What is a CNC lathe and what does a CNC turner do?

What is a CNC Lathe?

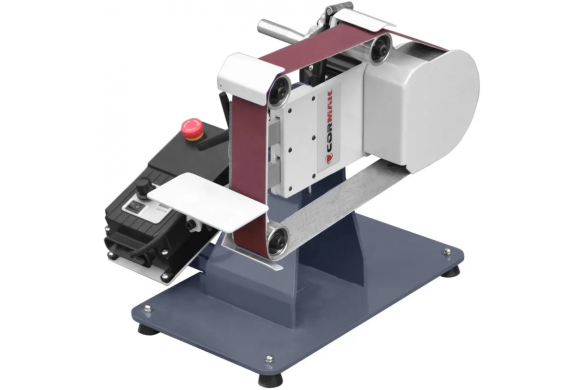

A CNC lathe is a machine that combines traditional machining techniques with modern computer control. This allows for precise shaping of various materials, creating complex components with accurately defined parameters. In the range of CNC machines available on the market, there are different types of lathes tailored to users' needs:

-

Flat-bed CNC lathes – ideal for simple and intermediate tasks.

-

Slant-bed CNC lathes – provide greater rigidity and precision.

-

CNC lathes with driven tools – enable simultaneous turning and milling.

-

Teach-in CNC lathes – ideal for manual and automatic operation.

-

Specialized CNC lathes – designed for specific applications.

CNC lathes are widely used in the automotive, aerospace, medical industries, and machine component manufacturing. Their precision and automation make them essential equipment in modern machining centers.

Who is a CNC Lathe Operator and What Are Their Tasks?

Wondering who a CNC lathe operator is and what they do? They are responsible for operating, programming, and overseeing the lathe's work. Their tasks include not only starting the machine but also preparing the material, setting up tools, and supervising the entire machining process. This position requires both technical knowledge and programming skills.

What Does a CNC Lathe Operator Do?

The main responsibilities of a CNC lathe operator include:

- Preparing materials and the machine

The operator selects the appropriate material for machining and installs the tools in the metalworking machine, considering the task requirements. - Programming the lathe

Using specialized software such as G-Code, the operator creates control instructions that define the machine's operations. - Supervising the machining process

The operator monitors machine performance, checks technical parameters, and responds to any deviations. - Quality control

After machining, the operator verifies that the parts meet design specifications using precision measuring tools. - Machine maintenance and diagnostics

Regular maintenance and quick identification of malfunctions are key aspects of the operator’s job.

Advantages of CNC Lathes in Industry

CNC lathes are characterized by high efficiency, precision, and versatility. In combination with the operator's skills, they can handle even the most demanding tasks. With machines like CNC milling machines or CNC lathes with driven tools, the machining industry reaches new levels of advancement.

By choosing machines from our range of industrial machines (including woodworking machines), you can be sure of durability and reliability.

Conclusion

We have explained what a CNC lathe is, what a CNC lathe operator does, and where CNC lathes are used. These are key components of modern industry. To learn more, explore Cormak’s wide range of machines. They make production more precise, efficient, and modern.