3.0mm |

| Nominal pressure | 400kN |

| Maximum length of bent sheet metal | 1600mm |

| Depth of cut in beams (throat) | 200mm |

| Maximum stroke of the moving beam | 100mm |

| Maximum opening height | 300mm |

| Distance between beams | 1200mm |

| Rear bumper departure | 600mm |

| Engine power | 4.0kW |

| Length | 1800mm |

| Width | 1200mm |

| Height | 1850mm |

| Weight | 2750 kg |

Ensures the same bending angle along the entire bending length - (option)

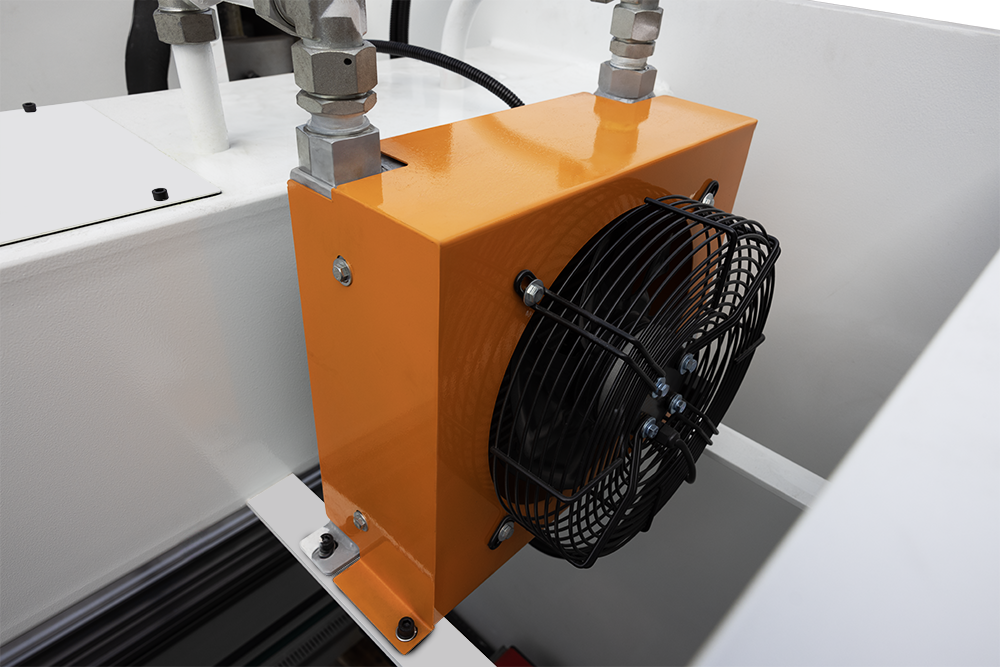

The SOil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous use.

The machine combines advanced technology with ease of use, making it an ideal choice for both precise manual tasks and efficient series work. High-quality components and advanced safety features guarantee reliability and safety of use.

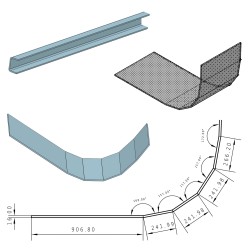

In order for the effect of the step bending to be satisfactory, it is necessary to perform certain calculations, which, however, require knowledge of several of the most important parameters related to the bending process – these are:

Due to the final effect, the appropriate selection of press brake tools, i.e. the die and the punch, is also important.

Although the entire step bending process may seem quite complicated, the machines and software available from CORMAK are already so advanced that in many respects they completely replace the operator.

CORMAK press brakes continuously measure the bending process and can, for example, correct deviations during the process to achieve the most optimal effect.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

street Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Doskonała prasa, idealna do intensywnej produkcji, precyzyjna.

Solidna maszyna, świetna jakość i precyzja. Polecamy każdemu.

Prasa działa bez zarzutu, zapewnia dużą dokładność i niezawodność.

Używamy jej codziennie, jest niezawodna, łatwa w obsłudze.

Hydraulic press brake CORMAK CNC SERVO EURO PB 125x2500

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 40x2500

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers, which provide a wide range of functions, enabling the implementation of the most demanding ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 80x2000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers, which provide a wide range of functions, enabling the implementation of the most demanding ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 125x4000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 160x3200

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 60x1600

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 200x6000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 63x2500

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 500x4000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 200x3200

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 80x2500

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers, which provide a wide range of functions, enabling the implementation of the most demanding ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 200x2500

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 300x6000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 40x2000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers, which provide a wide range of functions, enabling the implementation of the most demanding ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 250x5000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

Hydraulic press brake CORMAK CNC SERVO EURO PB 300x5000

Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with CORMAK CR-41 controllers and which provide a wide range of functions that allow for the implementation of the most ...More

2025-01-18

Wysokiej klasy urządzenie

Prasa krawędziowa CNC to inwestycja, która się opłaca. Sprawdziła się w naszej firmie.