Welding stainless steel, or how and with what to weld stainless.

Welding stainless steel is a process that requires a precise approach and appropriate equipment. Due to the properties of this material, such as corrosion resistance and high-temperature tolerance, the stainless steel welding process requires special techniques to ensure the durability and strength of the weld. Today, we will examine how to weld stainless steel, which welding methods to use, and what industrial machinery is essential for this task.

From this article, you will learn:

- What distinguishes stainless steel from other types of steel?

- Can stainless steel be welded?

- How to weld stainless steel?

- Technology for welding stainless steel

What distinguishes stainless steel from other types of steel?

Stainless steel is an alloy containing at least 10.5% chromium, which gives it exceptional corrosion resistance. For this reason, welding stainless steel poses additional challenges for welders, particularly in preserving this resistance post-welding. It is crucial to avoid overheating the material, as this can remove the steel's anti-corrosive properties.

Can stainless steel be welded?

If you are wondering whether stainless steel can be welded, the answer is yes – stainless steel can be welded, but it requires appropriate methods and equipment. Welding stainless steel requires temperature control during welding to avoid damaging the material’s structure, which could compromise its corrosion resistance. Therefore, it is essential to use modern equipment such as TIG welders, MIG/MAG welders, or laser welding machines, which enable precise and safe welding.

How to weld stainless steel?

If you are wondering how to weld stainless steel, the answer is not straightforward, as it depends on the type of stainless steel, material thickness, and the weld’s intended purpose. In this case, the choice of welding method and equipment plays a key role. Several popular techniques are used for welding stainless steel, such as:

-

TIG welding (Tungsten Inert Gas) – ideal for precise welds on thin materials, ensuring high-quality results. TIG welding produces clean, aesthetic welds without contamination risks.

-

MIG/MAG welding (Metal Inert Gas/Metal Active Gas) – a fast method, excellent for welding stainless steel in a shielding gas environment. High-quality welding wire and appropriate shielding gas are critical here.

-

Shielded metal arc welding (SMAW) – less common for stainless steel but usable in situations without access to shielding gas.

-

Laser welding of stainless steel – one of the latest technologies, enabling precise and fast welding. Laser welding machines produce high-quality welds with minimal heat impact on the material.

Technology for welding stainless steel

Stainless steel welding technology relies on selecting appropriate methods, machines, and welding accessories. Each method has advantages and disadvantages depending on technical requirements and final product quality. For example, laser welding of stainless steel is a technology that allows fast and precise welding with minimal heat impact on the material, which is crucial for stainless steel.

Welders for stainless steel welding

Choosing the right welders for stainless steel is critical to ensure high-quality and durable welds. TIG and MIG/MAG welders are the most commonly used devices. It is worth investing in machines that provide arc stability, precise parameter settings, and proper gas shielding to achieve durable and aesthetic welds.

If you are looking for a trusted industrial machinery manufacturer, Cormak offers a wide range of machines and equipment perfect for stainless steel welding. Their portfolio includes laser welders and MIG/MAG welders, enabling accurate and safe stainless steel welding.

Welding accessories are essential for any welding station. Depending on the chosen method, you may need items such as electrodes, welding wire, shielding gas, or protective gloves. Cormak provides a wide selection of welding accessories to ensure safety and high-quality work.

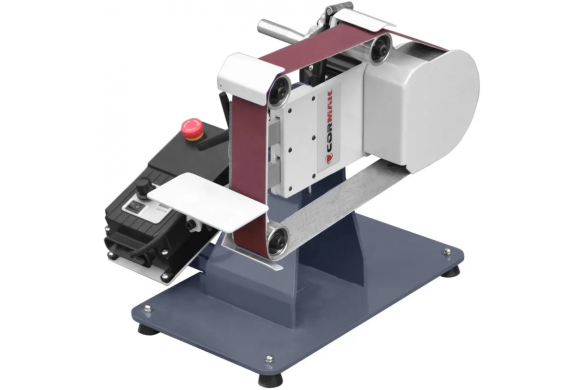

Metalworking machines

Additional material processing is often necessary during stainless steel welding. Metalworking machines like band saws, drills, or grinders enable precise cutting, drilling, and weld smoothing, which are vital for achieving aesthetic and durable results. Cormak offers modern industrial machines to ensure accuracy and efficiency at every stage.

Summary

Welding stainless steel requires proper technology, equipment, and expertise. The choice of method depends on the project’s specifics.

If you need stainless steel welding equipment, Cormak’s website features useful models of laser fume extractors and other devices.