What does the weld strength test look like?

Welding is a process of joining metal materials that creates a durable and solid connection. Both execution and weld strength are key factors. Weld quality testing is an essential step to ensure that the joint fulfills its function and won’t fail under mechanical stress. Today, we’ll explore methods for testing weld strength and learn how quality control techniques ensure robust welded joints.

In this article, you’ll find:

- Weld strength - why is it so important?

- Which weld is the strongest?

- What are the methods for testing weld strength?

- Choosing the right welding accessories

Weld strength - why is it so important?

Weld strength refers to the joint’s ability to withstand mechanical loads (e.g., tension, compression) without cracking or weakening. This parameter determines the durability of the weld and the entire structure. High weld strength ensures structural safety and resistance to damage. Various testing methods exist, depending on material type, application, and technical requirements.

Which weld is the strongest?

When determining the strongest weld, consider the material being joined. Common materials include stainless steel, carbon steel, and aluminum. The strongest weld depends on the material and welding technique. For stainless steel, TIG (tungsten inert gas) welding offers high precision and strength. For aluminum, laser welders paired with proper accessories provide exceptional quality and joint strength.

What are the methods for testing weld strength?

Weld testing is critical for quality control. Common methods include:

1. Ultrasonic weld testing

Ultrasonic testing uses high-frequency sound waves to inspect welds. Ultrasonic waves penetrate the weld, and reflected waves are analyzed to detect defects like cracks, porosity, or incomplete fusion. This non-destructive method is fast and precise, ideal for automotive, aerospace, and steel structures.

2. Radiographic weld testing

Radiographic testing uses X-rays or gamma rays to examine weld internal structures. This method provides detailed images, revealing cracks, porosity, or material flow issues. Radiographic testing is highly advanced but time-consuming and costly. It ensures unmatched accuracy in defect detection.

3. Other weld quality testing methods

Additional methods include:

-

Visual inspection - Evaluates surface defects like cracks, overheating, or unevenness.

-

Mechanical testing - Includes tensile, hardness, and bend tests to measure actual weld strength.

Weld testing and industrial machinery

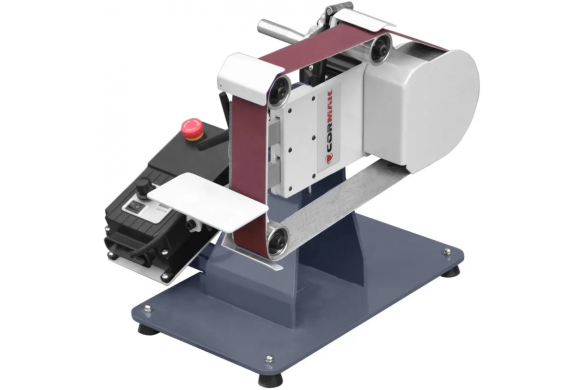

Weld strength testing is closely tied to metalworking machines. Proper pre-welding metal treatment and equipment like laser welders impact weld quality. High-quality machines from industrial machinery manufacturer Cormak ensure precise material preparation, enhancing weld integrity.

Choosing the right welding accessories

Achieving strong welds requires proper welding accessories. These tools enhance safety and precision, including protective gear and process-monitoring equipment.